Aquatic water aerator

An aeration device and a technology for aquaculture water, applied in water aeration, fish farming, degassed water/sewage treatment, etc., can solve problems such as inability to effectively remove carbon dioxide, difficulty in obtaining pure oxygen, uneven bubbles, etc., and achieve reduction The effect of water circulation rate, improvement of water quality in aquaculture pond, and good pushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

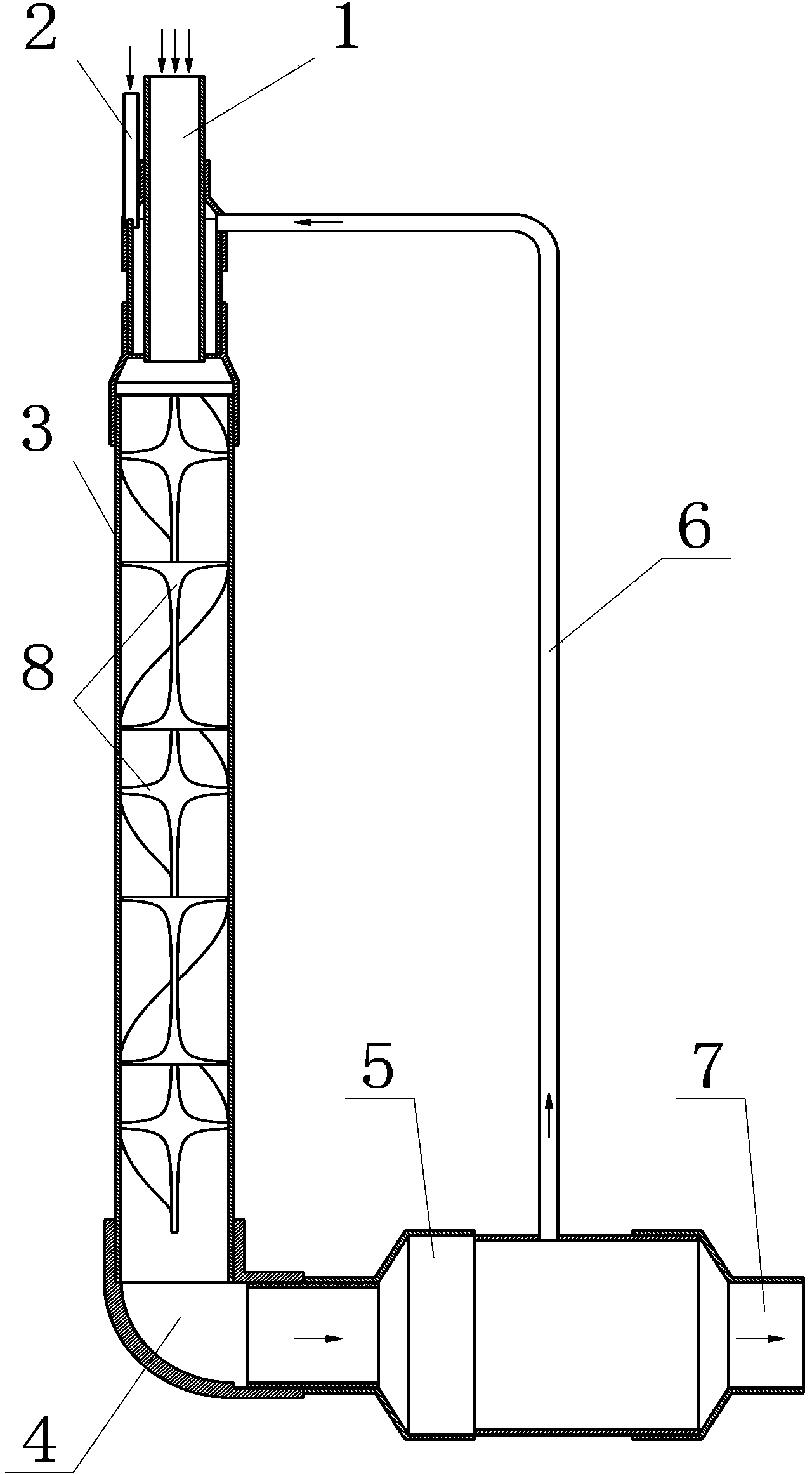

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] figure 1 Among them, the pressurized water inlet pipe 1 and the compressed air inlet pipe 2 are inserted into the gas-liquid mixing pipe 3 axially along the vertically arranged gas-liquid mixing pipe 3 respectively, and communicate with the upper end of the inner chamber of the gas-liquid mixing pipe 3 .

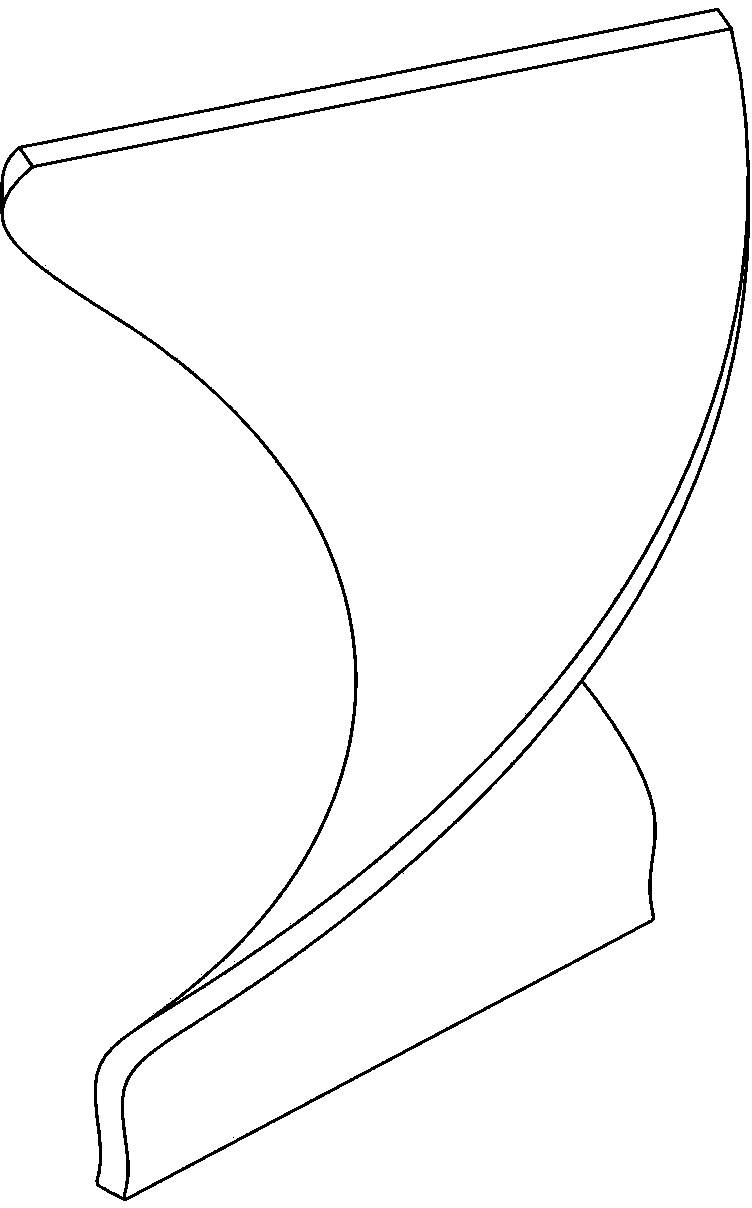

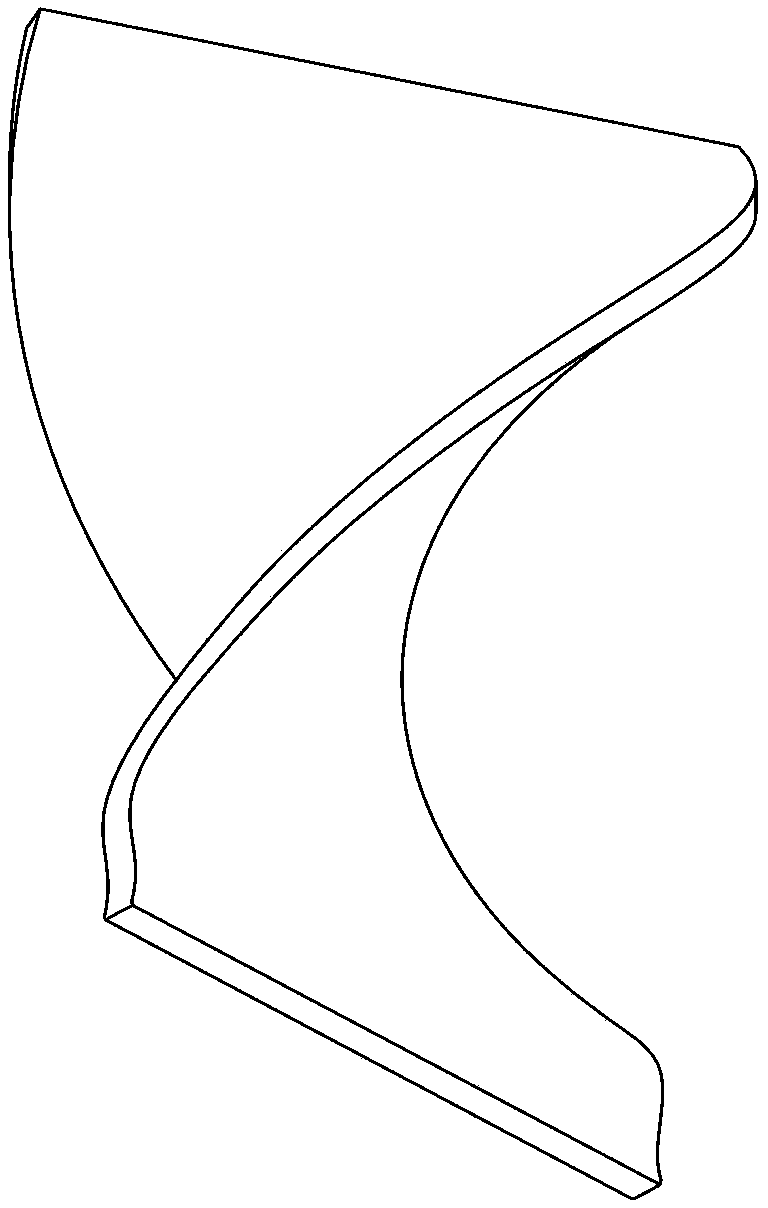

[0041] The inner chamber of the gas-liquid mixing pipe 3 is in the shape of a circular tube. In the gas-liquid mixing pipe 3 below the pressure water inlet pipe 1 and the compressed air inlet pipe 2, five helical blades 8 are stacked up and down. The helical blades 8 are fixed on the gas-liquid mixing pipe 3. In the mixing tube 3, each helical blade 8 is formed by twisting the upper and lower sides of a flat blade in reverse, the twist angle is 180-360 degrees, and the outer edge of the helical blade 8 matches the inner cavity of the gas-liquid mixing tube 3, The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com