Method for determining hole pattern parameters of continuous mill by mechanical drawing

A technology of mechanical drawing and continuous rolling mill, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of complicated calculation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

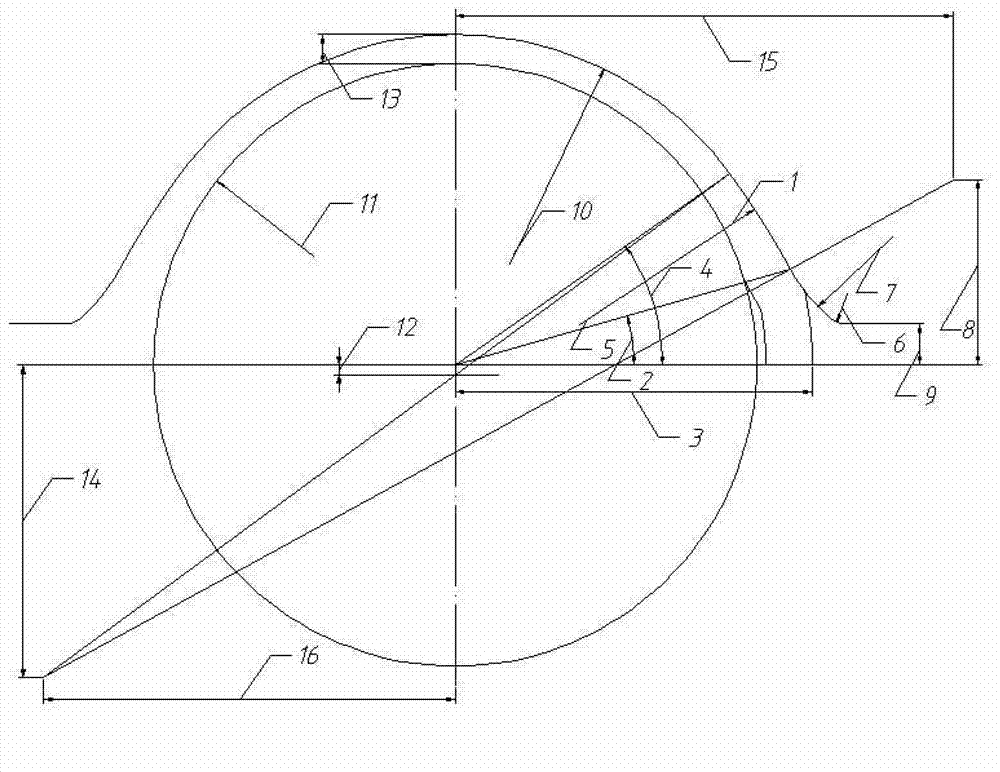

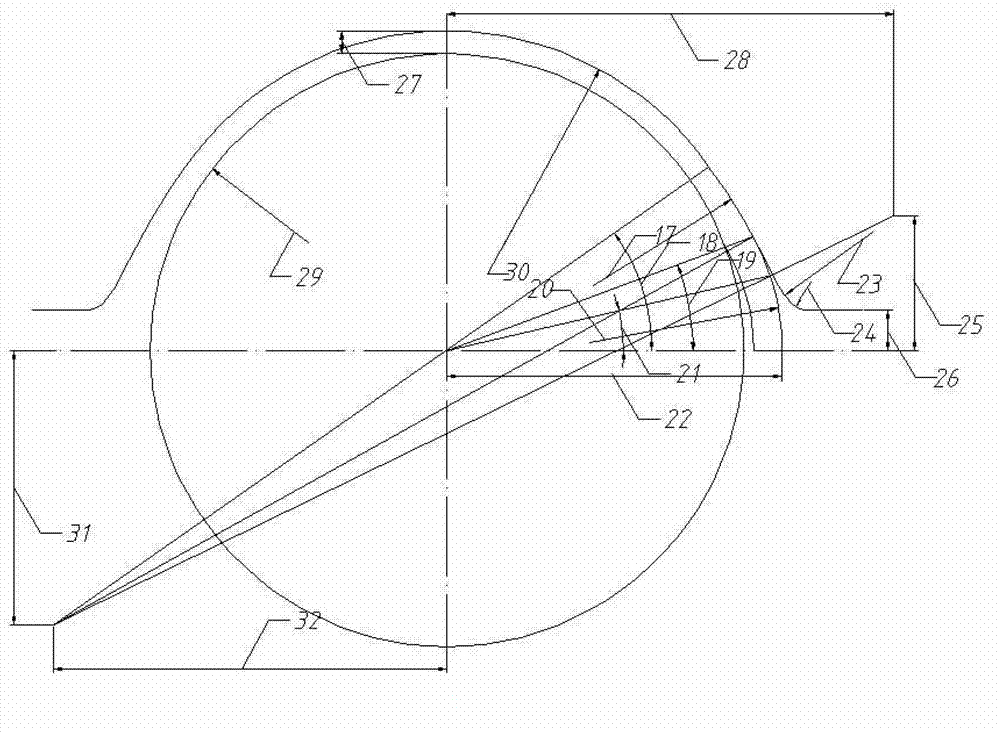

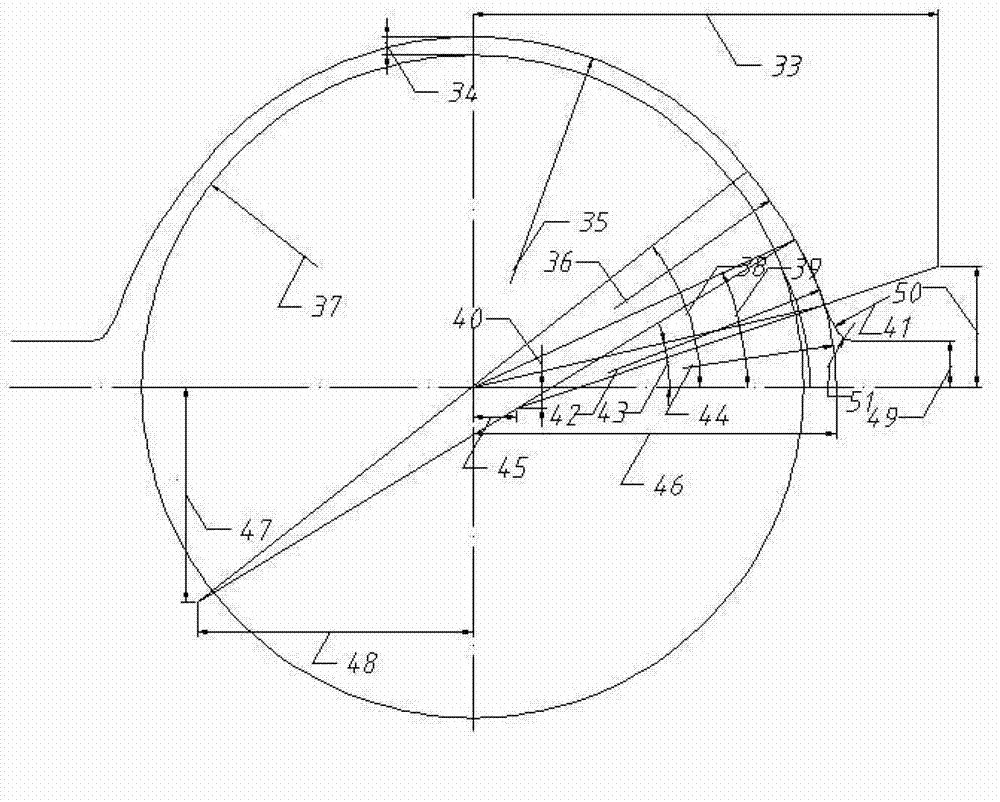

[0058] Such as Figure 1-Figure 5 Shown in conjunction with, 1. of the present invention draws a kind of method that determines continuous rolling mill pass parameter with mechanical drawing, and its concrete steps are as follows:

[0059] The first step is to fill in the parameters and required parameters of the capillary tube and the blank tube after rolling into the pass parameter table according to the rolling table; such as: outer diameter, wall thickness, elongation, mandrel diameter, etc.

[0060] In the second step, fill in some parameters and regular relations of the pass design into the pass parameter table and calculate the corresponding parameters; the part parameters and regular relations are the elongation rate and the wall thickness of the bottom of the groove; the pass parameters of the pass are Height 2R, hole throat radius R1 of the pass parameter, eccentricity coefficient of the pass parameter, eccentric distance of the pass parameter; the first breakaway angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com