Manufacture method of laser chip

A manufacturing method and laser technology, which are applied to the structure of optical waveguide semiconductors and other directions, can solve the problems of low yield of single-mode lasers and low yield of laser chips, and achieve the effect of saving costs and simplifying design steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

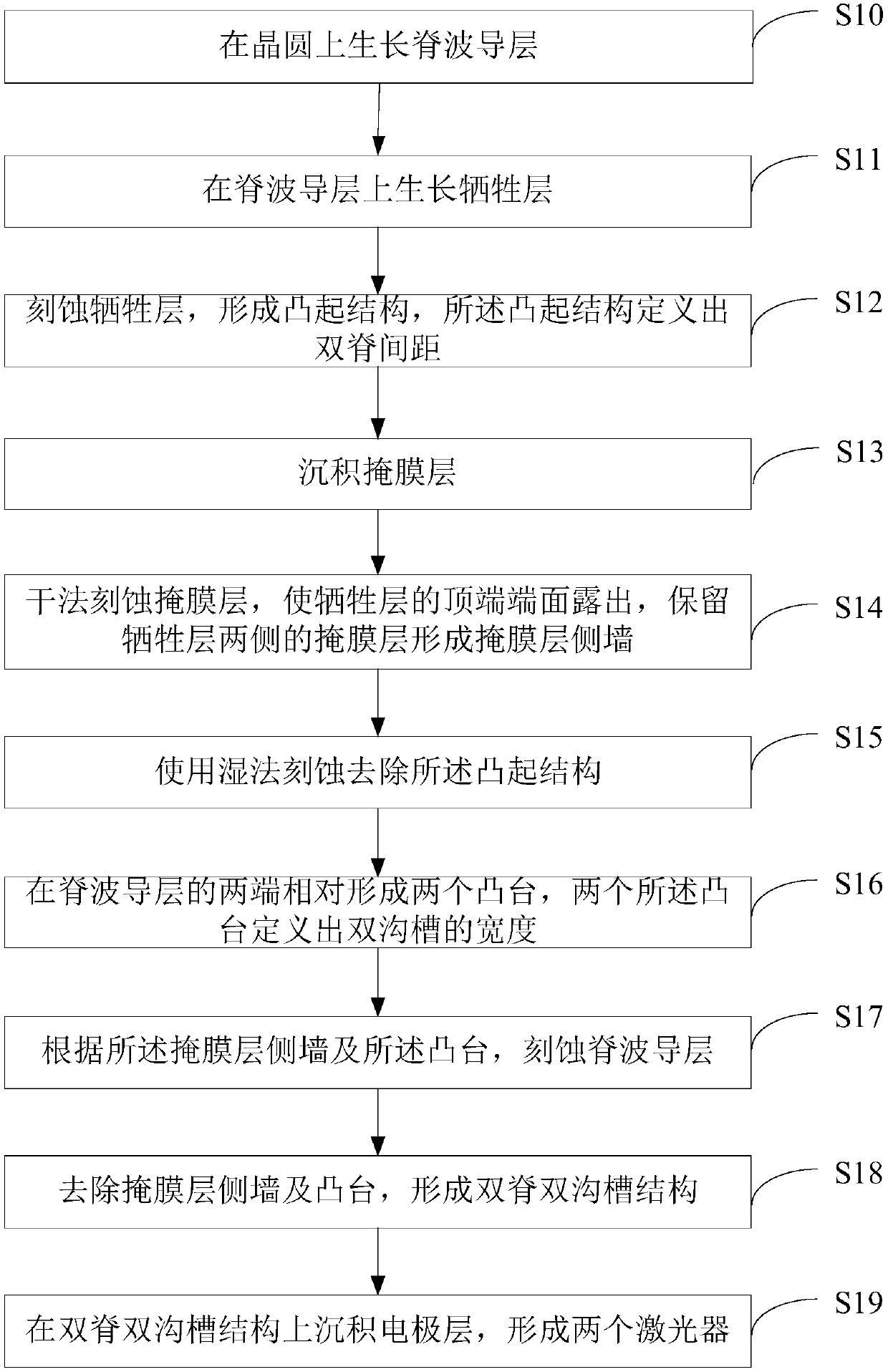

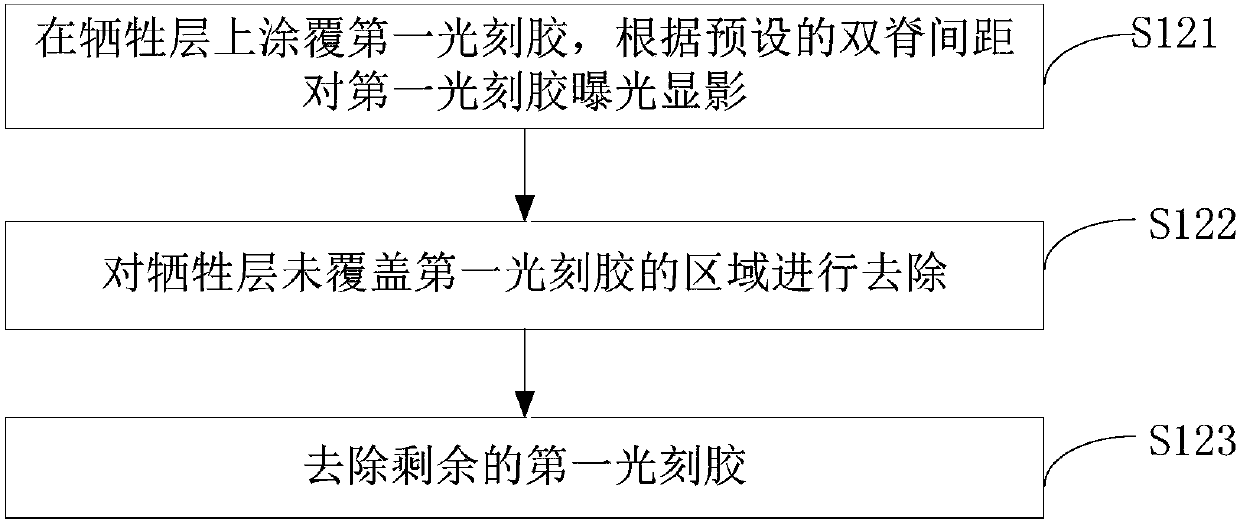

[0032] see figure 1 , the invention provides a kind of manufacturing method of laser chip, comprises steps:

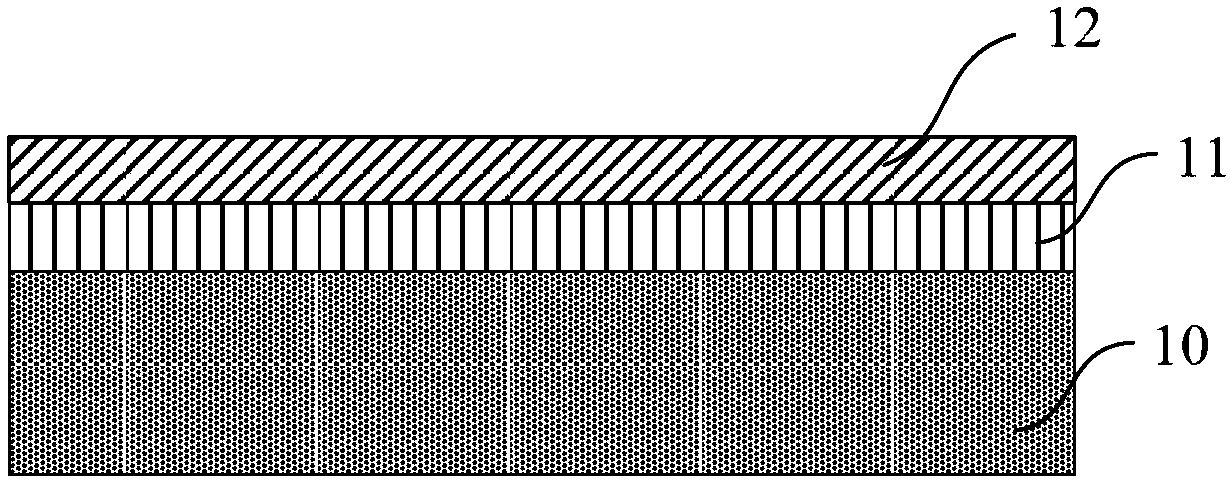

[0033] Please also see figure 2 , step S10 , growing a ridge waveguide layer 11 on the wafer 10 .

[0034] Ridge waveguide layer 11 is located on wafer 10 . Wafer 10 is suitable for various types of semiconductor lasers. Specifically, the ridge waveguide layer 11 generally includes a top layer and a bottom layer. The top layer is an InGaAs layer, and the bottom layer is an indium phosphide (InP) layer. Wherein, the thickness of the top laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com