Punching equipment used for forming carrier tape

A kind of equipment and punching technology, which is applied in the field of punching equipment for carrier tape forming, can solve problems such as damage and degumming of cover tape, and achieve the effects of reducing the loss of manpower and material resources, improving work efficiency, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

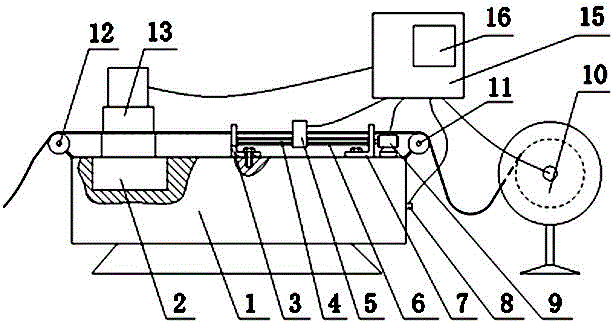

[0025] Such as figure 1 As shown, the punching equipment used for forming the carrier tape includes a base 1, a punching device 13, a traction device, a winding device 10 and a control box 15:

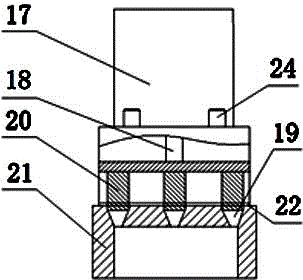

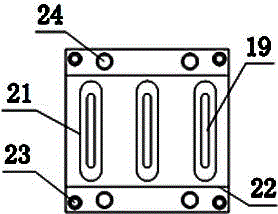

[0026] Such as figure 2 with image 3 As shown, the punching device 13 is installed on the base 1, the punching device 13 includes a die 21, a punch 20 cooperating with the die 21, a push rod 18 and a cylinder 17, the punch 20 and the die 21 The material is imported hard alloy or high-quality alloy steel. The die 21 is fixed on the base 1 by countersunk head socket head cap screws 23. The top of the die 21 is provided with a through groove 22 along the horizontal direction, and the die 21 is also provided with a waste diversion groove. 19. The die 21 is provided with a guide post ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com