Mono-blocked propionyloxy silicone resin and preparation method thereof, conductive adhesive containing the same and preparation method thereof

A technology of terminal propionyloxy and adhesive, which is applied in conductive adhesives, adhesives, polymer adhesive additives, etc. Low requirements for bonding and curing equipment, easy to popularize and apply, and excellent effect of cured product elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

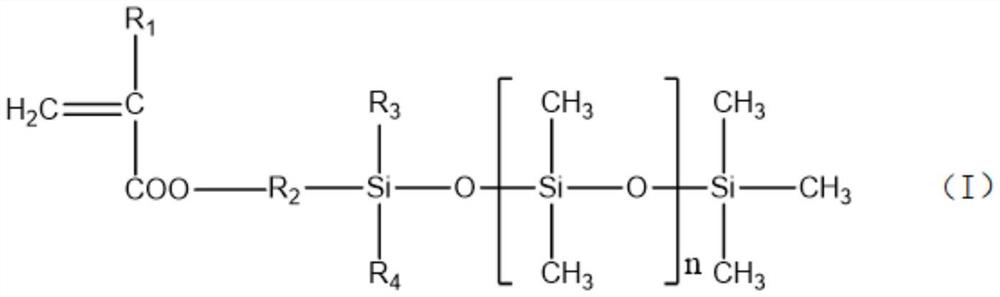

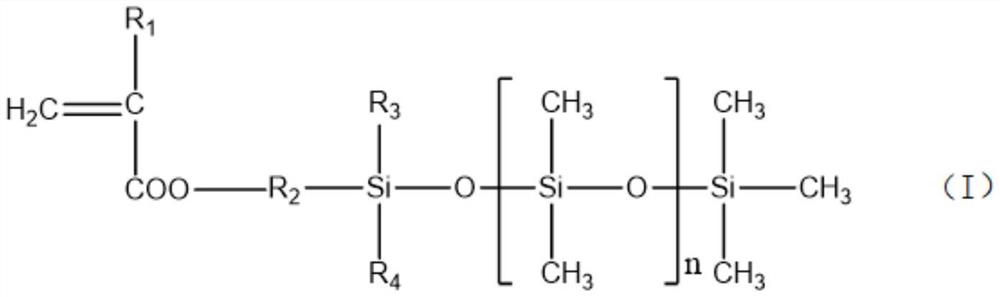

[0046] This embodiment provides a kind of single-end propionyloxy silicone resin, the structural formula is as shown in formula (I):

[0047]

[0048] Among them, R 1 for CH 3 ;

[0049] R 2 for CH 2 CH 2

[0050] R 3 for CH 3 ;

[0051] R 4 for CH 3 ;

[0052] n is 500.

[0053] The preparation method of the above-mentioned single-end propionyloxy silicone resin comprises the following steps:

[0054] React hydroxyl-containing silane and vinyl-containing silane under the action of dibutyltin dilaurate. After the viscosity of the system reaches 1000-50000mPa·S, add quinone to terminate the reaction, and the obtained reaction product is cleaned and distilled by alcohol. That is, the mono-blocked propionyloxy silicone resin is obtained.

[0055] Wherein, the molar ratio of hydroxy-containing silane, vinyl-containing silane, catalyst, and hydroquinone is 10:10:0.5:0.5.

Embodiment 2

[0057] The present embodiment provides a kind of modified silver powder, and its preparation method comprises the following steps: add 10g silver powder in the NaOH solution of 5kg, leave standstill for 12 hours after high-speed stirring reaction 3 hours, adopt pure water to wash 3 times, then adopt alcohol to wash 2 times, drying through a 450-mesh stainless steel sieve to obtain modified silver powder.

[0058] Wherein, the mass fraction of NaOH solution is 1%.

[0059] Wherein, the stirring reaction temperature is less than 50°C. If the reaction temperature is higher than 50°C, the fine particles of silver powder will fuse, changing the shape of the silver powder itself, and then affecting the viscosity and bonding strength of the conductive adhesive.

[0060] Wherein, the silver powder in this embodiment is the silver powder with the brand name of TC-505 produced by Japan Deli. The average particle size of the TC-505 silver powder produced by Japan Deli is 3 μm.

[0061...

Embodiment 3

[0063] The present embodiment provides a kind of modified silver powder, and its preparation method comprises the following steps: add 10g silver powder in the NaOH solution of 5kg, leave standstill for 12 hours after high-speed stirring reaction 3 hours, adopt pure water to wash 3 times, then adopt alcohol to wash 2 times, drying through a 450-mesh stainless steel sieve to obtain modified silver powder.

[0064] Wherein, the mass fraction of NaOH solution is 1%.

[0065] Wherein, the stirring reaction temperature is less than 50°C. If the reaction temperature is higher than 50°C, the shape of the silver powder itself will be changed.

[0066] Wherein, the silver powder in this embodiment is the silver powder with the brand name TCG-1 produced by Japan Deli. The average particle size of the TCG-1 silver powder produced by Japan Deli is 4.3 μm.

[0067] Further, the modified silver powder prepared in the present invention must be used up within 24 hours. During the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com