Numerical-control dual-rotation milling head for three-coordinate measuring machine

A three-coordinate measuring machine and double-rotation technology, which is applied to milling devices, measuring/indicating equipment, and milling machine equipment that can be installed on machine tools, can solve problems such as poor processing, reduce enterprise costs, and improve equipment utilization. The effect of ensuring the accuracy of repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

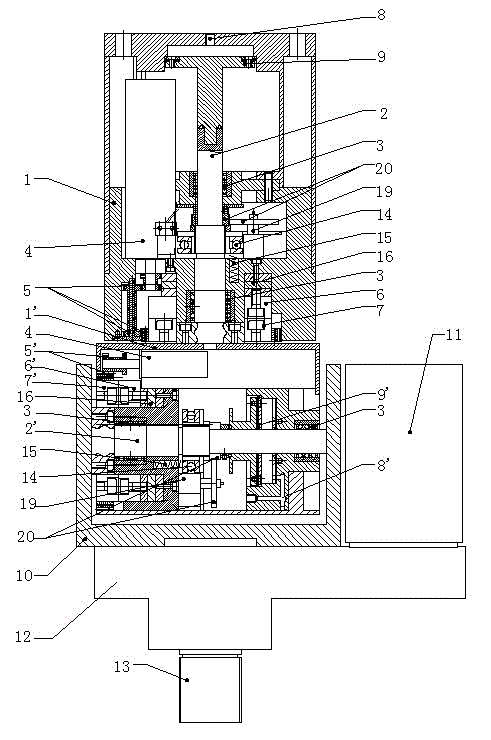

[0023] Embodiment 1: A numerically controlled double-rotating milling head for a three-coordinate measuring machine, including a B-axis assembly, an A-axis assembly, and a milling system. The B-axis assembly and the A-axis assembly are arranged perpendicular to each other, and the A-axis assembly is connected to the A-axis assembly through a mounting plate 10 Milling system connection, the B-axis assembly includes a B-axis housing 1 and a B-axis main shaft 2 disposed in the B-axis housing 1, a B-axis rotation assembly and a B-axis axial displacement assembly, and the B-axis main shaft 2 is installed on the B-axis housing 1 A dense ball bearing 3 is provided inside and between the B-axis housing 1. The B-axis rotating assembly includes a servo motor 4, a B-axis gear set 5, and an end sprocket assembly. Two toothed discs meshing, wherein the toothed disc 6 on the upper part of the B-axis is connected to the housing 1 of the B-axis, and the geared disc 7 on the lower part of the B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com