Cutting device for paper feed mechanism

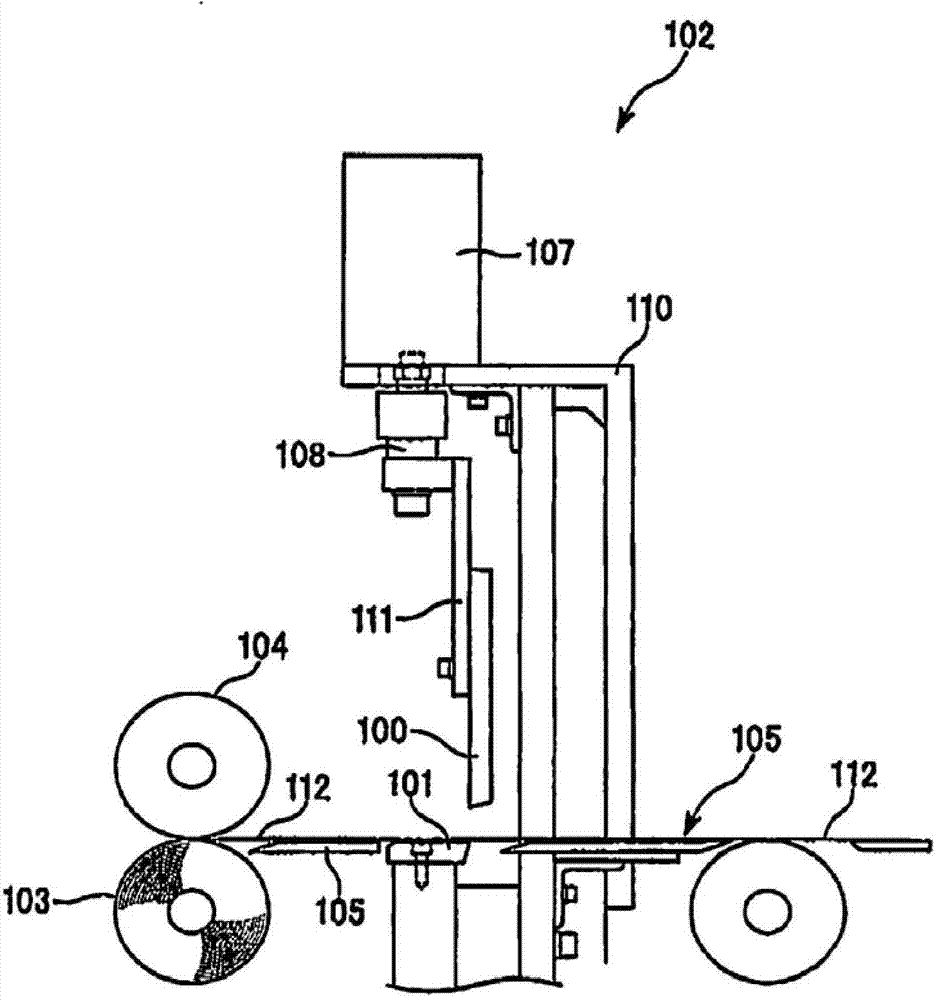

A cutting device, paper sheet technology, applied in packaging, papermaking, transportation and packaging, etc., can solve problems such as the meshing deviation of the upper knife 100, the structural rigidity of the thick plate (insufficient torsional rigidity and bending rigidity, deformation of the base member 111, etc.) , to achieve the effect of improving safety, good sharpness and inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] Hereinafter, a first embodiment of the cutting device of the present invention will be described with reference to the drawings, but the present invention is not limited to the embodiment described below.

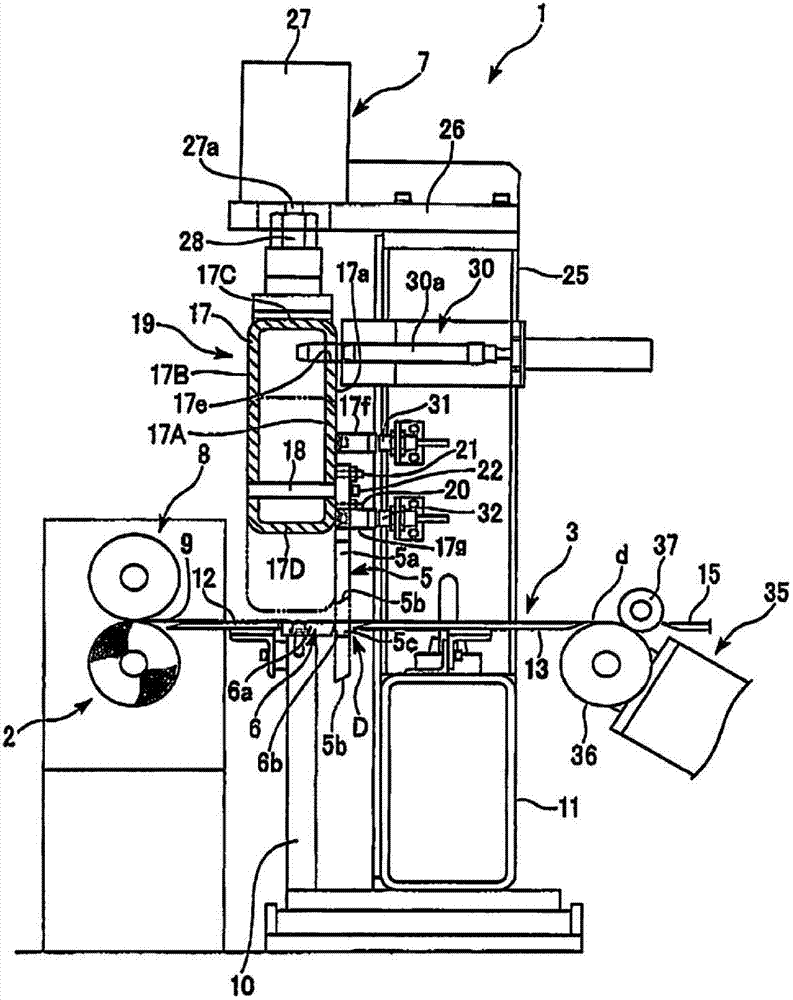

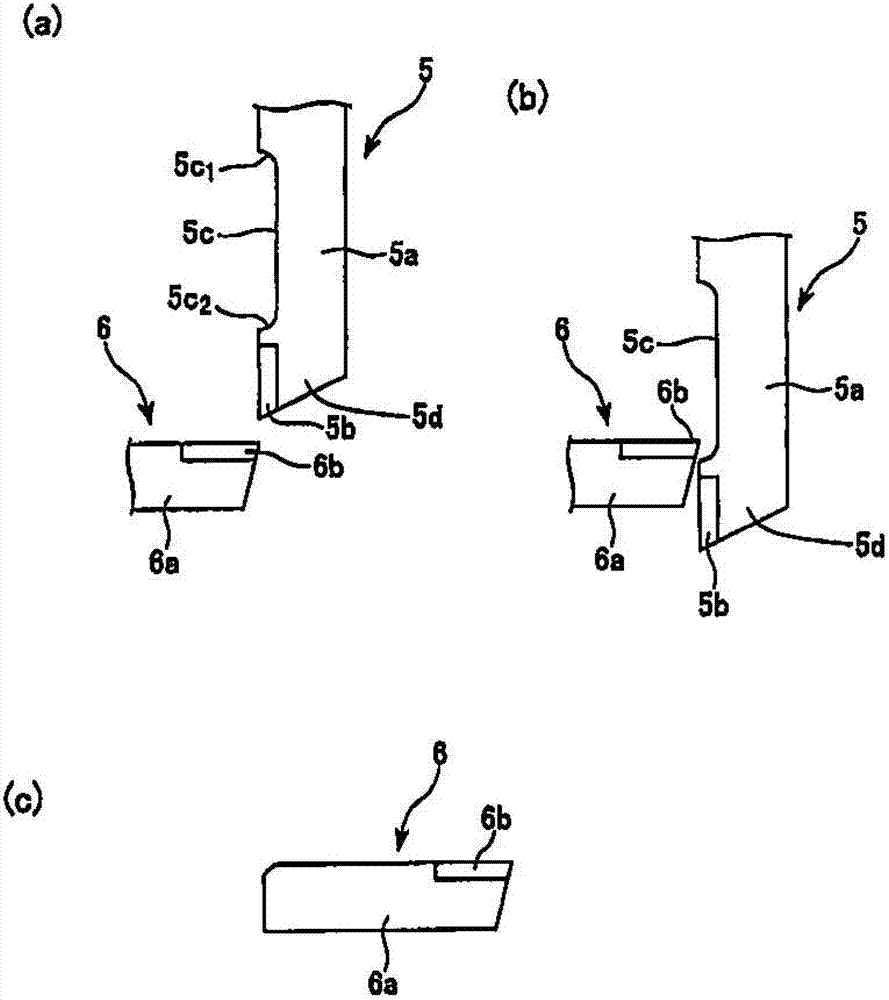

[0039] figure 1 The overall structure of the sheet cutting device according to the first embodiment of the present invention is schematically shown. The cutting device 1 of this embodiment is mainly composed of the following structure: a sheet supply roller 2 arranged in the horizontal direction; The conveying path 3 of the sheet class is erected on the side of the supply roller 2 along the horizontal direction; figure 2 The upper knife (cutting knife) 5 and the lower knife (cutting knife) 6, which are enlarged in the middle, are arranged above and below the conveying path 3 in the middle of the conveying path 3; the driving mechanism (elevating mechanism) 7 makes the above-mentioned upper knife 5 Move in the up and down direction.

[0040] The above-mentioned su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com