Energy-saving bias-reduction multi-wire diamond saw

A beaded saw and beaded rope technology, used in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of large biasing moment, heavy sawing system, hidden danger of machine safety, etc. Lightening, effect of saving the number of hydraulic/pneumatic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

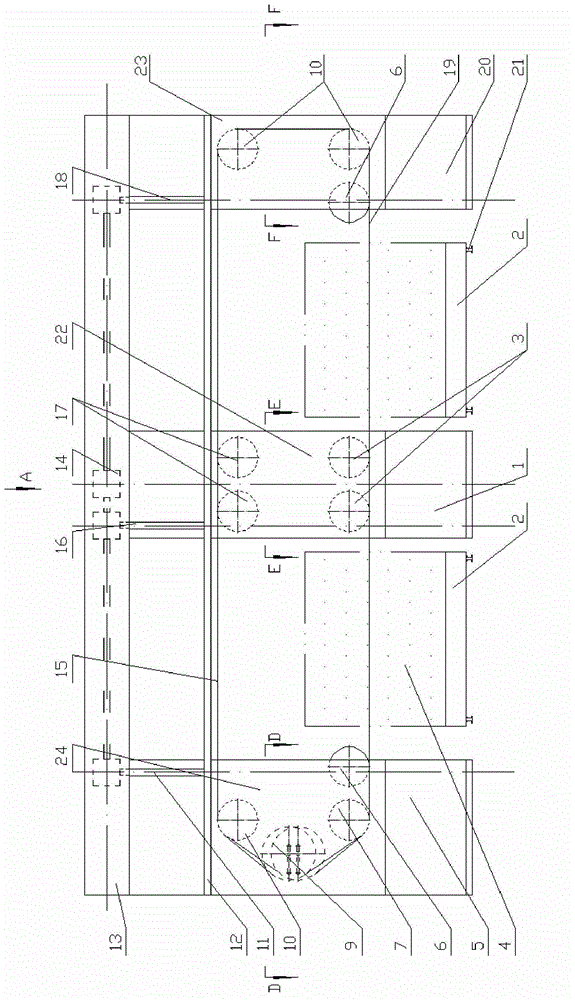

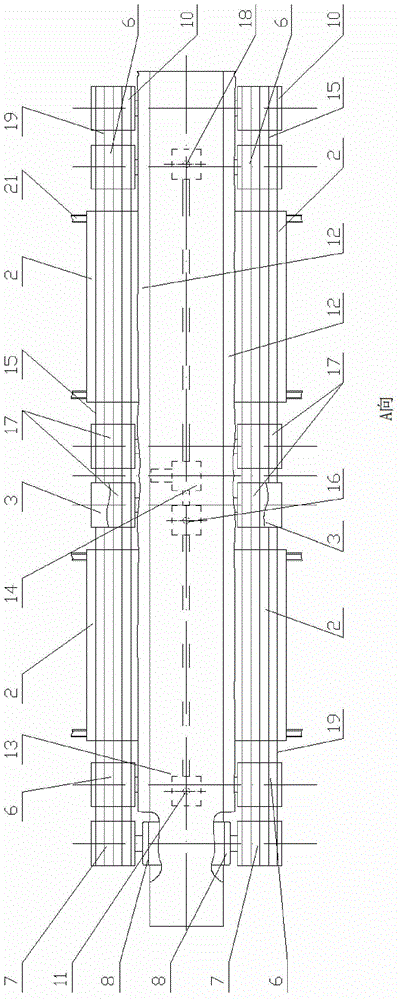

[0037] like figure 1 , figure 2 , Figure 13 and Figure 14 as shown, figure 1 and figure 2 It is the scheme that the two sawing systems 15 of Embodiment 1 are installed symmetrically, Figure 13 and Figure 14It is the solution for the corresponding installation of the two sawing systems 15 in Embodiment 1. The energy-saving and deflection-reducing multi-rope bead saw of the present invention adopts the solution that four block cars 2 are arranged under the two sawing systems 15 at the same time. The four block cars are arranged in two groups in parallel and two groups in series. The machine has a large frame 5, a medium frame 1 and a small frame 20 each, and the large frame 5, the medium frame 1 and the small frame 20 are shared. A roof beam 13 is connected into a double door structure, and the large frame 5, the middle frame 1, and the small frame 20 are respectively equipped with a large lifting sliding sleeve 24, a middle lifting sliding sleeve 22 and a small lift...

Embodiment 2

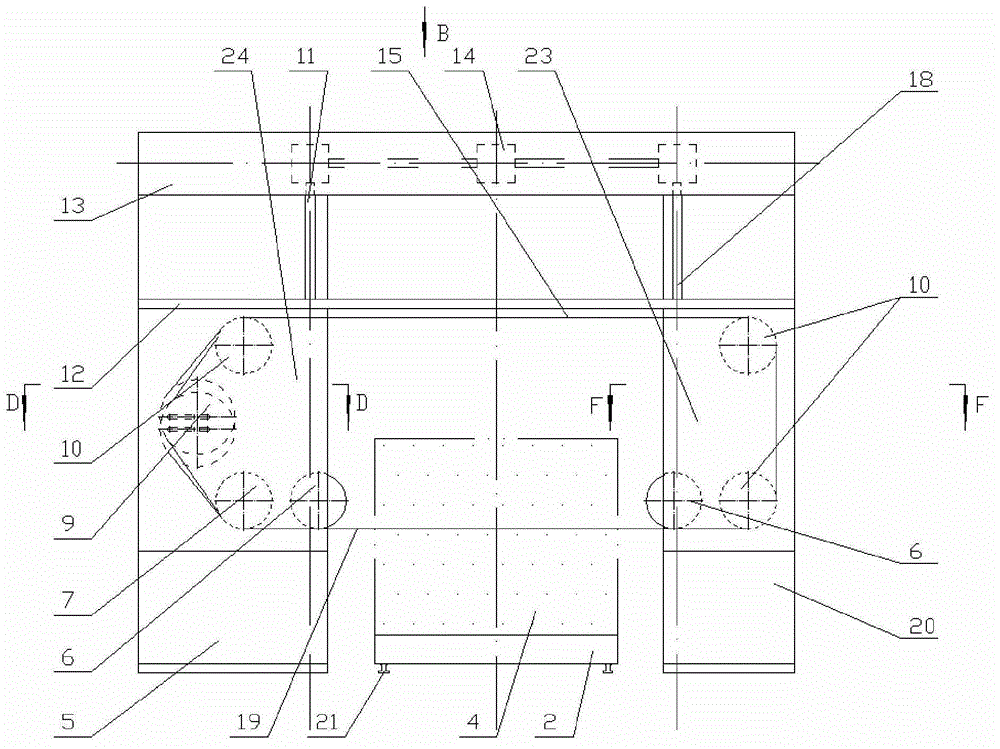

[0039] like image 3 , Figure 4 , Figure 15 and Figure 16 as shown, image 3 and Figure 4 For the scheme that two sawing systems 15 of embodiment two are installed symmetrically, Figure 15 and Figure 16 It is the solution for the corresponding installation of the two sawing systems 15 in the second embodiment. The energy-saving and deflection-reducing multi-rope bead saw of the present invention adopts the solution that two block cars are arranged under the two sawing systems at the same time. The block carts are arranged in series. The machine has a large frame 5 and a small frame 20 each. Each frame shares a top beam 13 and is connected into a door-shaped structure. The large frame 5 and the small frame 20 are respectively equipped with a large lift Sliding sleeve 24 and small lifting sliding sleeve 23, large lifting sliding sleeve and small lifting sliding sleeve are respectively connected with large screw mechanism 11 and small screw mechanism 18 and driven by ...

Embodiment 3

[0041] like Figure 5 and Image 6 As shown, the energy-saving and bias-reducing multi-rope bead saw of the present invention adopts the scheme that two block cars 2 are arranged under a sawing system 15 at the same time. The two block cars are arranged in parallel, and the machine has a large machine Frame 5, middle frame 1 and small frame 20 each one, large frame 5, middle frame 1 and small frame 20 share a top beam 13 to be connected into a double door structure, large frame 5, middle frame 1 and the small frame 20 are respectively configured with a large lifting sliding sleeve 24, a middle lifting sliding sleeve 22 and a small lifting sliding sleeve 23, and a large lifting sliding sleeve 24, a middle lifting sliding sleeve 22 and a small lifting sliding sleeve 23 are connected with the large screw mechanism 11 respectively. 1, the middle screw mechanism 16 is connected with the small screw mechanism 18 and driven by the latter along the large horizontal guide rail 25, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com