Dual-adjustment unpowered supernatant quantitative discharging device

A technology of discharge device and double adjustment, which is applied in the directions of grease/oily substance/float removal device, liquid separation, separation method, etc., can solve the problems of high maintenance cost and large power consumption of submersible pump, so as to achieve no maintenance cost and operation. The effect of low maintenance cost and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

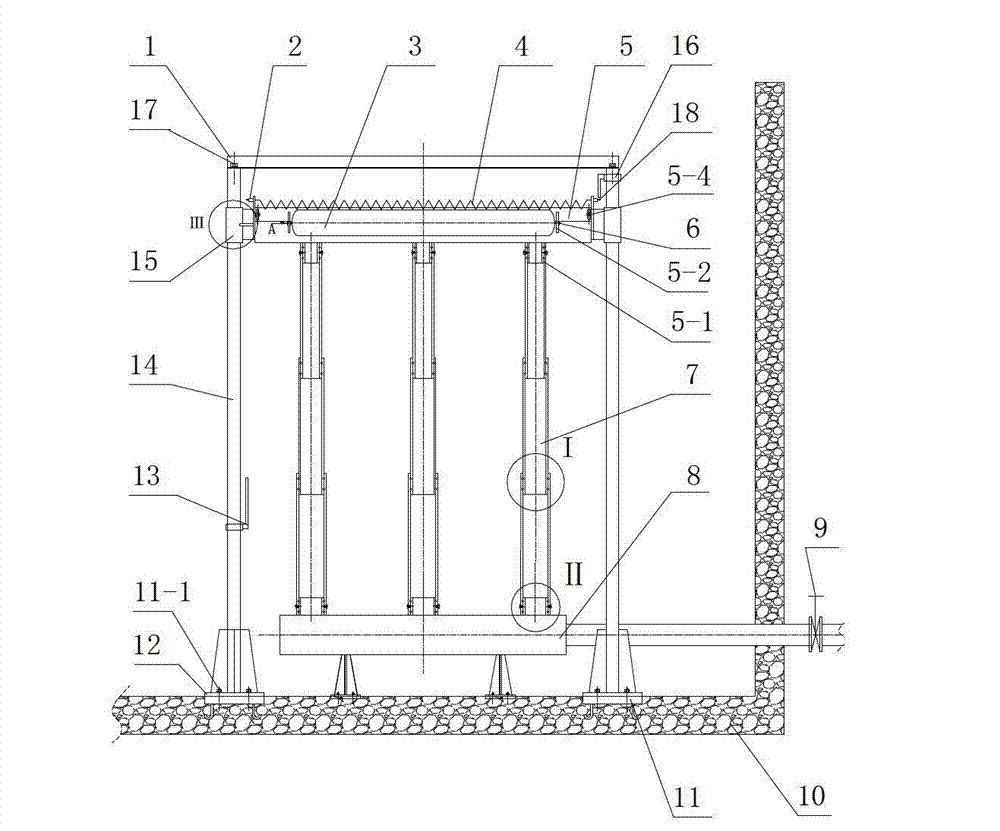

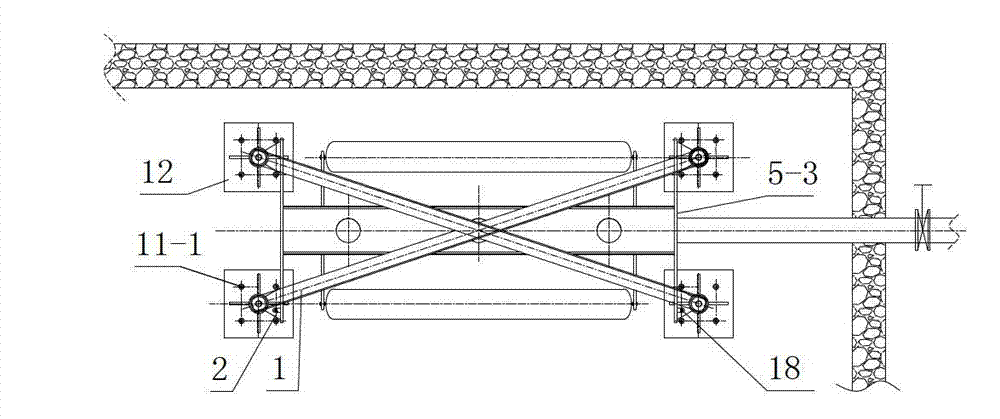

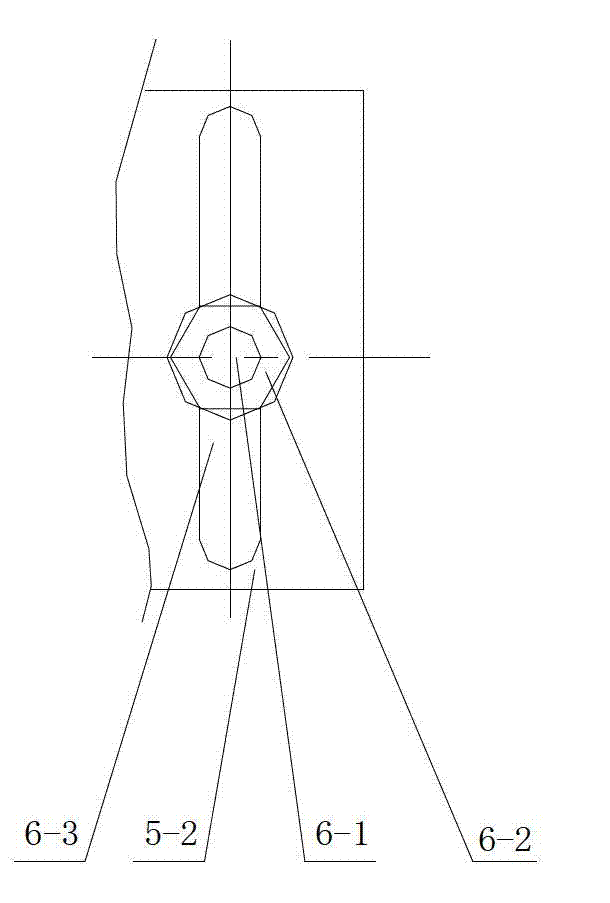

[0030] Double-regulated unpowered supernatant quantitative discharge device

[0031] 1. The double-adjustment non-powered supernatant quantitative discharge device includes a fixed frame on the slideway 1, a position switch 2, a buoy 3, a water distribution weir plate 4, a drainage box 5, a buoy adjustment device 6, a drainage expansion pipe 7, and a water collection pipe 8 , electric valve 9, advection oil separation sedimentation tank 10, embedded mounting seat 11, bracket slide base 12, lower limiter 13, bracket slideway 14, drainage box guide sleeve 15, upper limiter 16, bolt 17, drainage box Outlet pipe 5-1, buoy adjustment bracket 5-2, drainage tank end plate 5-3, weir plate adjustment device 5-4, buoy adjustment bolt 6-1, buoy adjustment nut 6-2, bolt hole 6-3, telescopic Pipe a7-1, telescopic pipe b7-2, gland bolt 7-3, gland 7-4, O-ring 7-5, set bolt 7-6, water collection pipe joint 8-1, water collection pipe body 8 -2, pre-embedded mounting seat bolts 11-1; it is cha...

Embodiment 2

[0037] Double-regulated unpowered supernatant quantitative discharge device

[0038] 1. The double-adjustment non-powered supernatant quantitative discharge device includes a fixed frame on the slideway 1, a position switch 2, a buoy 3, a water distribution weir plate 4, a drainage box 5, a buoy adjustment device 6, a drainage expansion pipe 7, and a water collection pipe 8 , electric valve 9, advection oil separation sedimentation tank 10, embedded mounting seat 11, bracket slide base 12, lower limiter 13, bracket slideway 14, drainage box guide sleeve 15, upper limiter 16, bolt 17, drainage box Outlet pipe 5-1, buoy adjustment bracket 5-2, drainage tank end plate 5-3, weir plate adjustment device 5-4, buoy adjustment bolt 6-1, buoy adjustment nut 6-2, bolt hole 6-3, telescopic Pipe a7-1, telescopic pipe b7-2, gland bolt 7-3, gland 7-4, O-ring 7-5, set bolt 7-6, water collection pipe joint 8-1, water collection pipe body 8 -2, pre-embedded mounting seat bolts 11-1; it is cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com