Novel stone floor and production process thereof

A stone-wood floor and production process technology, applied in the field of new stone-wood floor and its production process, can solve the problems of high market price, unfavorable popularization and application, and complicated processing procedures of stone-wood floor, so as to optimize the ratio of raw materials and improve Process performance, the effect of streamlining the processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation materials for the novel stone-wood floor include the following raw materials and parts by weight: 66 parts of heavy calcium carbonate, 50 parts of polyvinyl chloride resin, 0.8 parts of lead stearate, 2 parts of chlorinated polyethylene, 2 parts of dibutyl Esters are 2 parts.

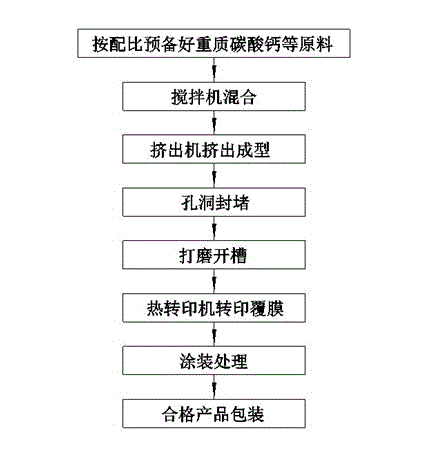

[0012] The production process of the new stone wood flooring is as follows: figure 1 As shown, the details are as follows:

[0013] 1) Preparation of raw materials: Prepare various raw materials according to the ratio of raw materials;

[0014] 2) Mixing and stirring: Mix the raw materials according to the preset ratio and mix them in a high-speed mixer. The stirring temperature is 130°C and the stirring time is 20 minutes;

[0015] 3) Extrusion molding: Add it into the extruder after the mixing is completed, and directly extrude it when the temperature of the raw material drops to 35°C, without granulation process. During the extrusion process, it is cut according to the size ...

Embodiment 2

[0023] The preparation materials for the novel stone-wood floor include the following raw materials and parts by weight: 90 parts of heavy calcium carbonate, 31 parts of polyvinyl chloride resin, 0.2 part of lead stearate, 0.2 part of chlorinated polyethylene, Esters are 0.2 parts.

[0024] The production process of the novel stone-wood floor described in embodiment 2 is the same as that in embodiment 1.

[0025] After the final inspection of the obtained product, the water absorption thickness expansion rate, surface wear resistance, combustion performance, radioactivity and other performance indicators of the product obtained in this embodiment are all better than the existing stone wood flooring.

Embodiment 3

[0027] The preparation materials for the novel stone-wood floor include the following raw materials and parts by weight: 75 parts of heavy calcium carbonate, 40 parts of polyvinyl chloride resin, 0.5 part of lead stearate, 1 part of chlorinated polyethylene, 1 part of ester.

[0028] The production process of the novel stone-wood floor described in embodiment 3 is the same as that in embodiment 1.

[0029] After the final inspection of the obtained product, the water absorption thickness expansion rate, surface wear resistance, combustion performance, radioactivity and other performance indicators of the product obtained in this embodiment are all better than the existing stone wood flooring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com