Heat-insulating self-cleaning glass coating

A glass coating and self-cleaning technology, used in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as few reports, and achieve the effects of low cost, wide application and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 1.5g sodium polyphosphate and add it to 80ml distilled water, add 10g ATO powder, 5g TiO 2 Powder. And adjust the pH of the system to 8. After stirring evenly, ultrasonically disperse for 15 minutes, and then stir on the FJ200 high-speed homogeneous disperser for 4 hours. Get ATO-TiO 2 The composite slurry has good dispersion stability, and no significant settlement has occurred after a long period of storage. Weigh 110g of water-based polyurethane (PUD-350, Shanghai Sisheng), and mix it with ATO-TiO 2 Mix the composite slurry evenly, add 1.5g of dispersant (Shenzhen Shuangcheng Trading Company, FT-206), 0.8g of sodium polyacrylate and 1.0g of methyl cellulose in sequence, then stir on a high-speed homogeneous disperser for 2 hours to obtain a coating, and then The paint is applied to the glass in a dipping-pulling method to obtain a uniformly coated and uniform heat-insulating self-cleaning glass film.

Embodiment 2

[0036] Weigh 2.5g sodium hexametaphosphate and add it to 100ml distilled water, stir rapidly and add 15g nano-ATO powder, 10g TiO 2 Powder. After adjusting the pH=6, ultrasonically disperse for 15 minutes, and then stir for 4 hours by a shear emulsification mixer. Get ATO-TiO 2 The composite slurry has good dispersion stability, and no significant settlement has occurred after a long period of storage. Weigh 150g of water-based polyurethane (PUD-350, Shanghai Sisheng), and mix it with ATO-TiO 2 Mix the composite slurry evenly, add 2.5g dispersant (FT-206), 1.4g polyether organosiloxane leveling agent (Shenzhen Shuangcheng Trading Company FL-3) and 1.6g methylcellulose in sequence, and then high-speed Disperse for 2 hours to obtain the coating, and then apply the coating to the glass by means of suspension coating to obtain a heat-insulating self-cleaning glass film with uniform coating and uniform film quality.

Embodiment 3

[0038] Weigh 12g nano ATO powder, 5g TiO 2 Powder and 1.5g sodium dodecylbenzenesulfonate. Add it into 90ml of distilled water, stir evenly, adjust the pH of the system to 8, then stir at high speed for 4~5h, and finally ultrasonically disperse for 15min. Get ATO-TiO 2 The composite slurry has good dispersion stability, and no significant settlement has occurred after a long period of storage. Weigh 200g of bisphenol-A type epoxy resin (EP 01661-310), mix it with the composite slurry, add 2.0g of dispersant (FT-206), 1.5g of polyether organosiloxane leveling (FL-3) and 1.8g of methyl cellulose, and then stirred at high speed for 2 hours to obtain the coating, which was coated on the glass by dipping and pulling to obtain a heat-insulating self-cleaning glass film with uniform coating and uniform film quality.

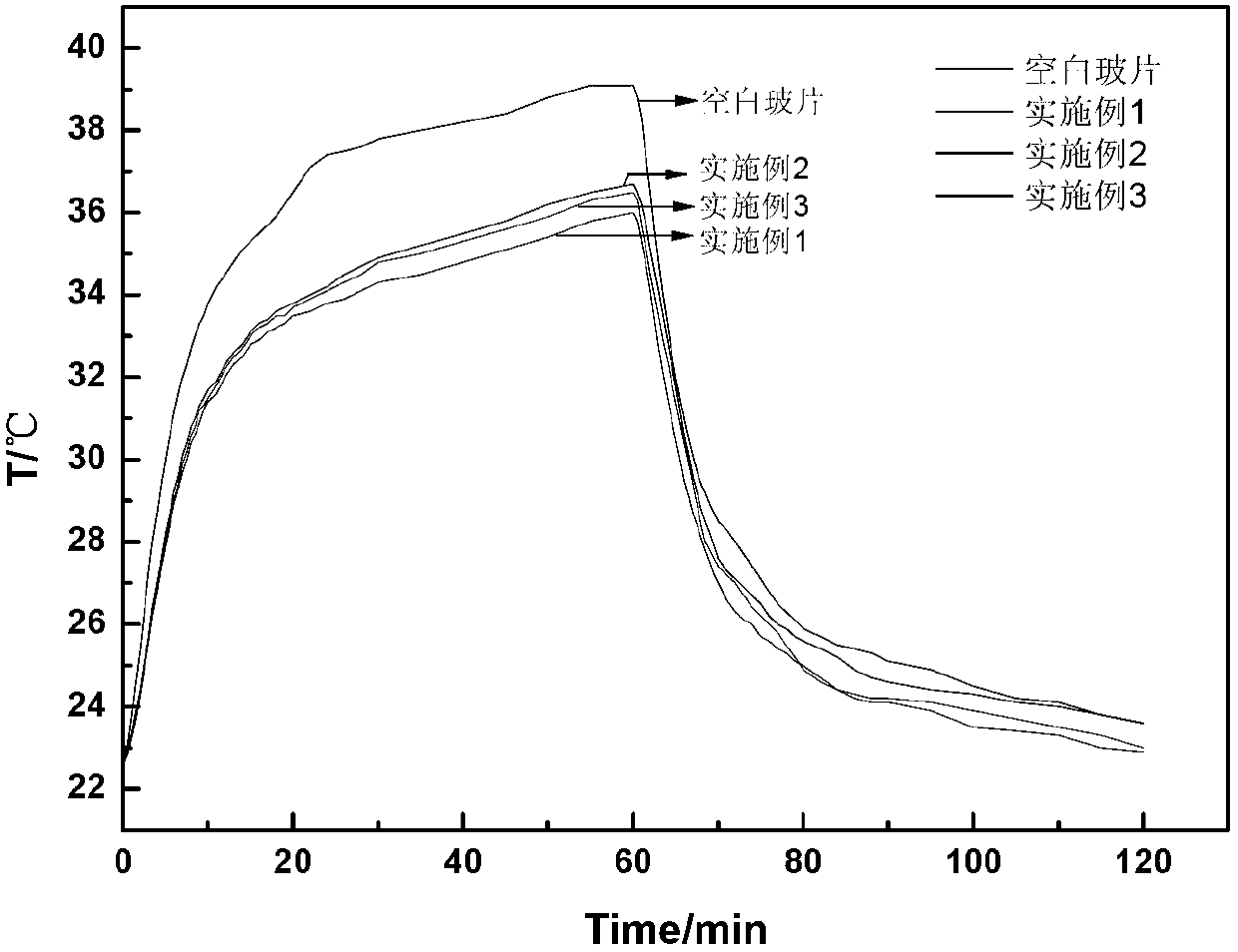

[0039] figure 1 It is a comparison chart of the heat insulation effect of the transparent heat-insulating self-cleaning glass slide prepared in Examples 1, 2, and 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com