Bead edge stitch sewing machine

A sewing machine and edge thread technology, which is applied in the field of sewing machines, can solve problems such as easy skipping and affecting sewing performance, and achieve the effects of stable crochet hooking, reducing vibration, and avoiding friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

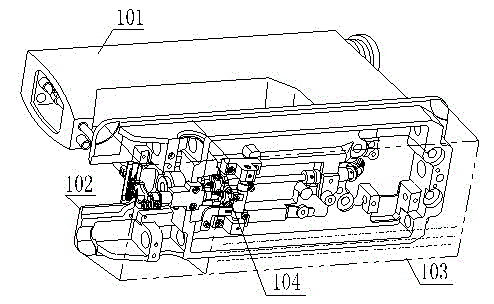

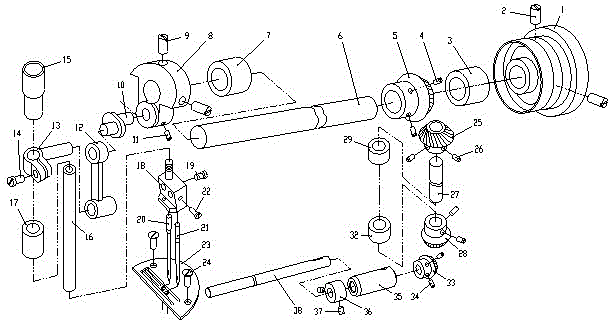

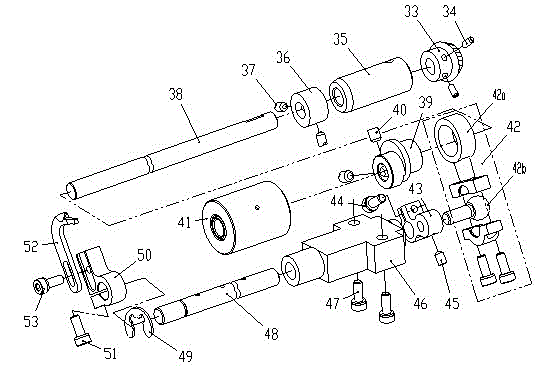

[0067] Such as figure 1 As shown, the bead stitch sewing machine of the present invention includes a machine head 101 and a bottom plate 102. The machine head 101 is arranged on the bottom plate 102; the machine head 101 is provided with a cloth piercing mechanism, which is connected to the left end of the upper shaft 6 and the upper shaft 6. The power drive is realized by the belt pulley 1; the upper shaft 6 drives the lower shaft 38 through two pairs of bevel gears 5, 25, 28, 33 and the vertical shaft 27. The left end of the lower shaft 38 is connected to the expansion ring mechanism 104 that can make the stitches reliably formed. The wire expanding ring mechanism 104 is arranged under the bottom plate 102;

[0068] Such as figure 2 As shown, the piercing mechanism is connected to the left end of the upper shaft 6, and the right end of the upper shaft 6 is fixedly connected to the pulley 1 by two screws 2;

[0069] The pricking mechanism includes a needle bar crank 8, which is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com