Drum machine

A drum machine and gun barrel technology, which is applied to the field of gun barrels and guns, can solve the problems of high cost, low work efficiency and low production efficiency, and achieve the effects of low cost, high work efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

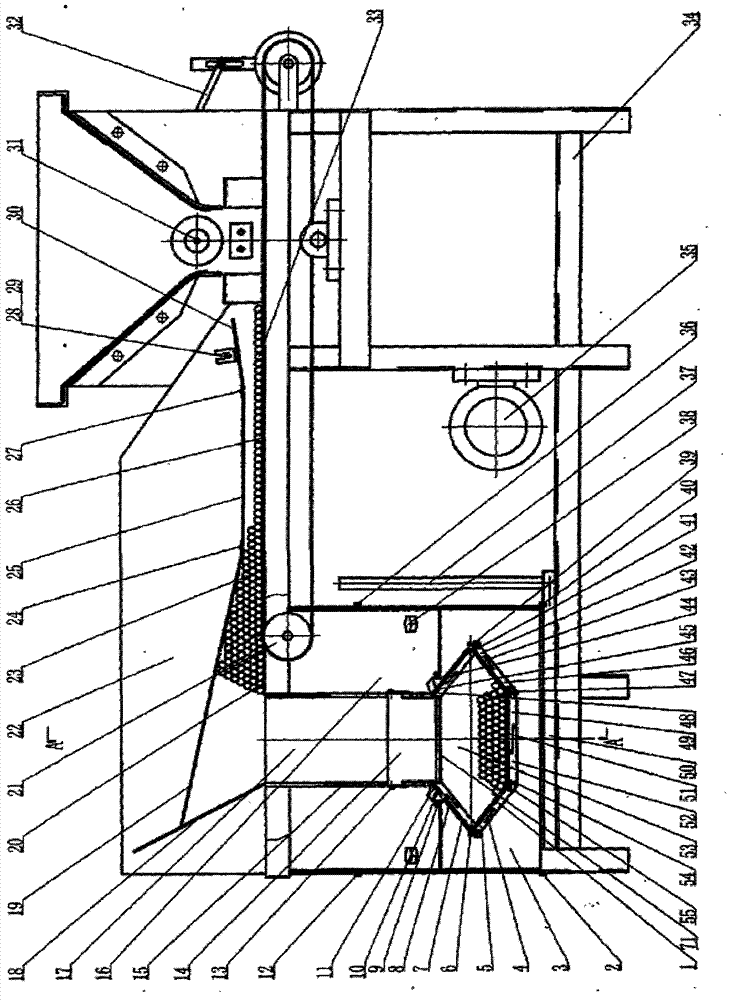

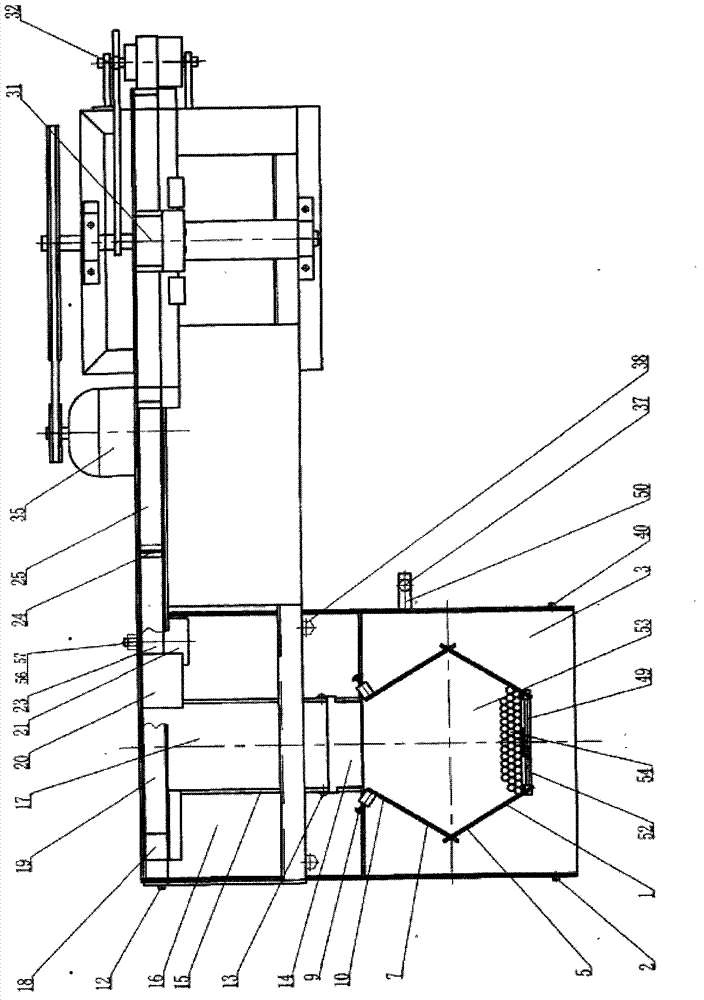

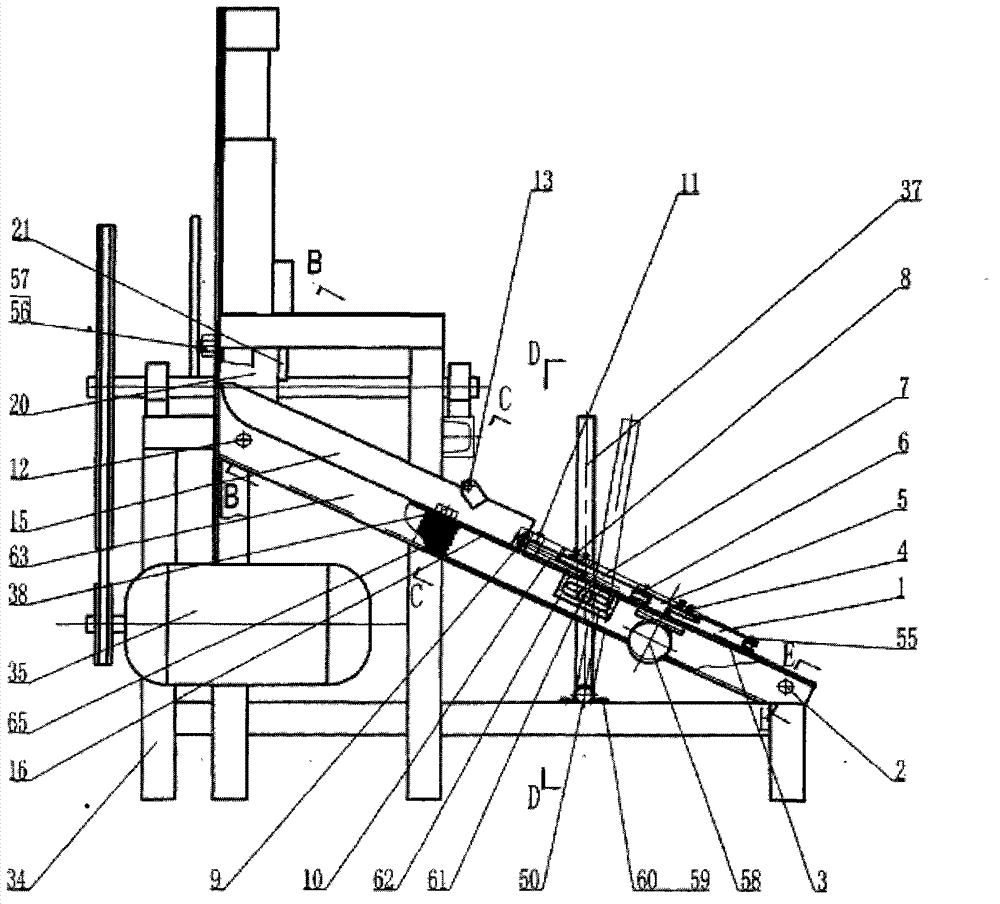

[0017] The preferred embodiment of the present invention is like this, with reference to Figure 1-Figure 8 , the barrel is formed with the existing barrel machine reel and put it into the gun feeding mechanism to flow to the channel between the panel and the fixed platen, flow to the trough to the mold cavity and arrange it into a hexagonal cannon plate, and then tie it with rope around the periphery Tighten and serve. It can also be manually rolled into a barrel and then sent to the channel between the panel of the barrel machine and the fixed platen to flow to the mold cavity and arranged into a hexagonal barrel. Specifically: install the mechanism setting of the present invention on the left side and the top of the frame (34) of the existing gun barrel forming machine, and the conveying gun barrel mechanism (31) has a belt transmission mechanism (32), and a conveyor belt of the belt transmission mechanism (32) (23) panel (26) is installed on the face, panel (26) is follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com