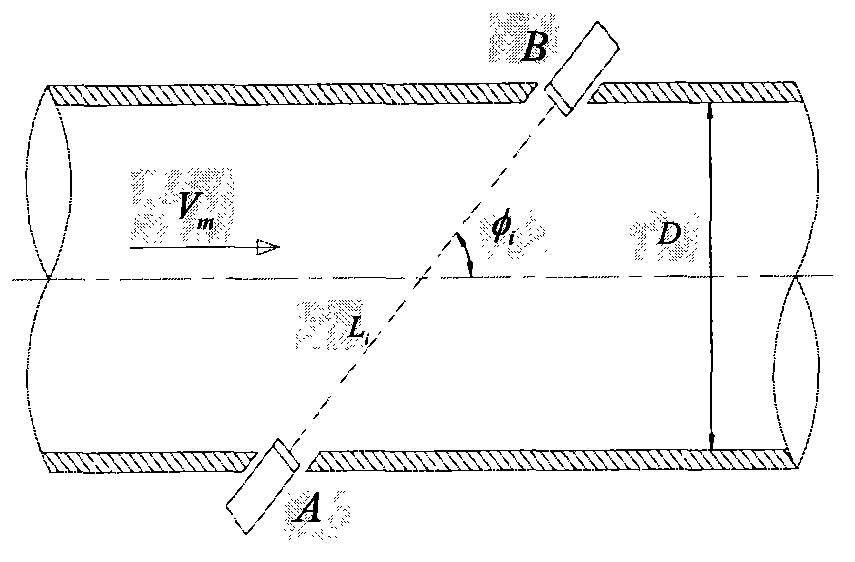

Delay detection calibrating device for ultrasonic flowmeter

A technology of ultrasonic flowmeter and time-delay detection, applied in the direction of test/calibration device, measurement device, measurement flow/mass flow, etc., to achieve the effect of great versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

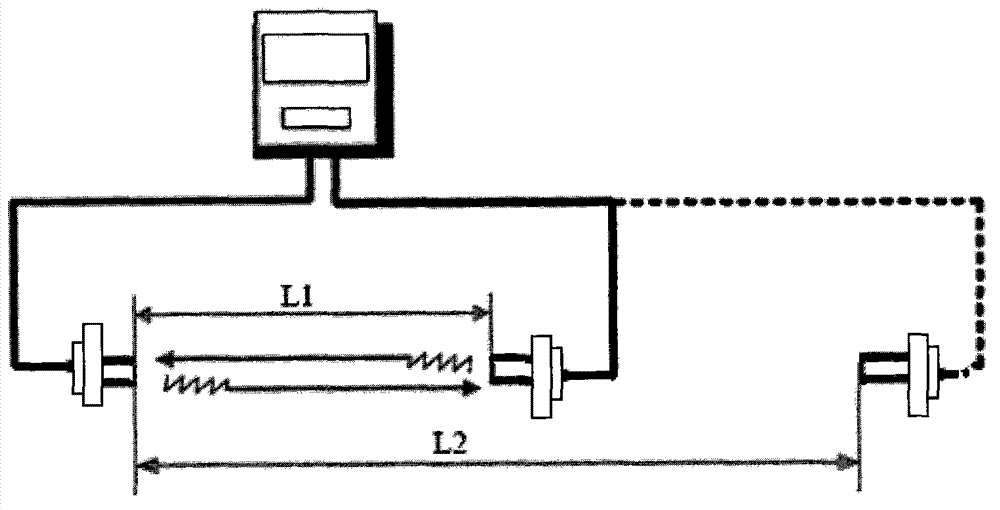

Method used

Image

Examples

Embodiment 1

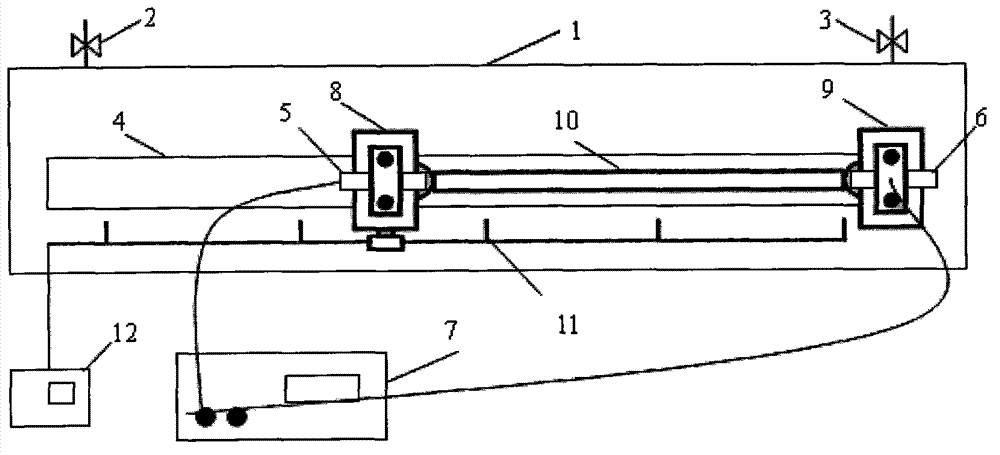

[0042] Such as image 3 The shown device includes a water tank 1, which is an airtight container, preferably the airtight container is made of stainless steel or anti-corrosion, moisture-proof materials, has a predetermined storage space inside, and has a switch with a switch on the water tank 1. The water injection port 2 and the drain port 3 with switch function, the water tank 1 injects liquid through the water injection port 2, when the liquid fills the water tank 1, it will automatically overflow from the position of the drain port 3, the injected liquid can be water or other Liquids that need to be transported through flow pipes in actual industrial production. The liquid is any suitable liquid whose velocity can be measured by an ultrasonic flowmeter.

[0043] Such as image 3 As shown, the water tank 1 is an insulated water tank. It would be better if the temperature can be controlled, which can avoid excessive temperature changes during measurement and affect the ac...

Embodiment 2

[0048] As another embodiment of the present invention, its structure is the same as that in Embodiment 1, so it will not be repeated here. In Embodiment 2, there may be a plurality of slide rail systems arranged in parallel in the water tank. A pair of probe clamping mechanisms and ultrasonic flowmeter probes are set up on the system. Multiple slide rail systems can simultaneously measure multiple pairs of ultrasonic flowmeter probe pairs. When measuring, the ultrasonic probe is positioned first, and a quartz tube with a length of about 10mm is used. The rod clamp is installed between the fixed probe clamping mechanism and the sliding probe clamping mechanism, and the clamping mechanism is tightened and the sliding probe clamping mechanism is fixed on the slide rail; the two probes of the measured flowmeter are placed in the clamping mechanism of the probe clamping mechanism In the plate, attach the end faces of the two probes to the two ends of another quartz rod with a length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com