Method for evaluating damage self-healing capacity of asphalt mortar

An asphalt mortar, self-healing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of expensive test equipment, high operation requirements, and cumbersome evaluation process, and achieves a simple, feasible and easy-to-operate method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

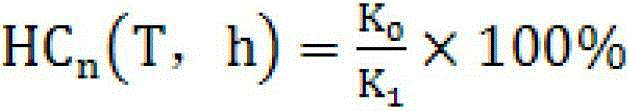

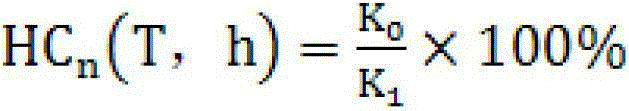

[0029] Taking a cylinder with a diameter of 30 mm and a height of 50 mm as the asphalt mortar to be tested as an example, the self-healing evaluation method includes the following steps:

[0030] (1) Preheat the test piece in a constant temperature box at 40°C for 5 hours; the test piece is an asphalt mortar cylinder with a diameter of 30mm and a height of 50mm, and its preparation method refers to the molding method according to JTJ052-2000 "Highway Engineering The preparation method of asphalt mixture specimens in T0704-1993 Asphalt Mixture Test Regulations is the static pressure method.

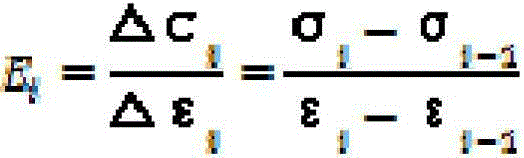

[0031] (2) Set the stretching temperature to 40°C, carry out bidirectional stretching with equal strain rate on the test piece, the stretching speed is 2mm / min, and collect the stress value σ at the initial moment 0 with strain value ε 0 , resulting in the initial tensile damage modulus E 0 , continue to stretch and collect the stress value σ acting on the test piece in real time t and ...

Embodiment 2

[0052] Taking a cylinder with a diameter of 30 mm and a height of 50 mm as the asphalt mortar to be tested as an example, the self-healing evaluation method includes the following steps:

[0053] (1) Preheat the test piece in an incubator at 35° C. for 6 hours; the test piece is the same as that in Example 1.

[0054] (2) Set the stretching temperature to 35°C, carry out bidirectional stretching with equal strain rate on the test piece, the stretching speed is 2mm / min, and collect the stress value σ at the initial moment 0 with strain value ε 0 , resulting in the initial tensile damage modulus E 0 , continue to stretch and collect the stress value σ acting on the test piece in real time t and strain value ε t , until the tensile damage modulus E after t seconds t with E 0 ratio of n 0 When it reaches 0.3, stop stretching;

[0055] (3) Apply a constant pressure of 0.1MPa to both ends of the test piece stretched in step (2) at the same time, the test piece will self-heal,...

Embodiment 3

[0059] Taking a cylinder with a diameter of 30 mm and a height of 50 mm as the asphalt mortar to be tested as an example, the self-healing evaluation method includes the following steps:

[0060] (1) Preheat the test piece in an incubator at 50° C. for 3 hours; the test piece is the same as that in Example 1.

[0061] (2) Set the stretching temperature to 50°C, carry out bidirectional stretching with equal strain rate on the test piece, the stretching speed is 2 mm / min, and collect the stress value σ at the initial moment 0 with strain value ε 0 , resulting in the initial tensile damage modulus E 0 , continue to stretch and collect the stress value σ acting on the test piece in real time t and strain value ε t , until the tensile damage modulus E after t seconds t with E 0 ratio of n 0 When it reaches 0.6, stop stretching;

[0062] (3) Apply a constant pressure of 0.1MPa to both ends of the test piece stretched in step (2) at the same time, the test piece will self-heal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com