Intelligent composite material reinforcing rib for building field

A technology of composite materials and ribs, applied in measuring devices, thermometers with physical/chemical changes, instruments, etc., can solve problems such as late start, and achieve the effects of avoiding accidents, strong corrosion resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

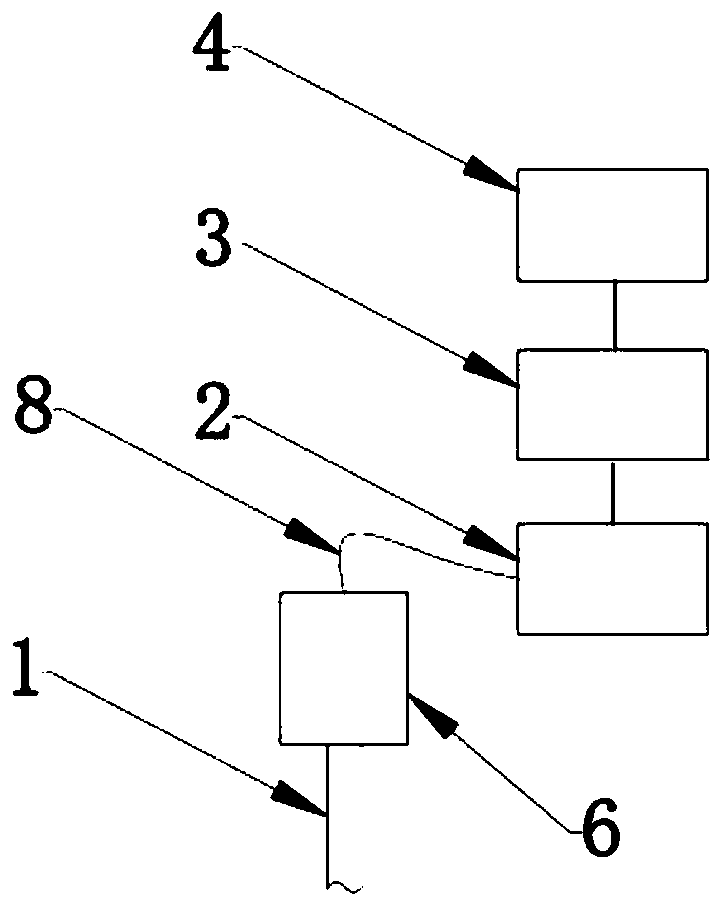

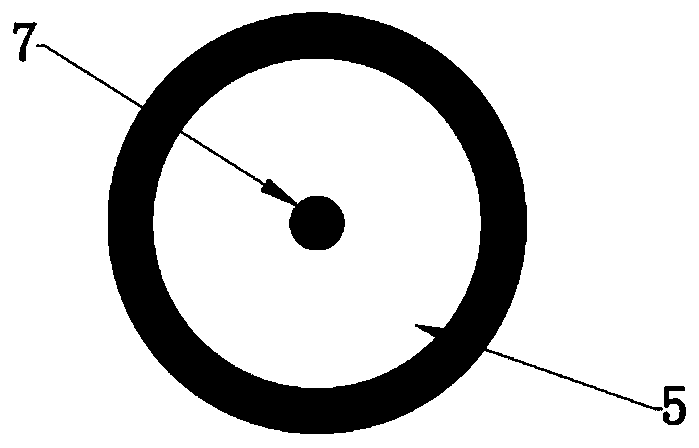

[0028] Such as figure 1 and figure 2 Said, a kind of intelligent composite material reinforcing bar for construction field, it comprises composite material reinforcing bar 1 connected in sequence, measurement and control system 2, data processing system 3 and alarm system 4; Described composite material reinforcing bar 1 comprises composite material rod body 5. The measurement and control optical fiber unit 7 located inside the composite material rod body 5; the measurement and control optical fiber unit 7 in the composite material reinforcing rib 1 and the measurement and control system 2 realize the transmission of measurement and control signals through the optical fiber 8;

[0029] The composite rod body 5 and the measurement and control optical fiber unit 7 are integrally formed through a pultrusion process;

[0030] The outer surface of the composite rod body 5 is pressed with indentations. The depth of indentation is not less than 0.3mm, and the maximum interval of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com