Imaging optical lens group

A technology of imaging optics and lens groups, applied in optics, optical components, instruments, etc., can solve problems such as unsatisfactory photography lens modules, and achieve the effects of reducing sensitivity, reducing volume, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

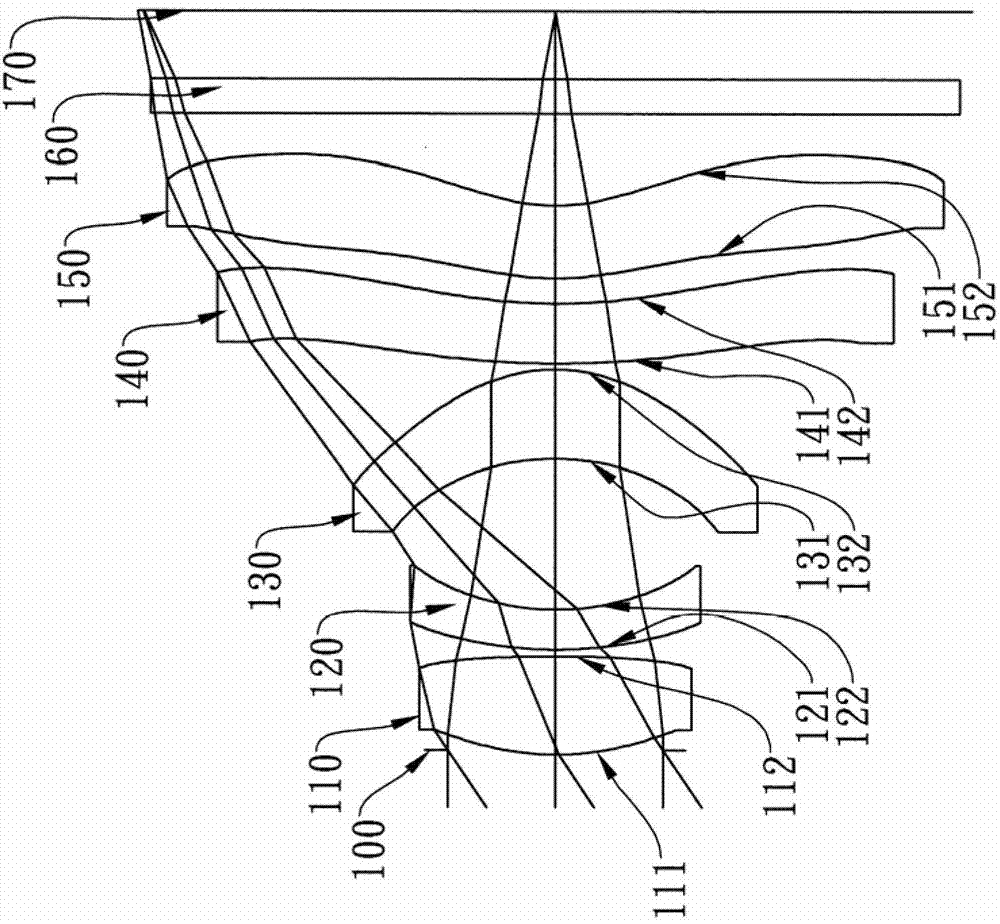

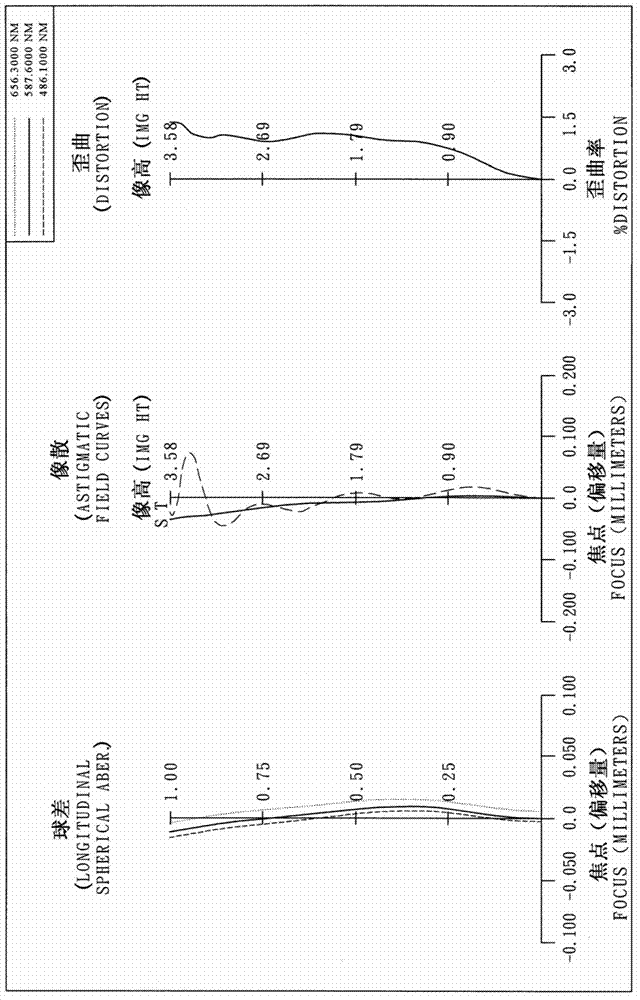

[0094] Please refer to the schematic diagram of the optical system of the first embodiment of the present invention Figure 1A , for the aberration curve of the first embodiment, please refer to Figure 1B . The imaging optical lens group of the first embodiment is mainly composed of five lenses, which sequentially include from the object side to the image side:

[0095] A first lens 110 with positive refractive power, its object-side surface 111 and image-side surface 112 are convex, its material is glass, the object-side surface 111 and image-side surface 112 of the first lens 110 are both aspherical ;

[0096] A second lens 120 with negative refractive power, its object side surface 121 is convex and image side surface 122 is concave, its material is plastic, the object side surface 121 and image side surface 122 of the second lens 120 are both aspherical ;

[0097] A third lens 130 with positive refractive power, its object side surface 131 is concave and image side sur...

no. 2 example

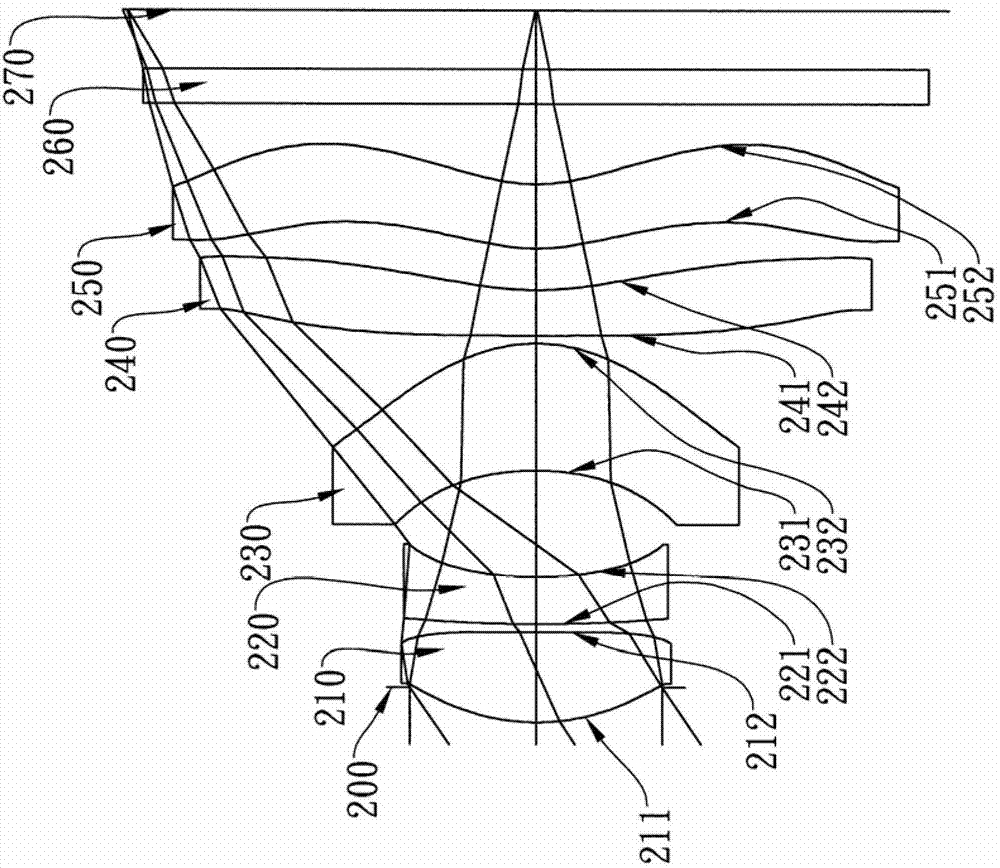

[0125] Please refer to the schematic diagram of the optical system of the second embodiment of the present invention Figure 2A , for the aberration curve of the second embodiment, please refer to Figure 2B . The imaging optical lens group of the second embodiment is mainly composed of five lenses, which sequentially include from the object side to the image side:

[0126] A first lens 210 with positive refractive power, its object side surface 211 is convex and image side surface 212 is concave, its material is plastic, the object side surface 211 and image side surface 212 of the first lens 210 are both aspherical ;

[0127] A second lens 220 with negative refractive power, its object side surface 221 is convex and image side surface 222 is concave, its material is plastic, the object side surface 221 and image side surface 222 of the second lens 220 are both aspherical ;

[0128] A third lens 230 with positive refractive power, its object side surface 231 is concave and ...

no. 3 example

[0150] Please refer to the schematic diagram of the optical system of the third embodiment of the present invention Figure 3A , for the aberration curve of the third embodiment, please refer to Figure 3B . The imaging optical lens group of the third embodiment is mainly composed of five lenses, which sequentially include from the object side to the image side:

[0151] A first lens 310 with positive refractive power, its object side surface 311 is convex and image side surface 312 is concave, its material is plastic, the object side surface 311 and image side surface 312 of the first lens 310 are both aspherical ;

[0152] A second lens 320 with negative refractive power, its object side surface 321 is convex and image side surface 322 is concave, its material is plastic, the object side surface 321 and image side surface 322 of the second lens 320 are both aspherical ;

[0153] A third lens 330 with positive refractive power, its object side surface 331 is concave and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com