Method for producing high-strength steel sheet

A technology of high-strength steel plate and manufacturing method, which can be applied to manufacturing tools, coatings, furnace types, etc., and can solve the problems of difficulty in utilizing low-temperature transformation structure and limited improvement of steel plate workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

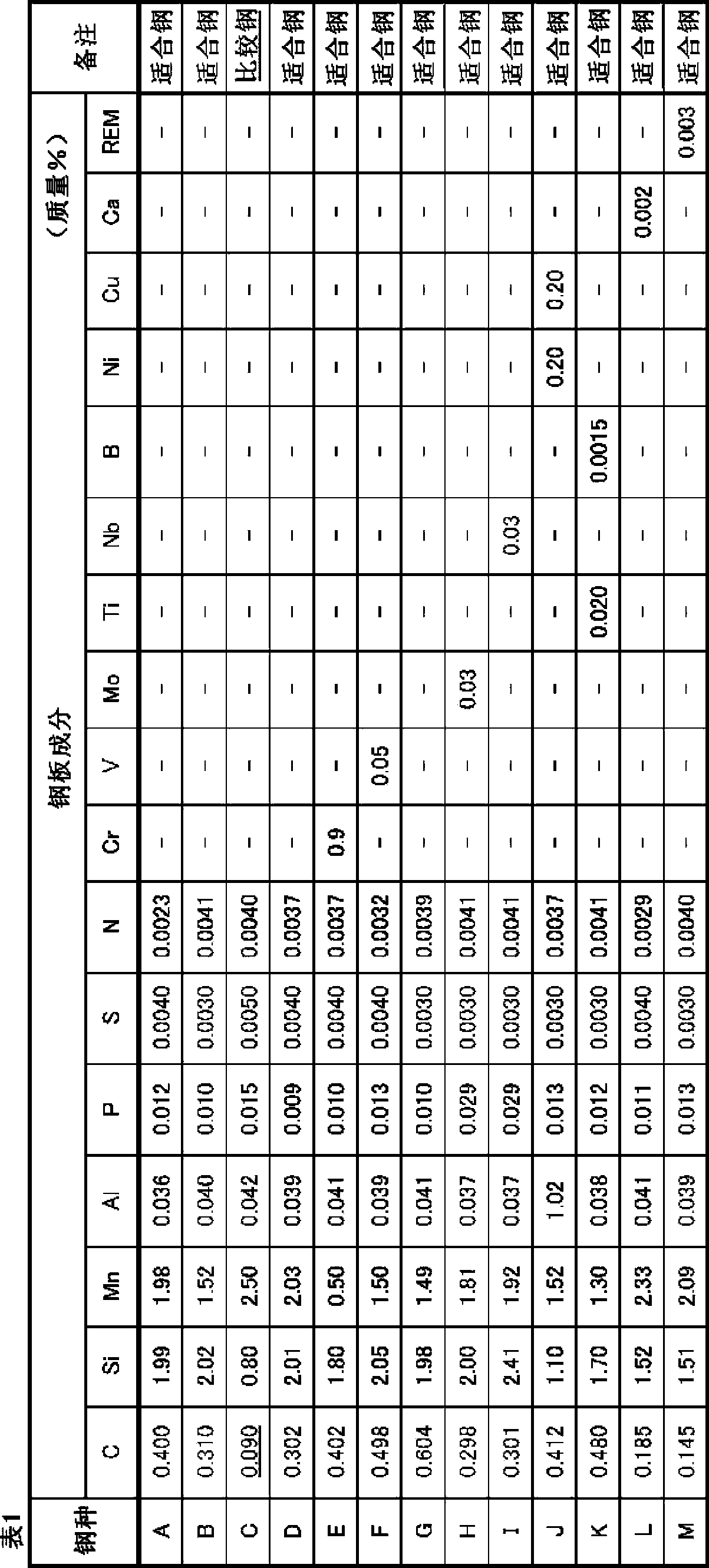

[0138]The present invention is further described in detail through examples below, but the present invention is not limited to the following examples. In addition, even if the structure is changed within the scope of the present invention, the effects of the present invention will of course be found.

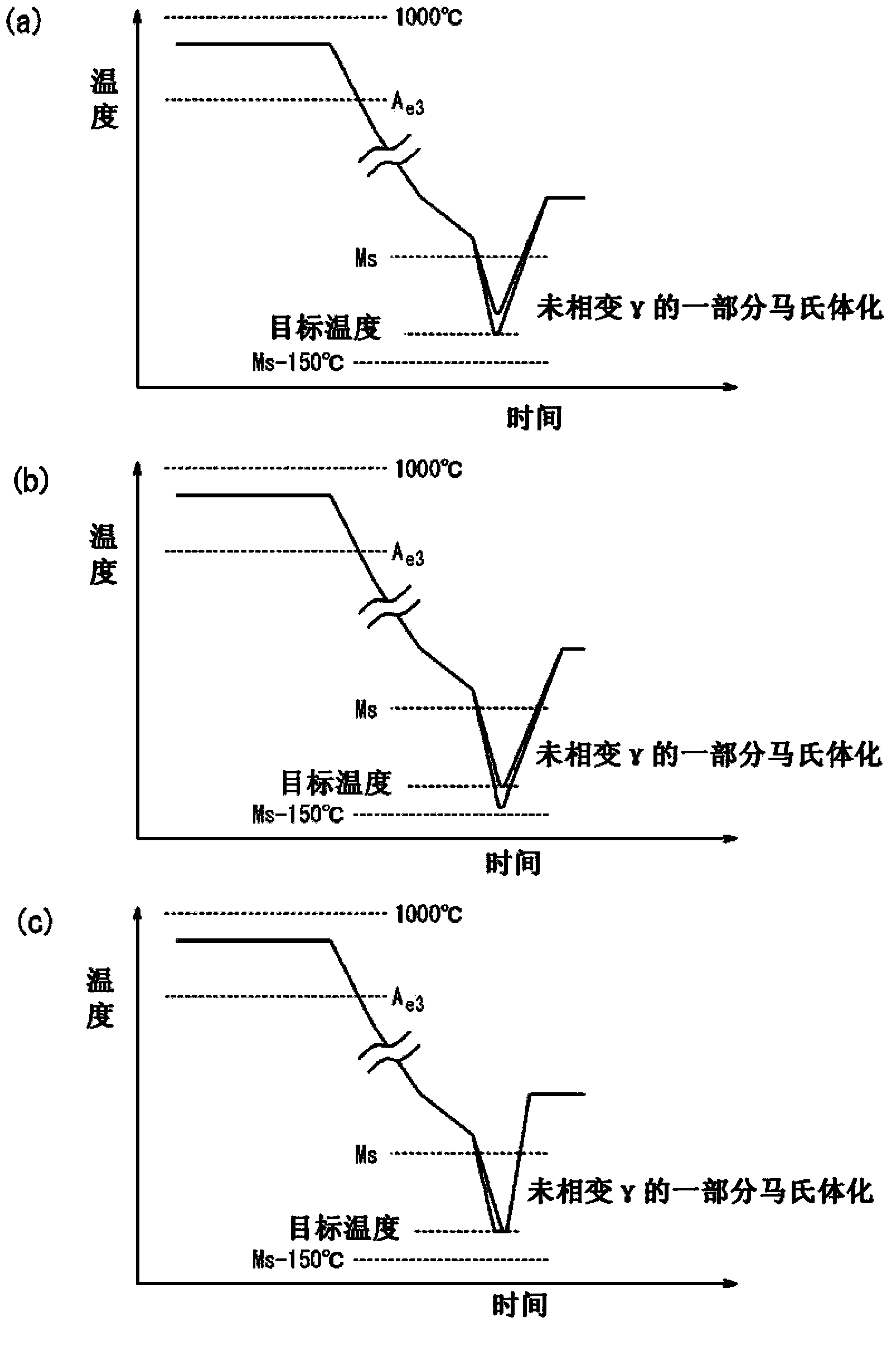

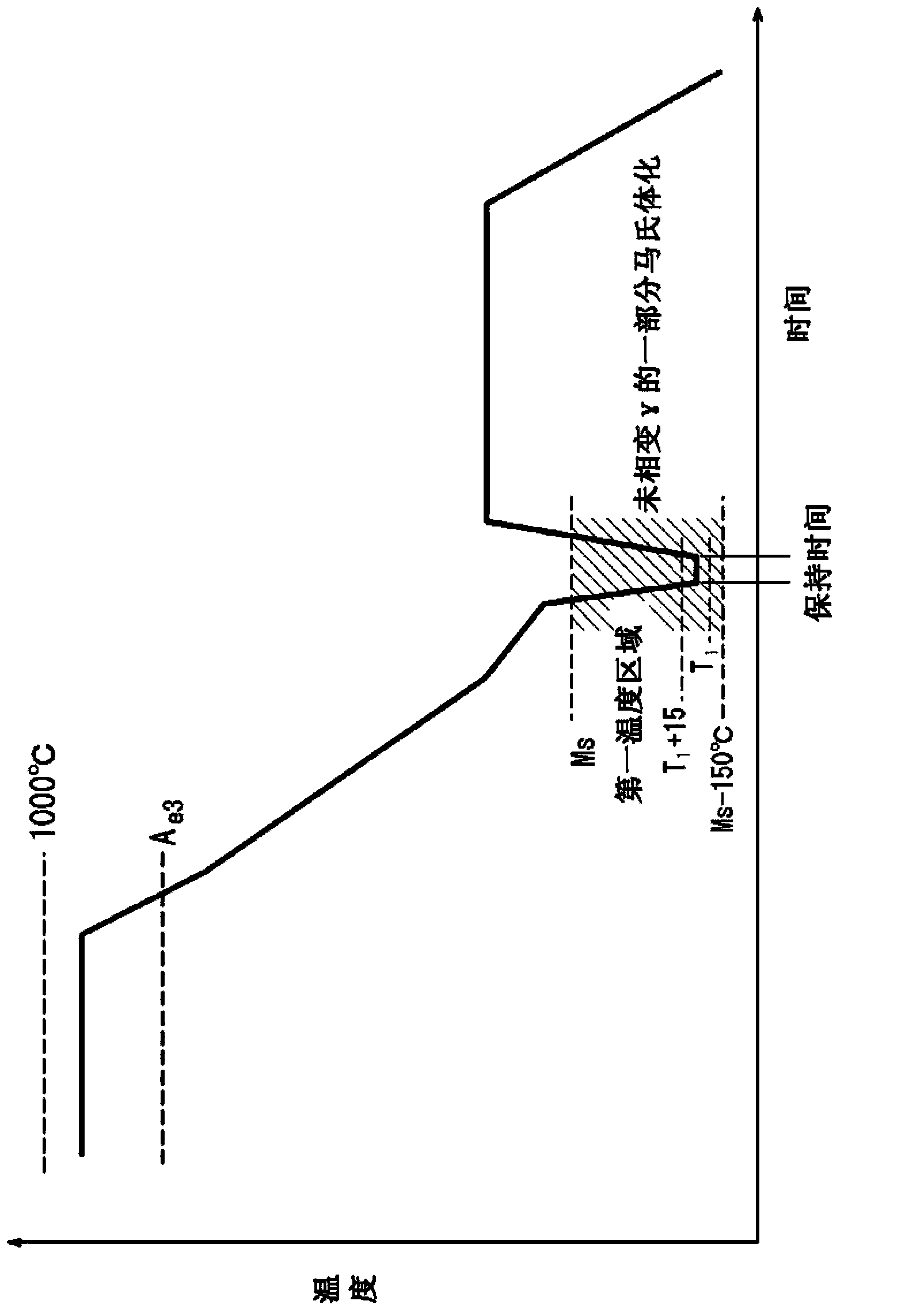

[0139] The slab obtained by melting the steel with the composition shown in Table 1 was heated to 1200°C, and the hot-rolled steel sheet obtained by the final hot rolling at 870°C was coiled at 650°C, and then the hot-rolled steel sheet was acid-treated. After washing, cold rolling was performed at a rolling rate (rolling rate) of 65% to obtain a cold-rolled steel sheet with a thickness of 1.2 mm. The obtained cold-rolled steel sheets were heat-treated under the conditions shown in Table 2.

[0140] The heat treatment temperature (annealing treatment temperature) was set to the temperature in the austenite single-phase region or (austenite + ferrite) two-phase region except for...

Embodiment 2)

[0163] Furthermore, heat treatment was performed under the conditions shown in Table 4 using Steel Type A in Table 1. Table 5 shows the results of investigations on the mechanical characteristics and variations thereof in each case. In terms of the deviation of the mechanical properties of the steel plate, the material cut from the rolling direction length: 1000mm to the rolling direction length 40mm×width 250mm is uniformly distributed in the width direction from the two most edge parts toward the center part of the steel plate in the evaluation part Take 20 pieces in the same way, process them into JIS No. 5 test pieces, and then carry out the tensile test. The cases where the standard deviation σ of the tensile strength and T.EL were 10 MPa or less and 2.0% or less were judged to be good.

[0164] [Table 4]

[0165]

[0166] [table 5]

[0167]

[0168] As shown in Table 5, it can be seen that the tensile strength and standard deviation σ of T.EL of samples No. 18 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com