Rolling bearing device having a hydraulic damping device

A technology for rolling bearings and equipment, which is applied to rolling contact bearings, bearings for rotational motion, bearings, etc., and can solve problems such as response performance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

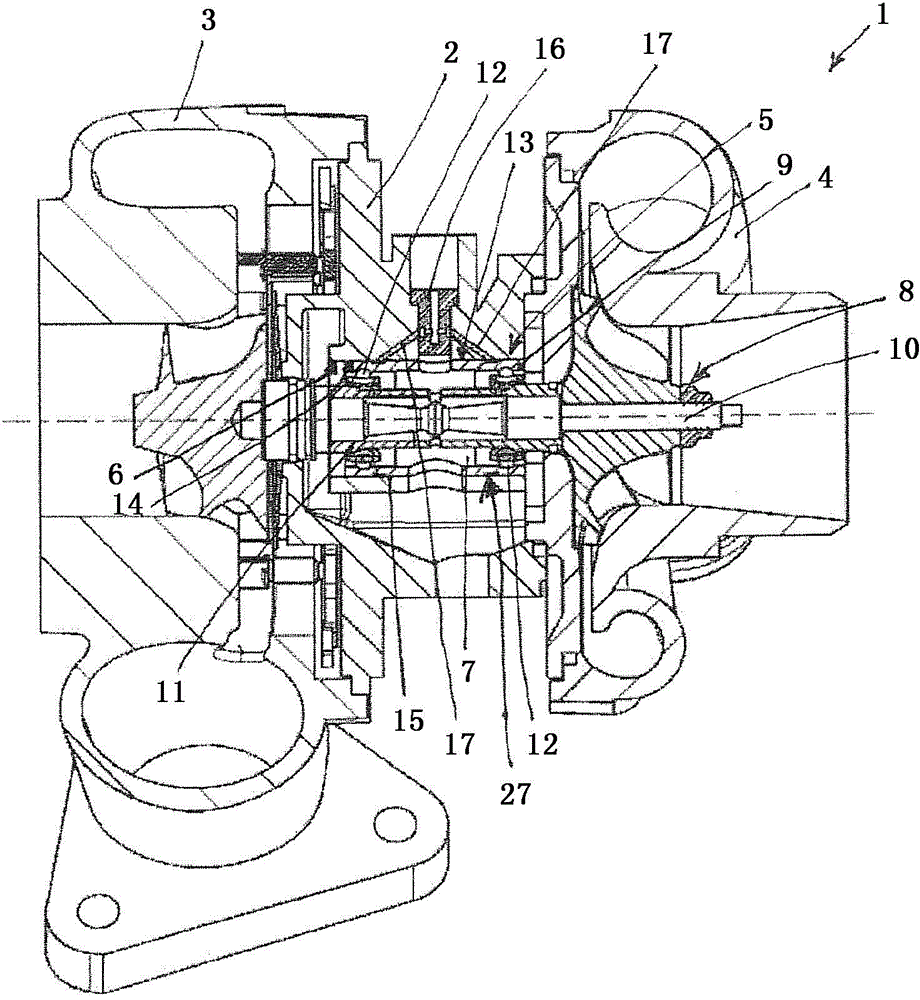

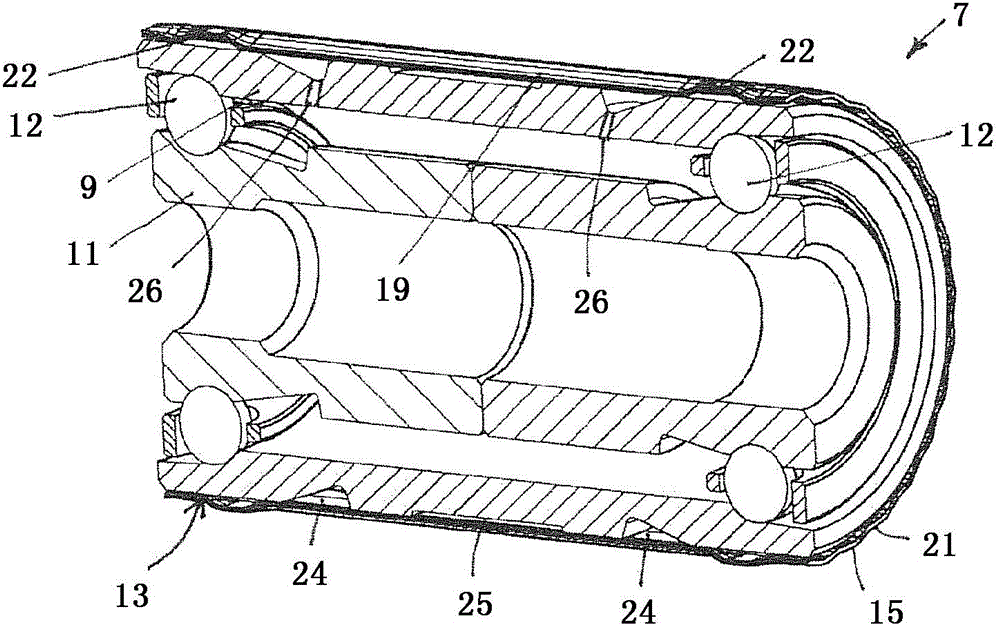

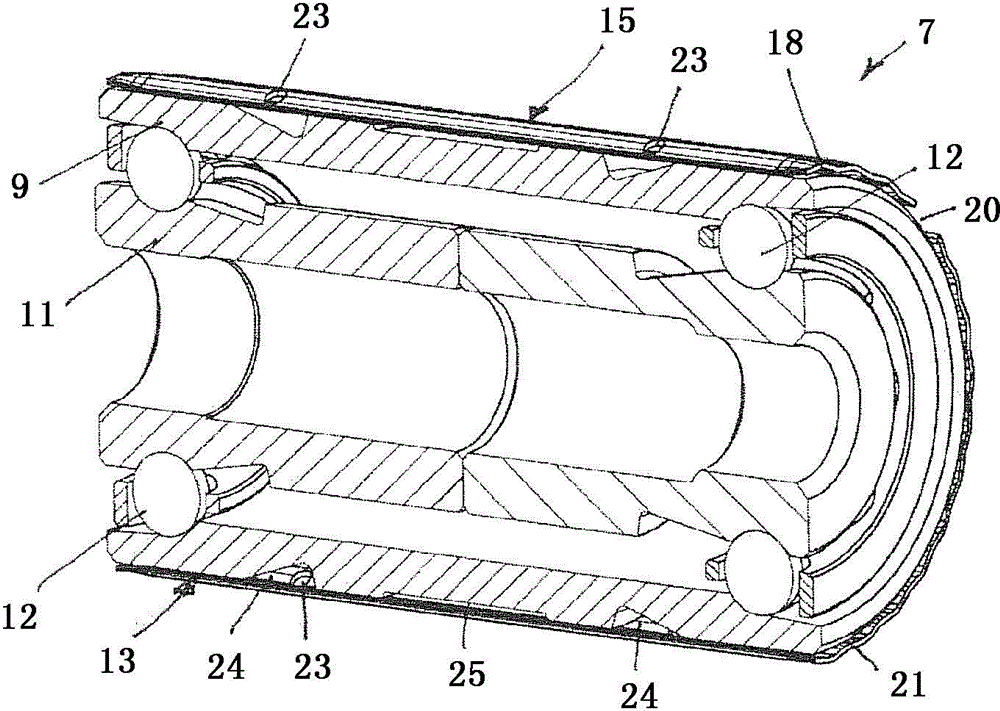

[0018] figure 1 A turbocharger 1 is shown with a housing component 2 , a compressor housing 3 and a turbine housing 4 , the housing component 2 acting as a bearing housing. The housing component 2 comprises a rolling bearing arrangement 5 with a rolling bearing 7 for rotationally mounting a rotor assembly 8 , which is accommodated radially elastically in a bearing bore 6 . To this end, the inner ring 11 of the rolling bearing 7 that can be twisted on the outer ring 9 by means of two rows of rolling elements 12 accommodates the rotor 10 of the rotor assembly, and the outer ring 9 is arranged on the outer periphery 13 of the outer ring 9 with the bearing hole The bushing 15 between the inner periphery 14 of the housing member 2 is accommodated radially elastically.

[0019] The rolling bearing arrangement 5 is supplied with hydraulic fluid via the throttle valve 16 and the fluid bore 17 , which is pressurized via folds of the bushing 15 which are not visible in this illustratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com