Thick plate rolling method

A technology of forming rolling and rolling process, applied in the direction of metal rolling, contour control, etc., can solve the problems of increased production cost and complicated process, and achieve the effect of increasing the yield and improving the planar shape of the steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

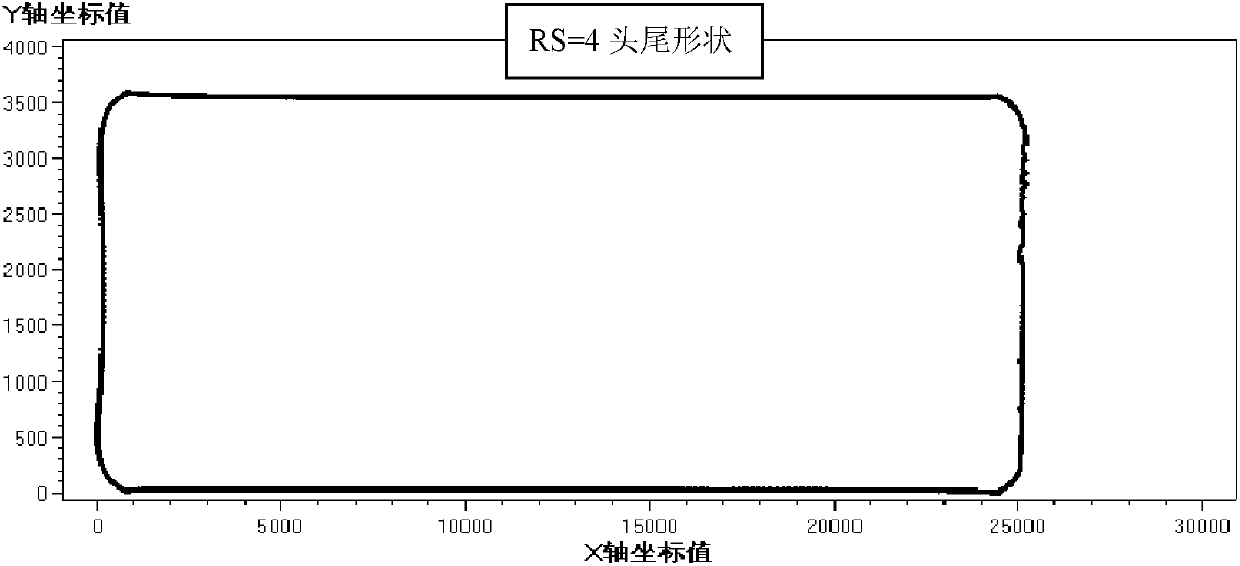

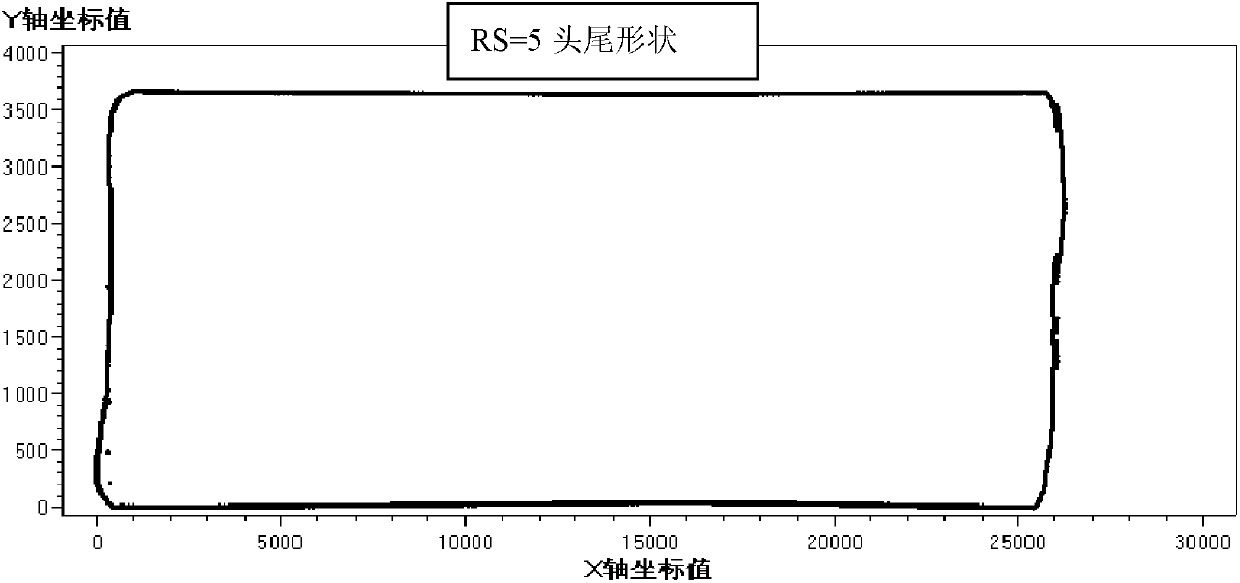

Image

Examples

Embodiment 1

[0052] The initial size of the slab: thickness 297mm, width 1700mm, length 2970mm.

[0053] Target size of rolled steel plate: thickness 20.12mm, width 4307mm, length 17304mm.

[0054] Transfer steel code RS=5, use RS=5 for rolling, the width ratio is 1.45, the slab size during the rolling process is: 1700mm+10mm=1710mm.

[0055] Forming MAS depth: -1.5mm.

[0056] Widened MAS depth: -4.5mm.

[0057] Before the slab comes to the thick plate rolling mill, it is first rotated 90° for the first time. After the rotation is completed, it is formed and rolled, and the formed MAS rolling is performed in the last pass of the formed rolling (the depth of the formed MAS is -1.5mm); the formed MAS After the rolling is completed, the slab is rotated for the second time. After the rotation is completed, the widening rolling is carried out, and the slab is rolled into the 4307mm width size required by the customer. The widening MAS rolling (widening MAS rolling) is carried out in the last...

Embodiment 2

[0061] The initial size of the slab: thickness 218mm, width 1300mm, length 2670mm.

[0062] Target size of rolled steel plate: thickness 10.11mm, width 3907mm, length 19156mm.

[0063] Transfer steel code RS=5, use RS=5 for rolling, the width ratio is 1.46, the slab size during the rolling process is: 1300mm+15mm=1315mm.

[0064] Forming MAS depth: -1.6mm.

[0065] Widened MAS depth: -3.5mm.

[0066] Before the slab comes to the thick plate rolling mill, it is first rotated 90° for the first time. After the rotation is completed, the forming rolling is carried out, and the forming MAS rolling is performed in the last pass of the forming rolling (forming MAS depth-1.6mm); the forming MAS After the rolling is completed, the slab is rotated for the second time. After the rotation is completed, the widening rolling is carried out, and the slab is rolled into the width size of 3907mm required by the customer. The widening MAS rolling (widening MAS rolling) is carried out in the l...

Embodiment 3

[0070] The initial size of the slab: thickness 297mm, width 1700mm, length 2670mm.

[0071] Rolled steel plate target size: thickness 18.12mm, width 3217mm, length 23126mm.

[0072] Transfer steel code RS=5, use RS=5 for rolling, the width ratio is 1.20, the slab size during the rolling process is: 1700mm+10mm=1710mm.

[0073] Forming MAS depth: -1.0mm.

[0074] Widened MAS depth: -6.5mm.

[0075] Before the slab comes to the thick plate rolling mill, it is first rotated 90° for the first time. After the rotation is completed, the forming rolling is performed, and the forming MAS rolling is performed in the last pass of the forming rolling (forming MAS depth -1.0mm); the forming MAS After the rolling is completed, the slab is rotated for the second time. After the rotation is completed, the widening rolling is carried out, and the slab is rolled into the width size of 3217mm required by the customer. The widening MAS rolling (widening MAS rolling) is carried out in the last ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com