Method and device for rapidly and accurately detecting and controlling baking temperature of ladle

A technology of baking temperature and ladle, which is applied in the direction of measuring device, configuration of indicating equipment/measuring equipment, radiation pyrometry, etc. The structure is compact, simple and reasonable, and the effect of improving the temperature measurement environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

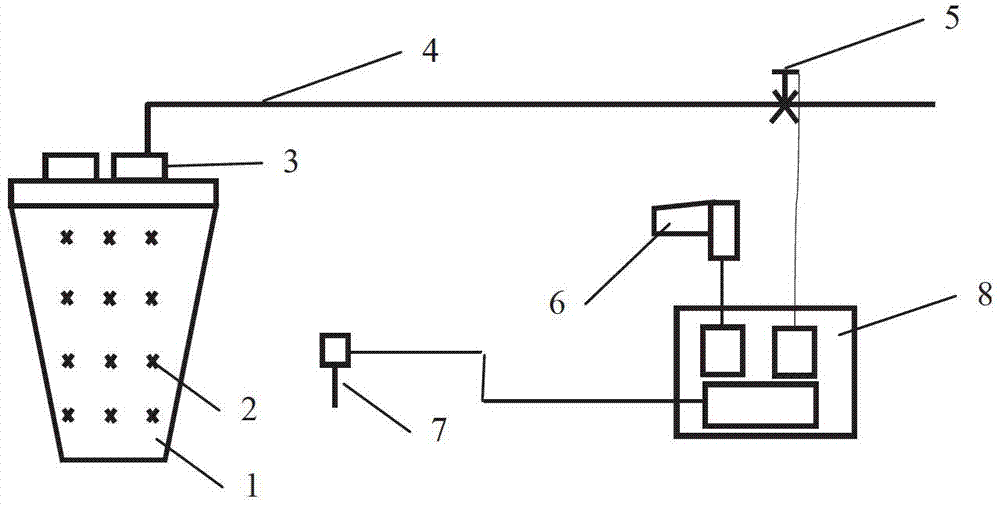

[0022] See figure 1 , is a structural schematic diagram of an embodiment of a device for quickly and accurately controlling the baking temperature of a ladle in the present invention, including PLC8, infrared thermometer 6, hot wire anemometer 7 and solenoid valve 8, infrared thermometer 6, hot wire anemometer 7 and The solenoid valves 5 are connected to the PLC8 respectively, and the solenoid valves 5 are provided on the fuel pipeline 4 . PLC8 model is Siemens S7-200.

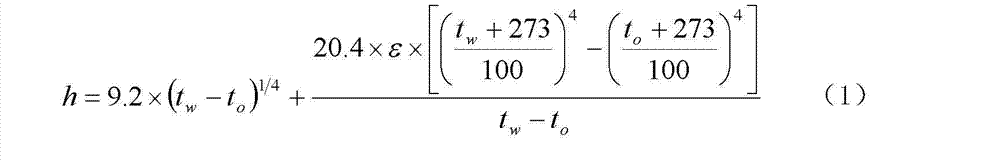

[0023] The present invention provides a method for quickly and accurately controlling the baking temperature of a steel ladle. The infrared thermometer 6 is used to measure the temperature values of multiple measuring points 2 on the outer surface of the steel ladle 1, and the temperature of each point on the inner surface of the steel ladle is calculated by implanting a PLC he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com