Intelligent warehouse robot with function of self adaption of coordinate position

A technology of intelligent warehousing and coordinate position, which is applied in the direction of storage devices, object stacking, and object destacking, etc., which can solve the problem of affecting the stacking accuracy, low precision, and inability to accurately stack goods and goods to be stacked in intelligent warehousing and other problems, to achieve the effect of convenient stacking or extraction operation, high positioning accuracy and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

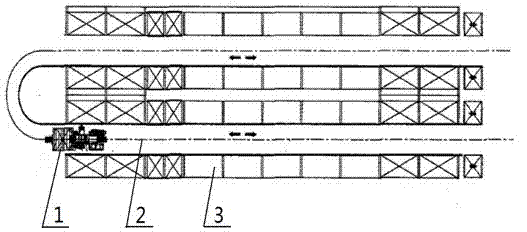

[0032] see figure 1 A schematic diagram of the overall effect of a preferred embodiment of an intelligent storage robot with adaptive coordinate position. In this embodiment, the intelligent storage stacking device 1 in the storage is located between four rows of storage shelves 3, and the space between the storage shelves 3 The guiding aisle 2 includes two aisles and a semicircular transition connecting aisle connecting adjacent straight aisles.

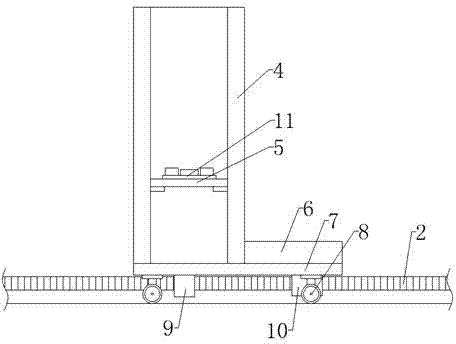

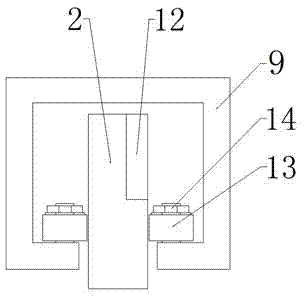

[0033] And for intelligent warehouse stacking device 1 in this embodiment, its specific structure sees figure 2 In this embodiment, a control box 6 and a lifting track 4 are installed side by side on the base frame 7 of the intelligent storage and stacking device 1. The lifting track 4 is a symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com