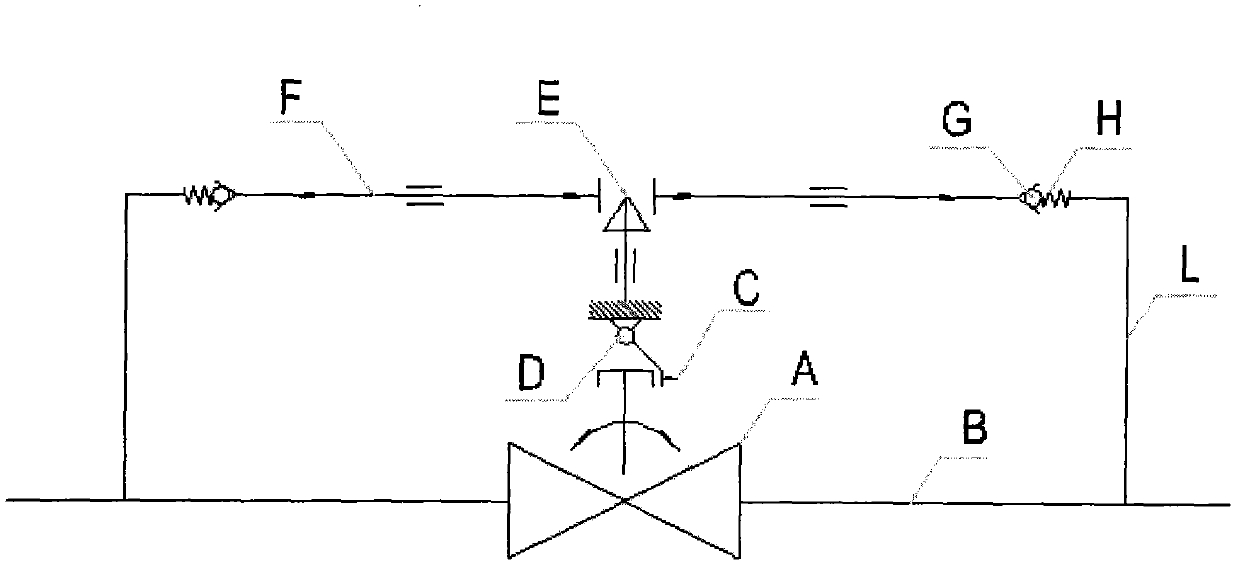

Inward depressurizing high pressure soft sealing ball valve

A soft-sealing, high-pressure technology that is applied to valve details, valve devices, valve housing structures, etc., can solve the problem of large opening and closing torque of the valve seat, and achieve the effects of small friction, less wear and reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

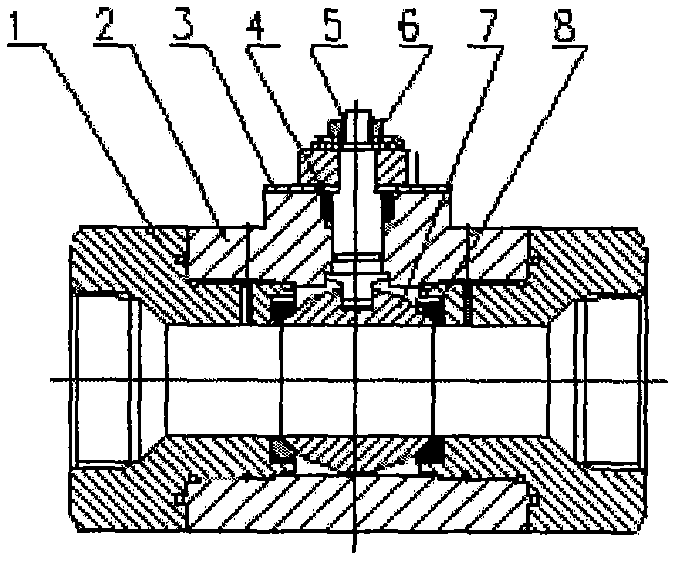

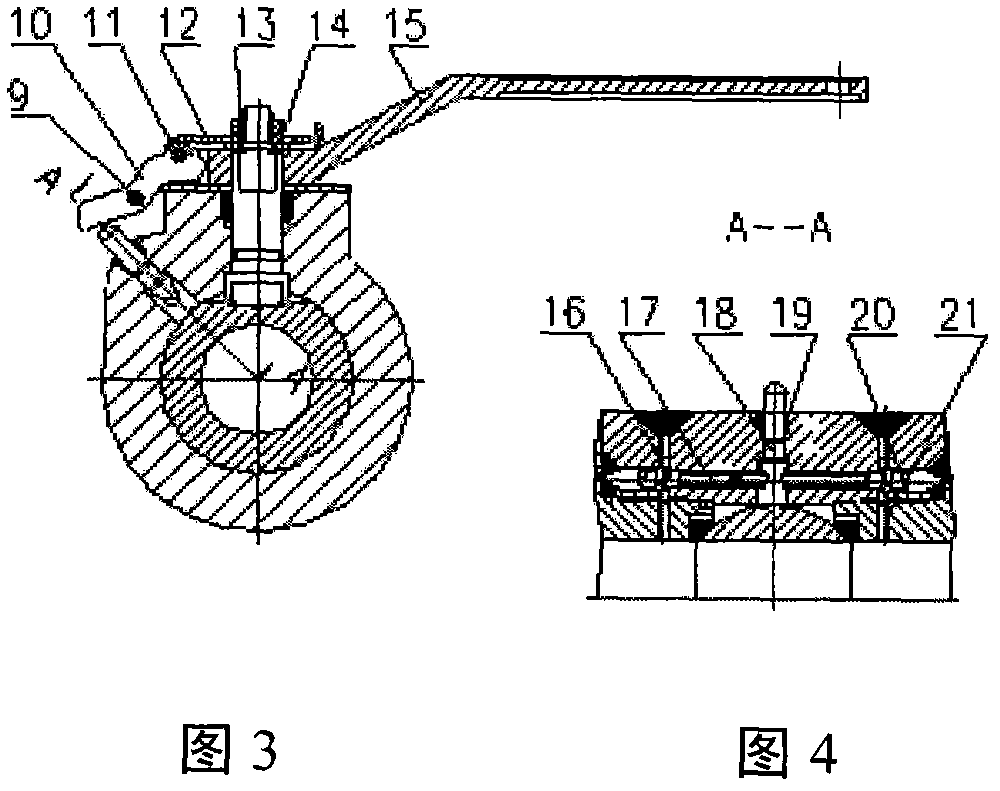

[0030] Such as figure 2 , image 3 with Figure 4 As shown, the flange in the middle hole of the valve is provided with screw holes for connecting the support plate 3 or the operator, and the support plate 3 is connected with the pendulum positioning link 10 through the positioning pin 9 . The pendulum positioning link 10 can swing along the axis of the positioning pin 9.

Embodiment 3

[0032] Such as figure 2 , image 3 with Figure 4 As shown, the valve is equipped with a locking mechanism, the connecting end of the pendulum positioning link 10 and the pressure plate handle 12 is provided with a positioning part, and the handle 15 and the outer edge of the valve stem sleeve are provided with two positioning grooves arranged at 90 degrees. The concavo-convex of the positioning part of the pendulum positioning connecting rod 10 matches, and the valve opening and pipe positions can be locked.

Embodiment 4

[0034] Such as figure 2 , image 3 with Figure 4 As shown, the two ends of the bypass are respectively provided with check valves, and the plunger 18 moves axially through the downward pressure of the pendulum positioning connecting rod 10, and the inclined wedge mechanism of the plunger 18 drives the slide rod 17 to translate, pushing away the steel ball 16, the spring 20 Open the check valve, and the internal pressure relief system is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com