Device, system and method for repairing underground pipeline of trenchless pneumatic cracking pipe

A technology of pneumatic cracking pipes and underground pipes, which is applied in the sewer pipe system, waterway system, pipe laying and maintenance, etc., to reduce the amount of excavation, save costs and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

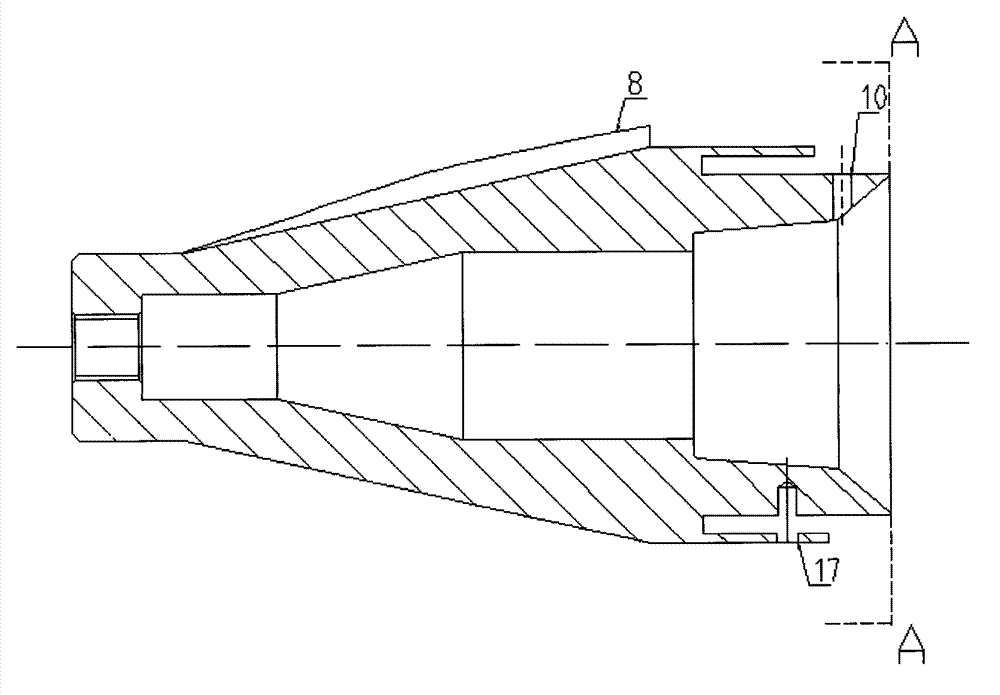

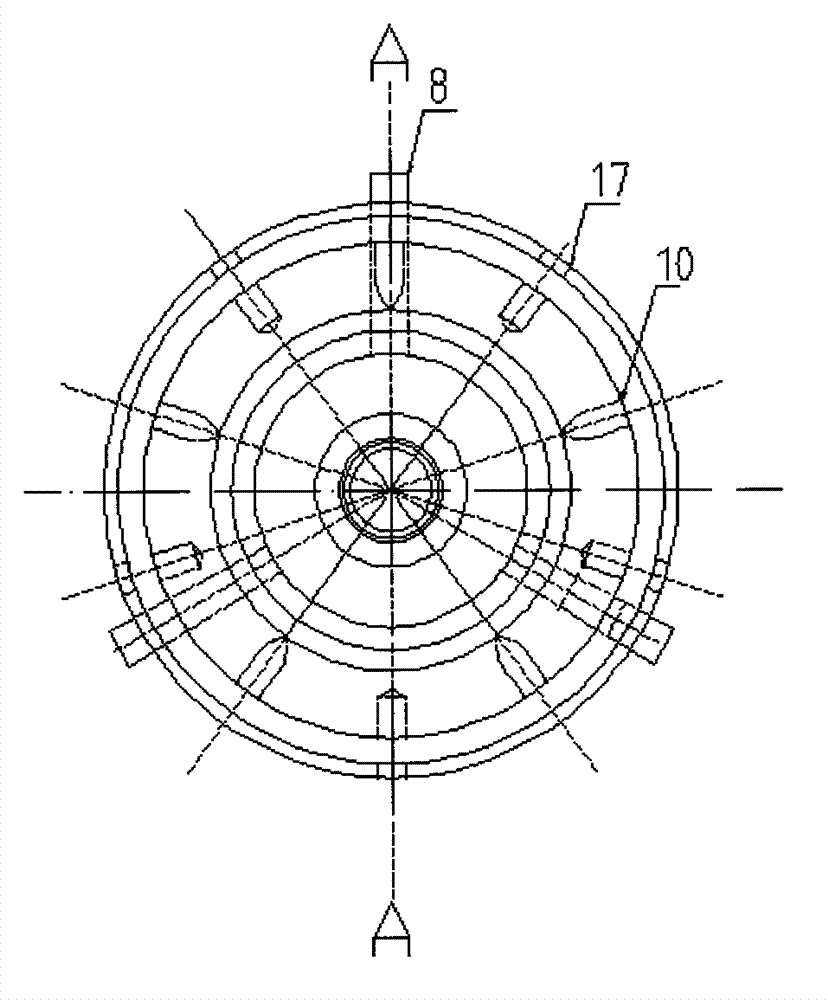

[0052] The first embodiment of the present invention proposes a device for repairing underground pipelines with non-excavation pneumatic cracked pipes, the structure of which is as follows Figure 2 ~ Figure 6 Shown, comprise split pipe head 16, and this split pipe head 16 is provided with conical head and a tail portion that is used to connect replacement pipe 13, and has a through hole; This through hole center line and described tapered head center line Coincident, the front columnar through hole is used to install the front conversion joint 6, and the tail tapered through hole is used to connect the pipe rammer 11.

[0053] Such as Figure 4 As shown, the front adapter 6 is inserted into the opening, and is connected to one end of the regulator 15 through a connecting pin 7 ; and the other end of the regulator 15 is connected to the rear adapter 9 . refer to figure 1 as shown.

[0054] Such as Figure 4 As shown, the rear conversion joint 9 is connected to the replacem...

Embodiment 2

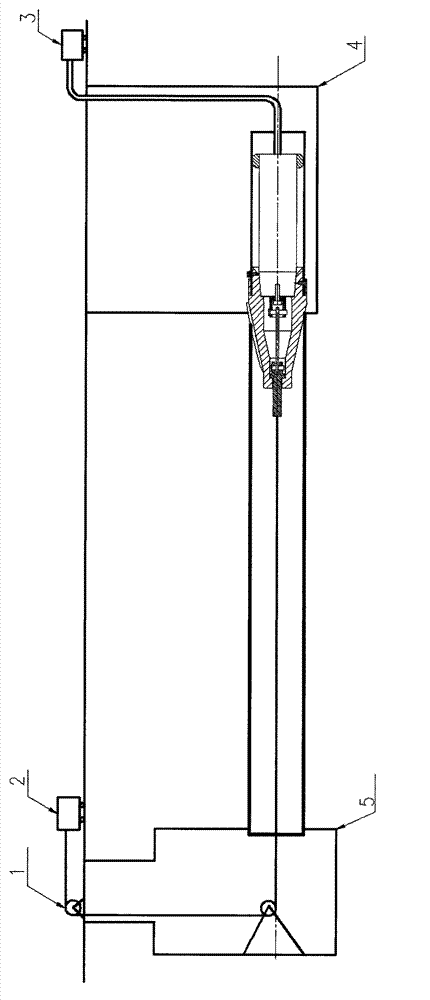

[0057] The second embodiment of the present invention proposes a system for repairing underground pipelines with non-excavation pneumatic cracked pipes, the structure of which is as follows figure 1 As shown, it includes the split pipe head 16 as described in the aforementioned first embodiment, and the excavated working pit 4 . Existing wells 5 and working pits 4 can be used in the embodiment of the present invention. Wherein, since existing underground pipelines have been provided with wells, such as sewage wells of sewer pipelines and the like. The present invention utilizes existing well 5 to cooperate with the working pit 4 of digging again to carry out work. Of course, it is also possible to re-excavate an existing well 5 to cooperate with the working pit 4, which is not limited in the present invention.

[0058]In order to make the device of the first embodiment work, the length of the working pit 4 should be at least greater than the length of the replacement pipe 13...

Embodiment 3

[0064] The third embodiment of the present invention proposes a method for repairing underground pipelines using the aforementioned trenchless pneumatic cracking pipe repairing device and system, including:

[0065] Step 1. Excavate the working pit 4 and support the working pit 4; fix the pulley block 1 in the existing well 5:

[0066] Step 2. Dredge the drainage pipe and determine whether the drainage pipe is blocked. If so, use a drilling rig to clean the pipe, and use the drilling rig to introduce the traction rope into the working pit 4; otherwise, directly use the rope guide to lay the traction rope;

[0067] Step 3. Connect the split pipe head 16 with the front conversion joint 6 in the working pit 4, and connect with the replacement pipe 13 and the pipe rammer 11; the specific connection method can be seen in the first embodiment, and will not be repeated here;

[0068] Step 4, start the hoist 2 and the air compressor 3; the traction rope of the hoist 2 can play a guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com