Deformation restraint battery pack module structure

A modular structure and battery pack technology, applied to battery pack components, structural parts, circuits, etc., can solve problems such as reduced battery life, potential safety hazards, short circuit of battery cells, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

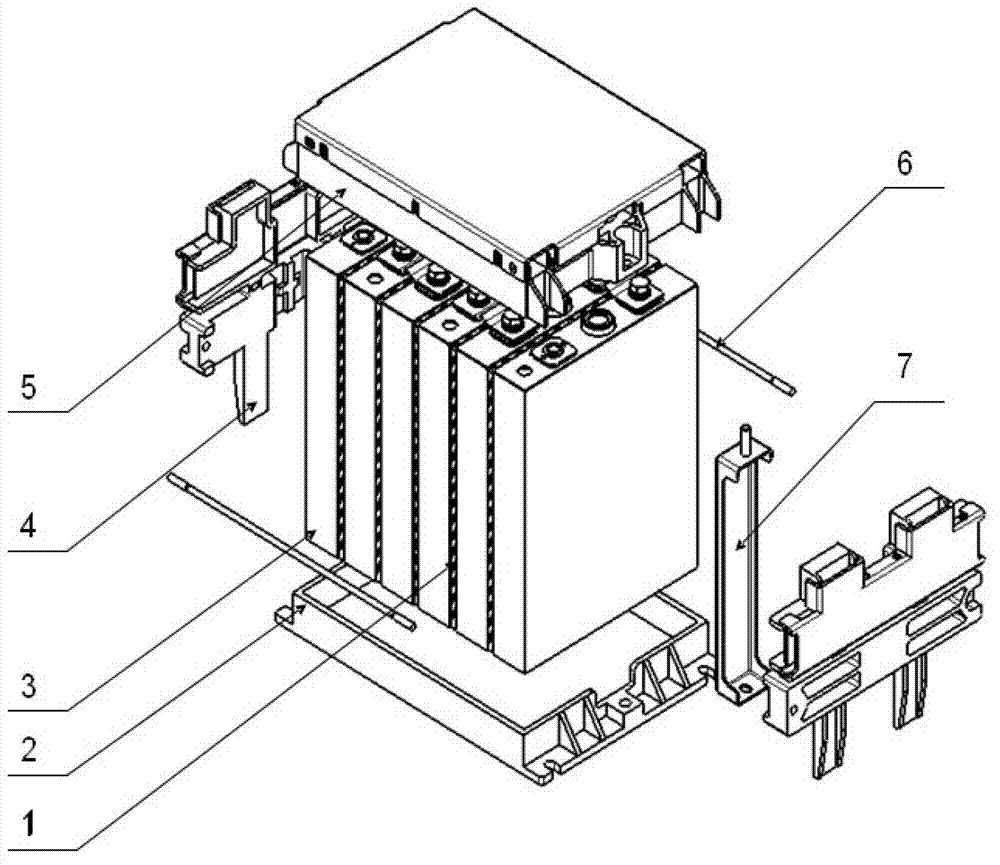

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

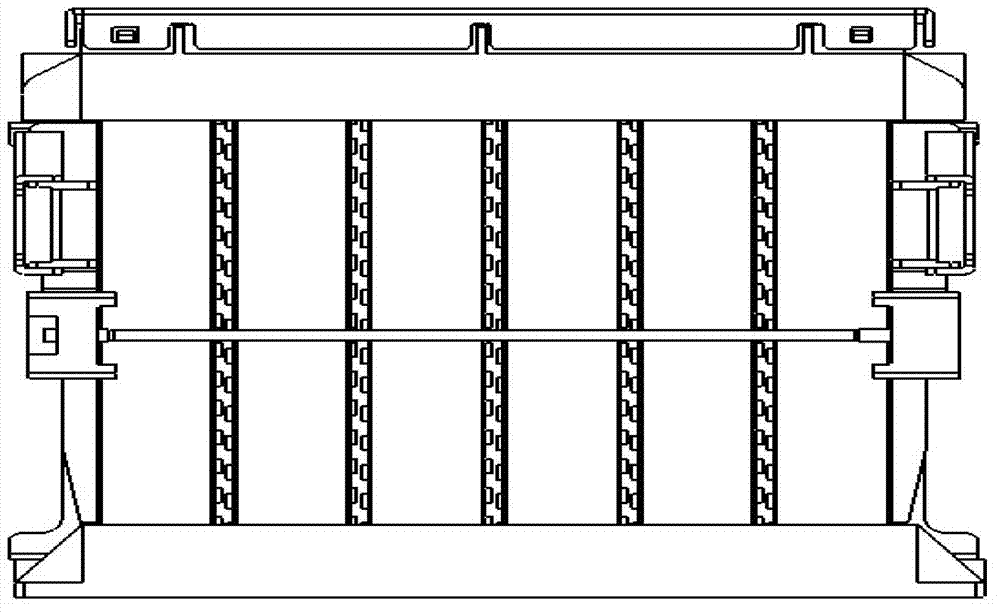

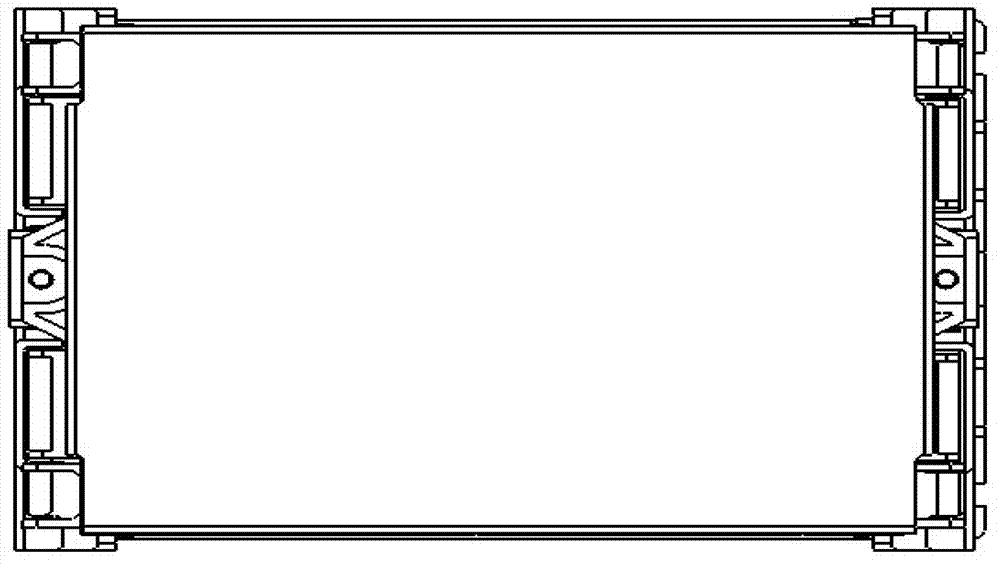

[0024] There are two types of battery pack module structures designed, vertical and horizontal; the battery pack module structure has no absolute limit on the number of battery cells, because the design ideas and principles are the same, and the battery pack module structures are similar.

[0025] There are two types of examples listed in the present invention, namely, a vertical 6-battery unit module and a horizontal 6-battery unit module. Here, only the vertical 6-battery unit module is introduced, and the horizontal 6-battery unit module has attached drawings.

[0026] The battery cell is in the shape of a cuboid, and the surface with the largest area is the front, and the opposite is the back; when facing the front, the left side is the left side, and the right side is the right side; the side closest to the ground It is the bottom surface, and the side opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com