Fully-enclosed circular reagent cabinet

A circulation type, reagent cabinet technology, applied in the direction of laboratory appliances, shells or chambers, chemical instruments and methods, etc., can solve the problems of inconvenient transfer of reagent cabinets, increased electricity bills, indoor air pollution, etc., and achieve the improvement of filter column structure , increase storage capacity, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art to which the present invention pertains can implement.

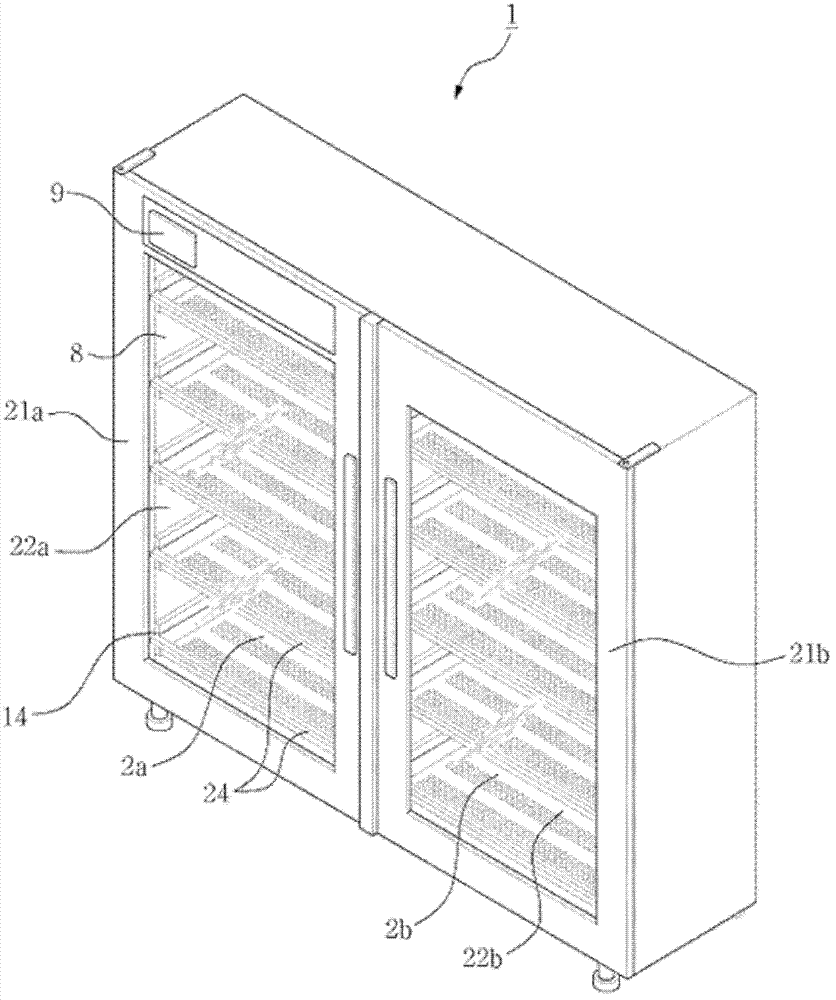

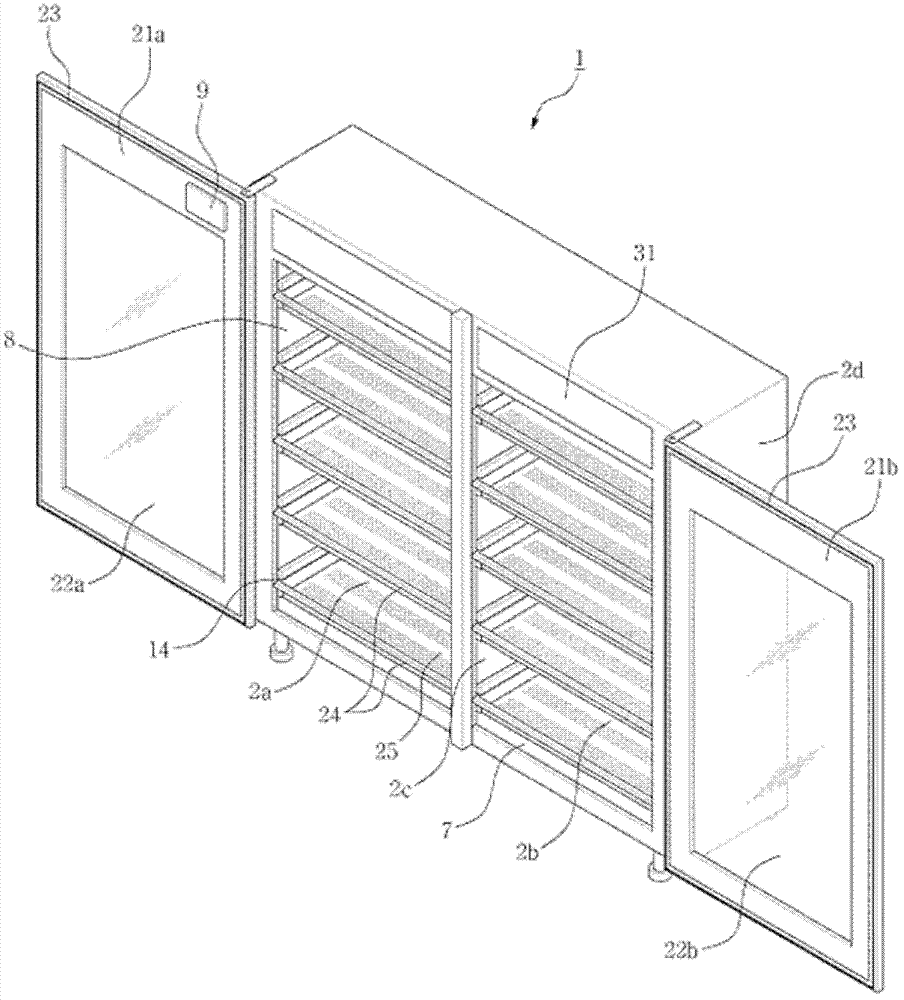

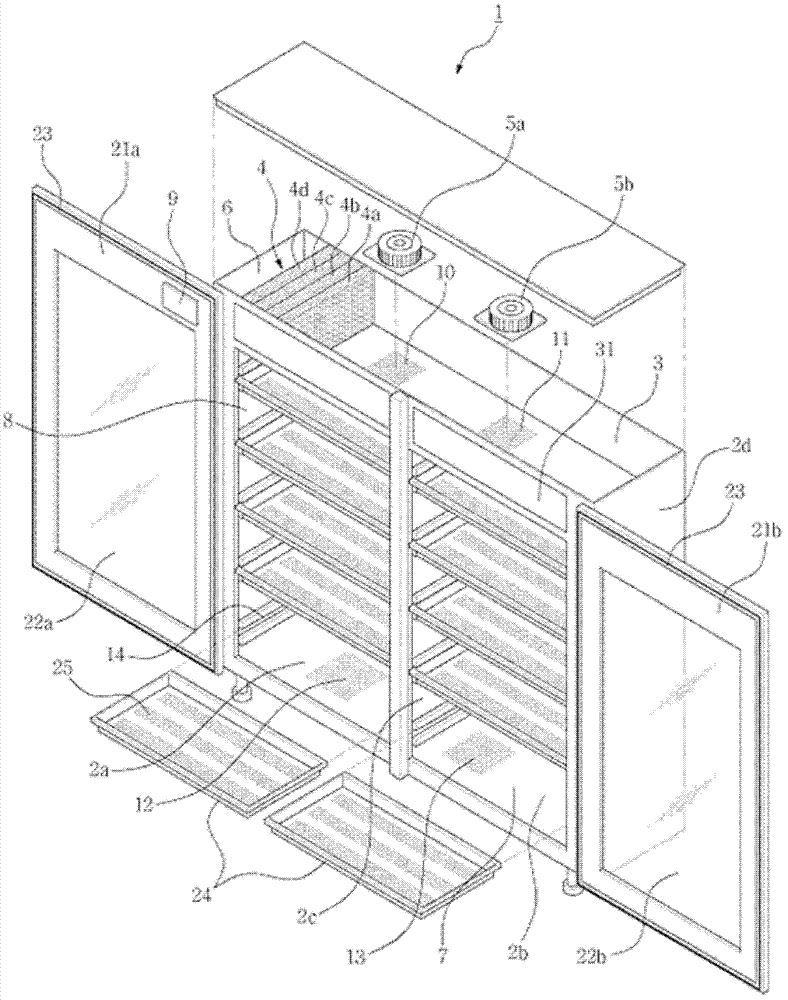

[0037] figure 1 It is a perspective view of the appearance of a fully enclosed circulation reagent cabinet according to a preferred embodiment of the present invention. figure 2 yes figure 1 The schematic diagram of the door opening state, image 3 yes figure 1 Breakdown diagram, Figure 4 yes figure 1 For the convenience of explanation, these will be described together.

[0038] First of all, according to the structure of a fully enclosed circulating reagent cabinet (1) of a preferred embodiment of the present invention, as shown in the figure, it consists of the following parts: the storage room is divided into two parts by a partition (2c) perpendicular to the central part The left and right double chambers; the reagent racks (24) that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com