Microsphere separation and screening chip and preparation method thereof

A technology for separation and screening of microspheres, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve problems such as high-precision separation and screening of microspheres with difficult target particle sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

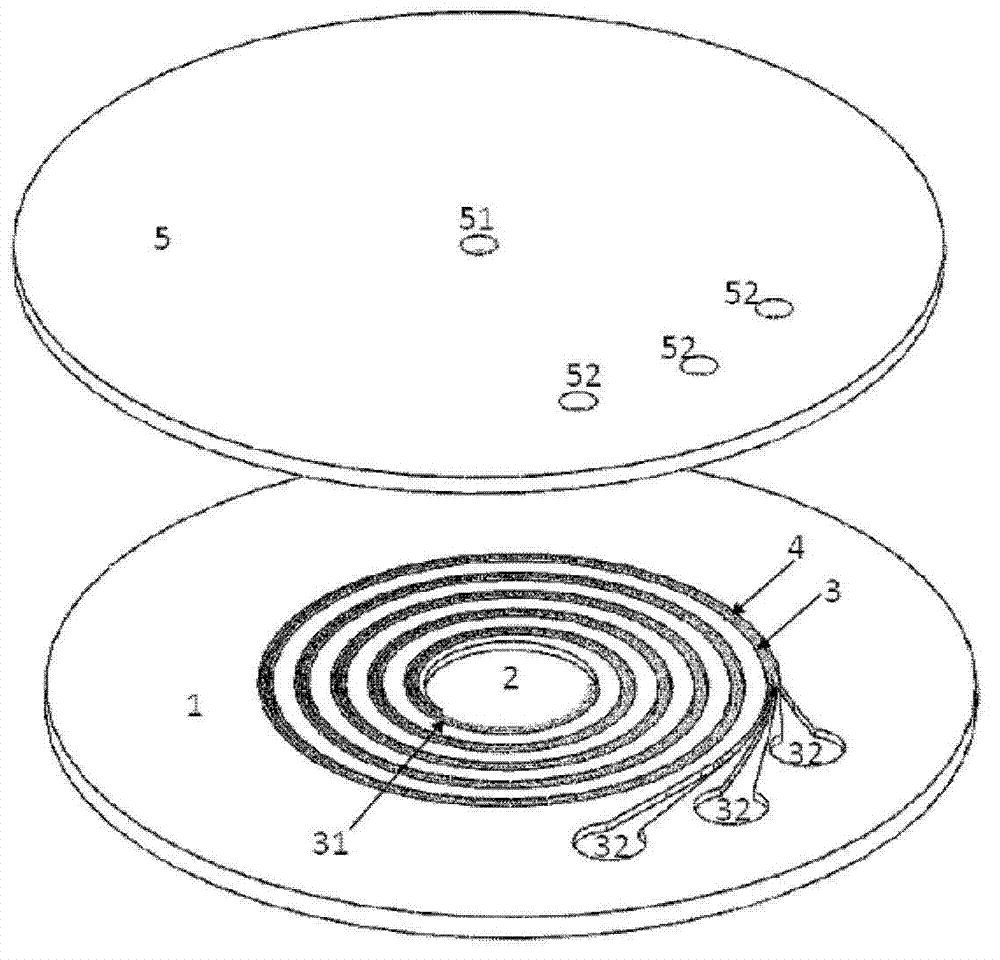

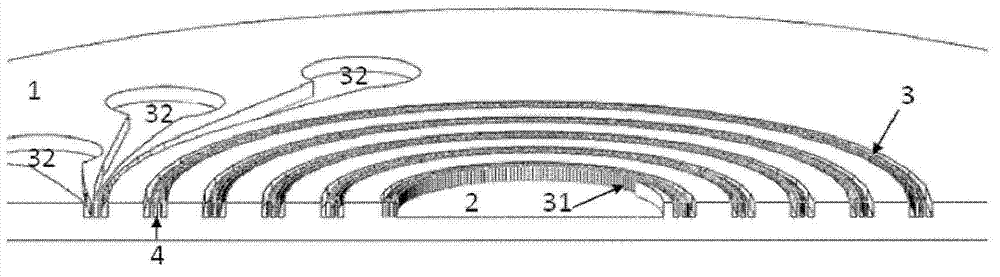

[0030] see figure 1 , figure 2 with image 3 As shown, the present invention provides a microsphere separation and screening chip, comprising:

[0031] A substrate 1, a liquid reservoir 2 is opened in the center of the substrate 1, and the material of the substrate 1 is a silicon wafer, a quartz wafer or PDMS;

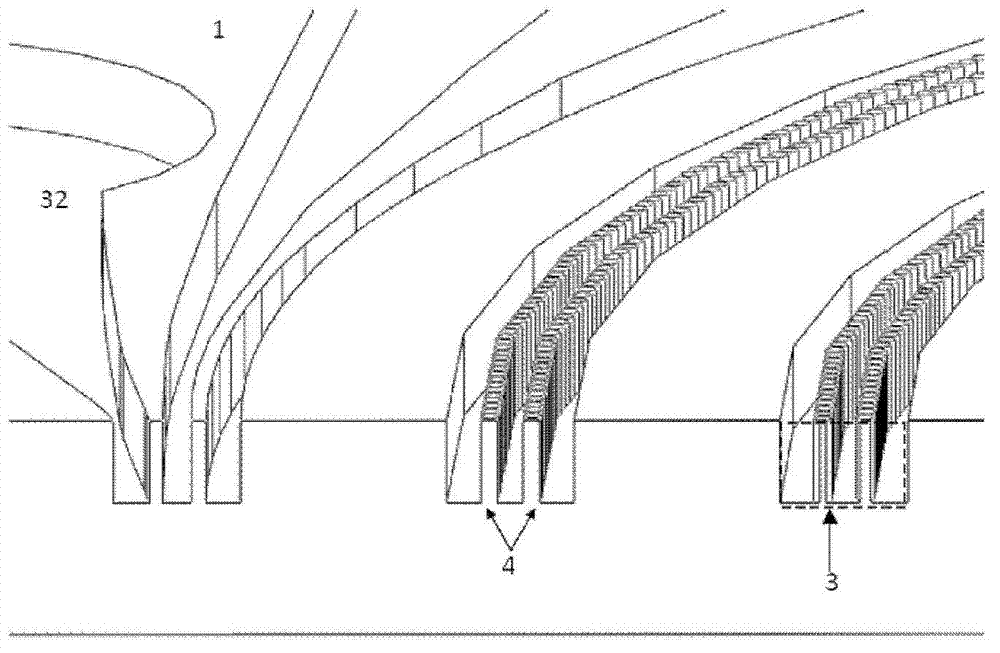

[0032] A fluid channel 3, the fluid channel 3 is helical, it is prepared on the substrate 1, the fluid channel 3 has a liquid inlet 31 and a plurality of liquid outlets 32, the liquid inlet 31 and the liquid reservoir 2 Connected, the liquid outlet 32 is located at the end of the helical fluid channel 3, the number of turns of the helical fluid channel 3 is greater than 3, the width of the fluid channel 3 is 50-500 microns, and the depth is 30-200 microns;

[0033] The filter column array 4, the filter column array 4 is prepared in the fluid channel 3, the filter column array 4 is arranged longitudinally in a row along the fluid channel 3, the column of the filte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap