Composite clamping device for rows of pipes

A technology of clamping device and knife device, which is applied in the field of composite clamping device for row pipes, can solve the problems of no saw blade holder, unstable quality of sawing section, vertical clamping and jamming, etc., so as to improve the quality of sawing section , Protect the quality of the saw cut surface, and the effect of stable and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

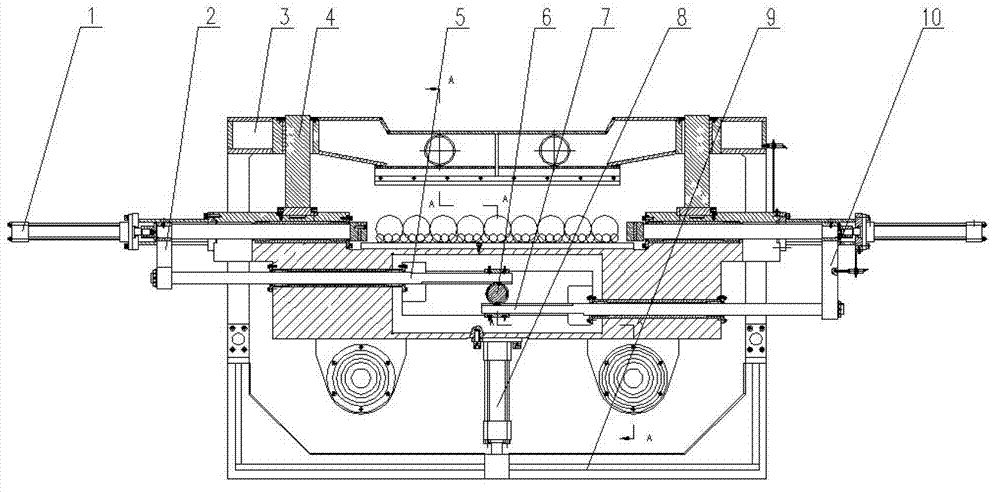

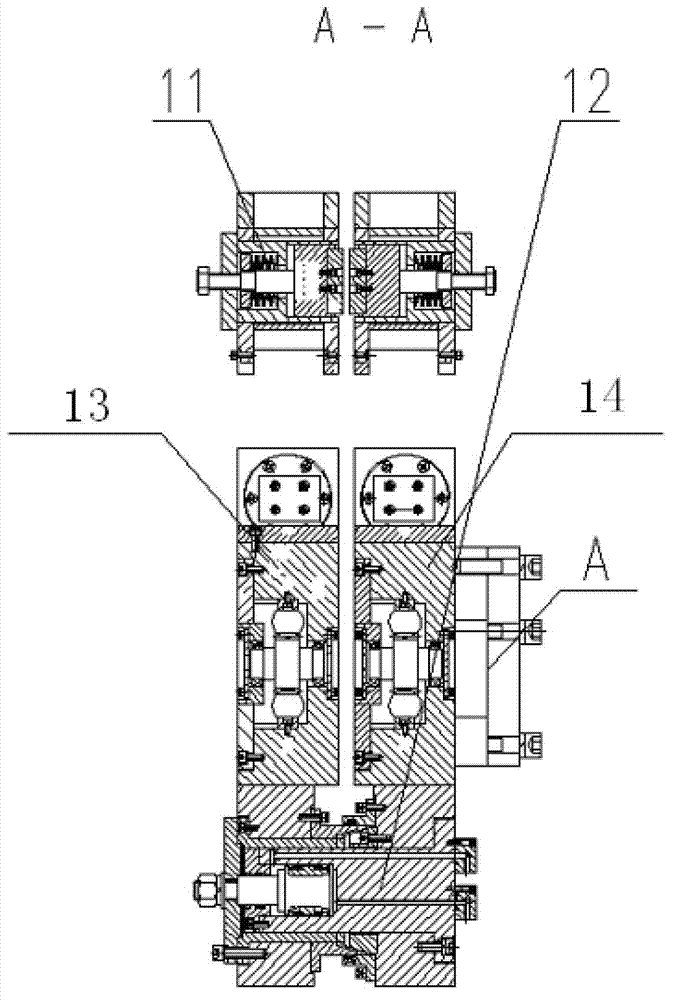

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] refer to figure 1 , figure 2 , a composite clamping device for row pipes, including a fixed clamping device 14 and a floating clamping device 13 with the same structure, the side connected to the host is the fixed clamping device 14, and the outer one is called the floating clamping device 13, The floating clamping device 13 and the fixed clamping device 14 are connected together through the piston rod of the knife device 12. The fixed clamping device 14 includes horizontal clamping oil cylinders 1 fixed on both sides of the box, and two horizontal clamping The first connecting rod 2 and the second connecting rod 10 of the oil cylinder 1 are respectively connected with the corresponding first synchronizing rack 5 and the second synchronizing rack 7, and the first connecting rod 2 and the second connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com