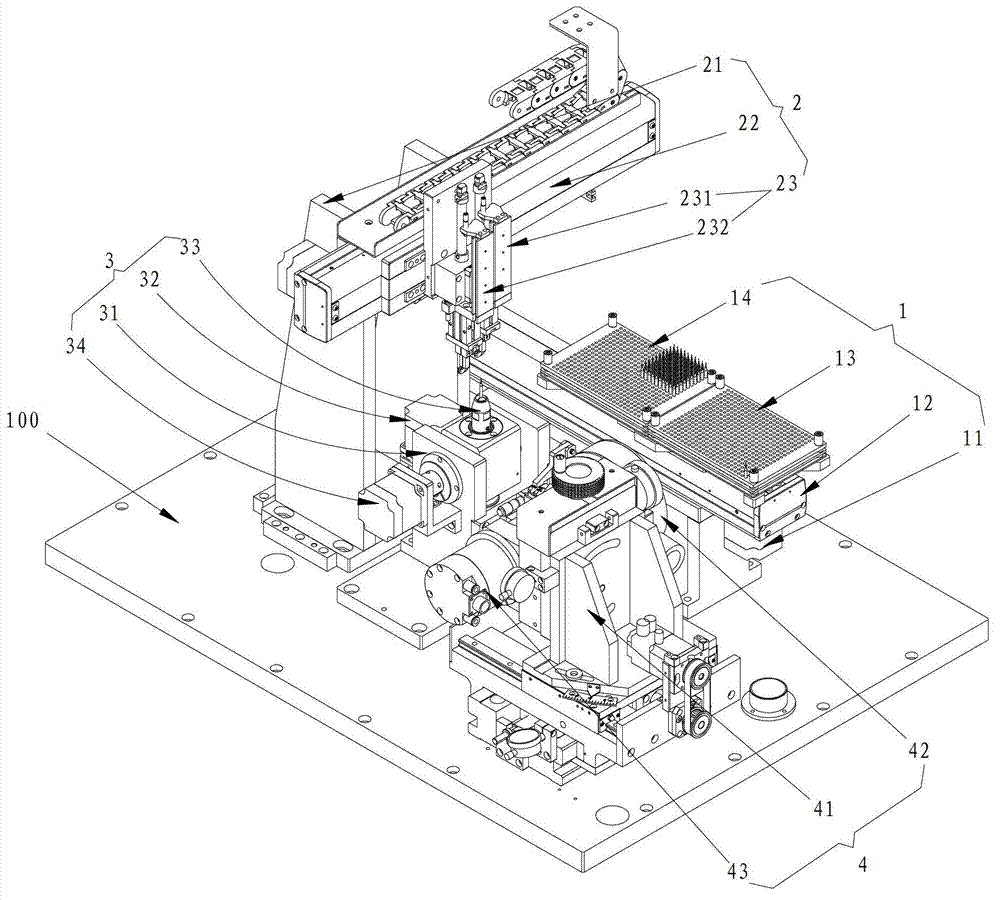

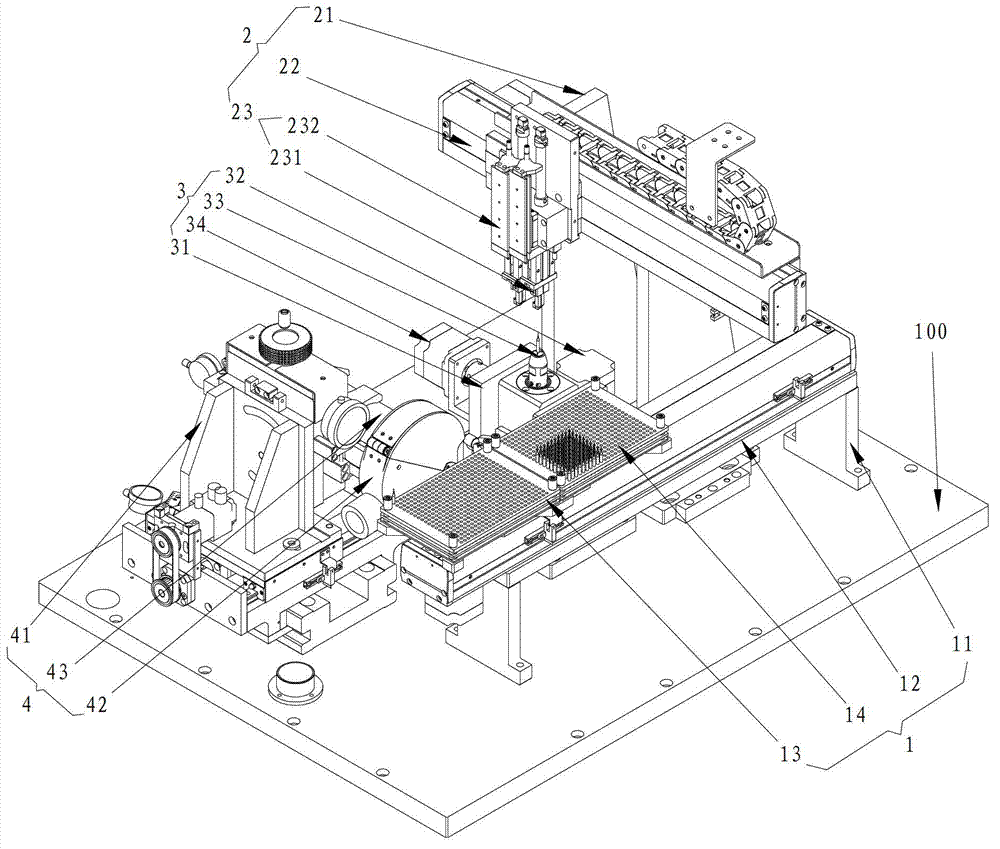

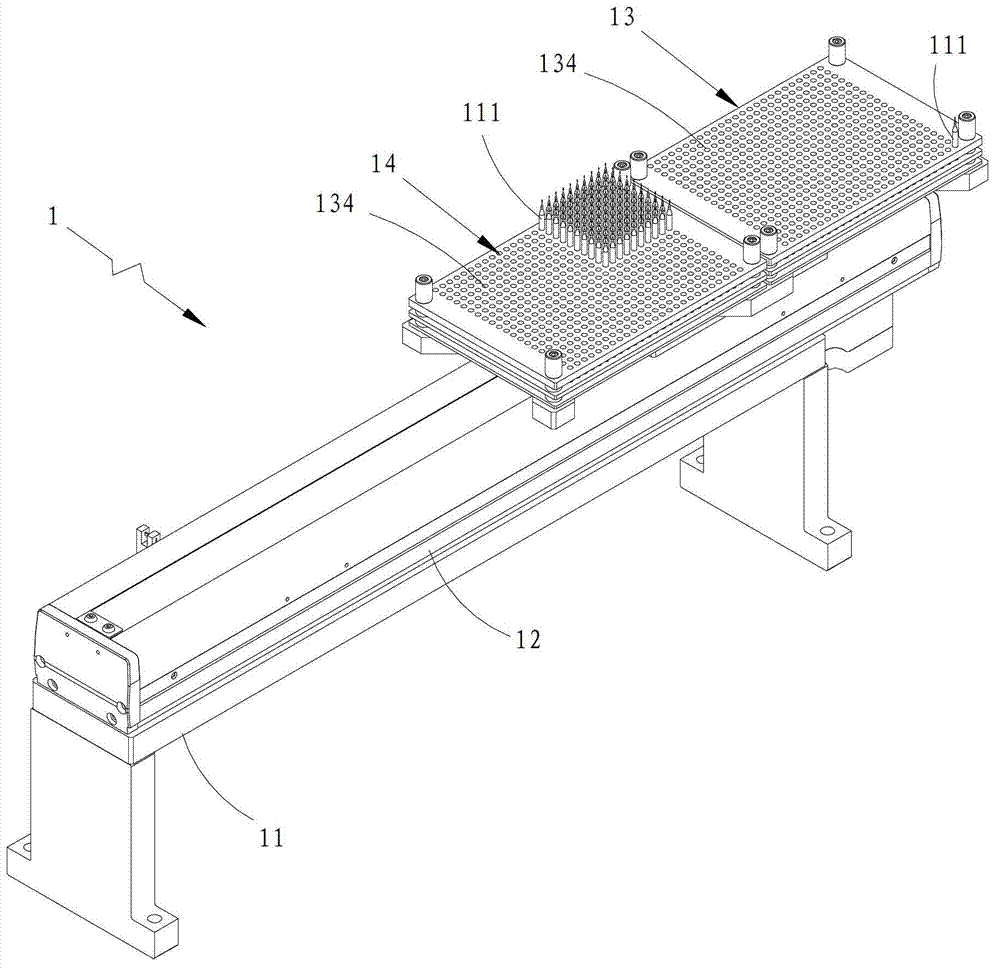

Lapping machine of milling cutters

A grinding machine and milling cutter technology, which is applied in the direction of milling cutters, grinding machine parts, milling machine equipment, etc., to achieve the effect of intelligent milling cutter grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] Further, see Figure 11 , as a specific implementation of the milling cutter grinding machine provided by the present invention, the PLC control part also includes a touch screen 200, which can be operated through the touch screen 200, and various values can be reflected on the touch screen 200, and can be displayed according to the touch screen 200 The interface sets various values, counts the processed milling cutters, and displays the time when the product is processed; it is intuitive and very convenient.

[0043] Further, see Figure 11 , the milling cutter grinder is provided with a pulley 52 below the cabinet body 51 for easy movement, and also has support feet 53 for supporting the entire cabinet body after being moved in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com