Straw crushed aggregate conveying and lifting transport system

A technology for crushed material and straw, which is applied in the field of straw crushed material conveying and hoisting transfer system, can solve the problems of unreasonable design of the hoisting mechanism, inability to be popularized and used, inconvenient to use, etc. The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

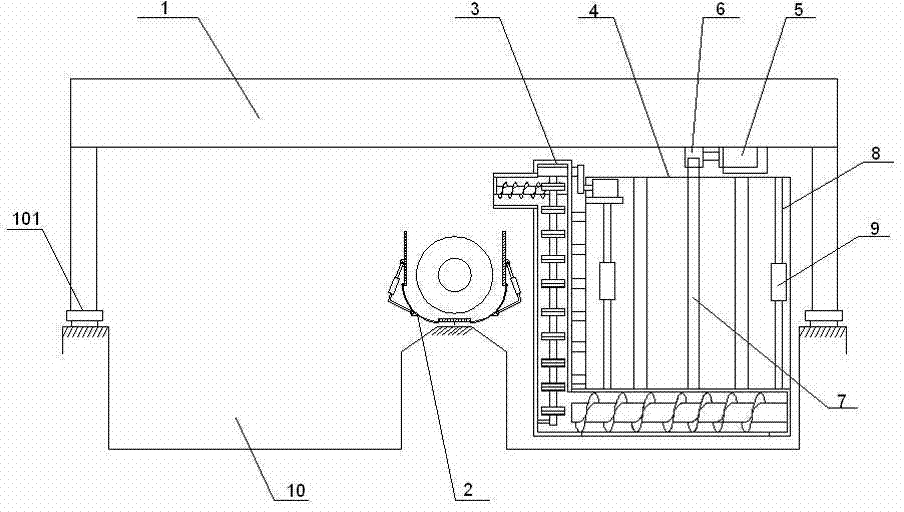

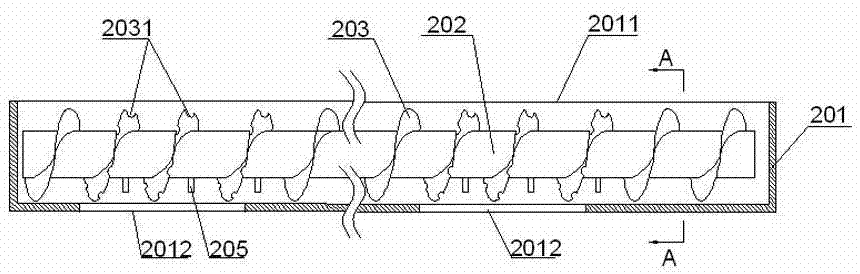

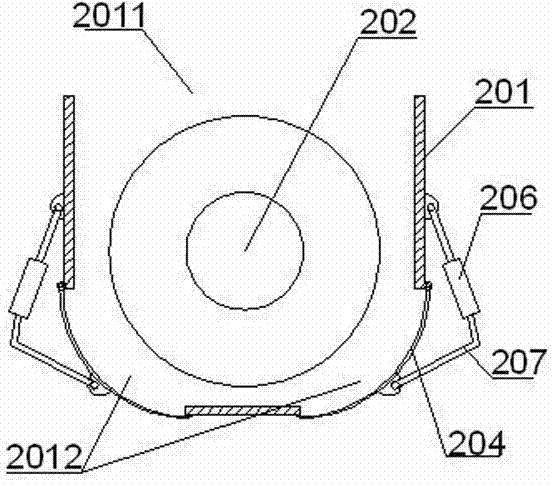

[0028] As shown in the figure, the straw crushed material conveying and lifting transfer system includes a mobile frame 1 arranged on a guide rail 101, a straw crushed material conveying device 2, a material transfer device 3, and a support frame 4 for supporting the material transfer device 1. A lifting mechanism for lifting and lowering the material transfer device and the support frame as a whole. The material transfer device 3 is connected to the support frame 1 and forms an integral structure with the support frame. The material transfer device 3, the support frame 4 and the lifting mechanism are all arranged on the mobile The frame 1 reciprocates along the direction of the guide rail with the moving frame. The discharge pipe 303 of the material transfer device 3 is located directly above the straw crushed material conveying device 2. The material transfer device drops the lifted material to the straw crushed material conveying device through its discharge port. device del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com