Method for preparation of pillared zirconium phosphate material by self-assembly technology

A self-assembly technology and zirconium phosphate column technology are applied in the field of preparing zirconium phosphate column support materials to achieve the effect of good pore structure and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

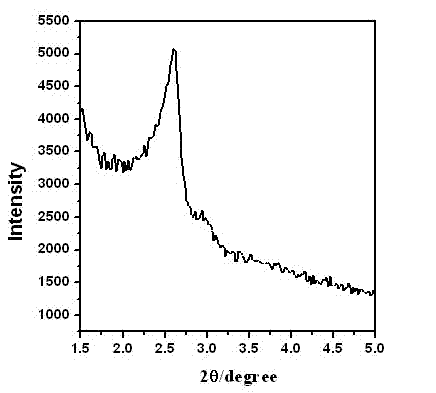

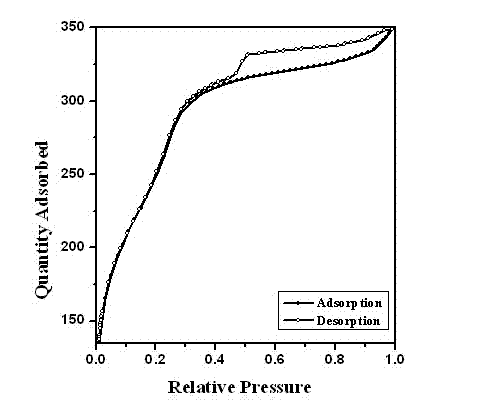

Image

Examples

Embodiment 1

[0018] Example 1: In a dry 100 mL beaker, 0.3 g of α-ZrP powder was dispersed in 28.5 mL of deionized water, and 1.5 mL of 0.2 mol.L -1 Methylamine aqueous solution, wherein the solid-to-liquid ratio is 1:100 g / mL, the molar ratio of methylamine:α-zirconium phosphate is 0.3:1, and magnetically stirred at room temperature for 2 hours. Add 20mL dropwise to the above solution with a concentration of 0.1 mol.L -1 Cetyltrimethylammonium bromide aqueous solution, wherein the molar ratio of cetyltrimethylammonium bromide: α-zirconium phosphate is 2:1, was magnetically stirred at room temperature for 4 hours. Continue to add 4.5 mL of tetraethyl orthosilicate to the above solution, wherein the molar ratio range of tetraethyl orthosilicate: α-zirconium phosphate is 20:1, and adjust the above-mentioned concentration with 25% concentrated ammonia water after magnetic stirring at room temperature for 1 hour. The pH of the solution was adjusted to 9, and the solid phase was separated by...

Embodiment 2

[0019] Example 2: In a dry 100 mL beaker, 0.3 g of α-ZrP powder was dispersed in 28.5 mL of deionized water, and 1.5 mL of 0.2 mol.L -1 Methylamine aqueous solution, wherein the solid-to-liquid ratio is 1:100 g / mL, the molar ratio of methylamine:α-zirconium phosphate is 0.3:1, and magnetically stirred at room temperature for 2 hours. Add 20mL dropwise to the above solution with a concentration of 0.1 mol.L -1 Cetyltrimethylammonium bromide aqueous solution, wherein the molar ratio of cetyltrimethylammonium bromide: α-zirconium phosphate is 2:1, was magnetically stirred at room temperature for 4 hours. Continue to add 6.7 mL of tetraethyl orthosilicate to the above solution, wherein the molar ratio range of tetraethyl orthosilicate: α-zirconium phosphate is 30:1, and then adjust the above with 25% concentrated ammonia water after magnetic stirring at room temperature for 1 hour. The pH of the solution was adjusted to 9, and the solid phase was separated by suction filtration...

Embodiment 3

[0020] Example 3: In a dry 100 mL beaker, 0.3 g of α-ZrP powder was dispersed in 28.5 mL of deionized water, and then 1.5 mL of 0.2 mol.L -1 Methylamine aqueous solution, wherein the solid-to-liquid ratio is 1:100 g / mL, the molar ratio of methylamine:α-zirconium phosphate is 0.3:1, and magnetically stirred at room temperature for 2 hours. Add 20 mL of 0.1 mol.L to the above solution drop by drop -1 Tetradecyltrimethylammonium bromide aqueous solution, wherein the molar ratio of tetradecyltrimethylammonium bromide: α-zirconium phosphate is 2:1, was magnetically stirred at room temperature for 4 hours. Continue to add 4.5 mL of tetraethyl orthosilicate to the above solution, wherein the molar ratio range of tetraethyl orthosilicate: α-zirconium phosphate is 20:1, and adjust the above-mentioned concentration with 25% concentrated ammonia water after magnetic stirring at room temperature for 1 hour. The pH of the solution was adjusted to 9, and the solid phase was separated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap