Biological fermentation liquor dewatering device and using method thereof

A technology for biological fermentation and fermentation broth, applied in the direction of adsorbed water/sewage treatment, etc., can solve the problems of high energy consumption and increase production cost, and achieve the effects of flexible use, reduced loss and high promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

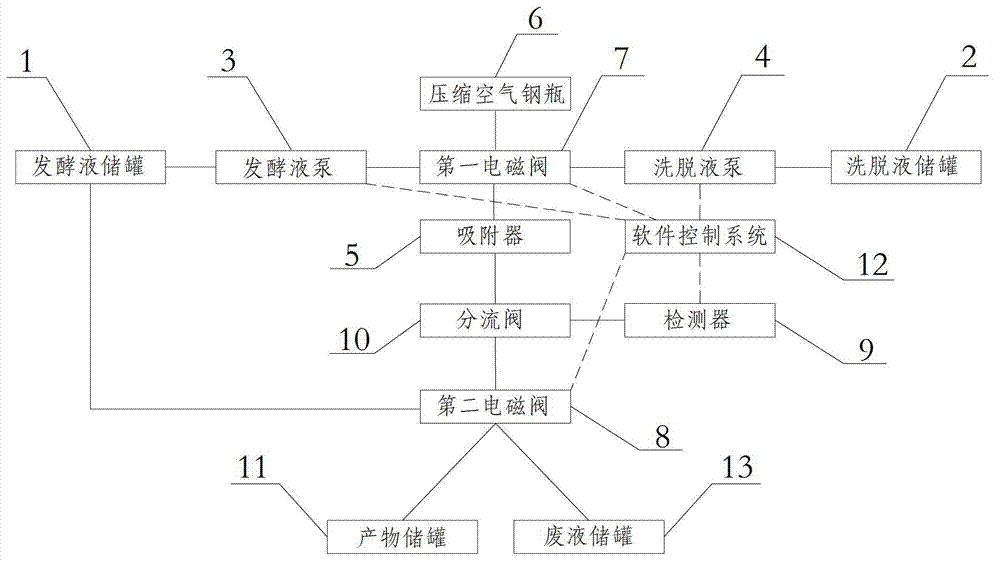

[0025] Adjust the first solenoid valve 7 and the second solenoid valve 8 so that the fermentation broth storage tank 1, the fermentation broth pump 3, the adsorber 5 and the waste liquid storage tank 13 form a passage, turn on the fermentation broth pump 3, and the 1000ml fermentation broth at a rate of 5ml / min The flow rate passes through the adsorber 5, and the effluent from the adsorption column 5 is split through the split valve 10 at a split ratio of 1:50. When the detector 9 has a chromatographic peak, the software control system 12 sends an instruction to turn off the fermentation liquid pump 3, adjust the first solenoid valve 7 and the second solenoid valve 8 to make the compressed gas cylinder 6, the adsorber 5, and the fermentation liquid storage tank 1. A passage is formed, and the gas in the compressed gas cylinder 6 blows the residual fermentation liquid in the adsorber 5 back into the fermentation liquid storage tank 1 at a flow rate of 3 ml / min. When a sharp bubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com