Vertical roller mill rotary feed device

A rotary blanking, vertical roller mill technology, applied in cement production and other directions, can solve the problems of shortened service life, rapid rotor blade wear, jammed parking, etc., to reduce mill air leakage, overcome jamming, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

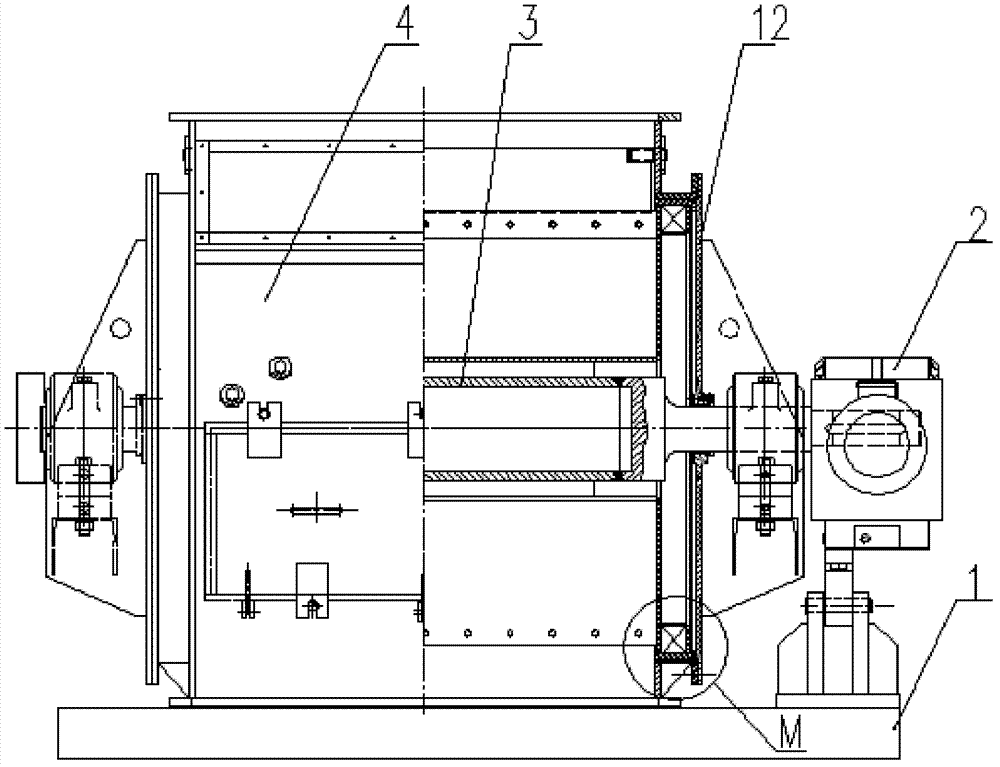

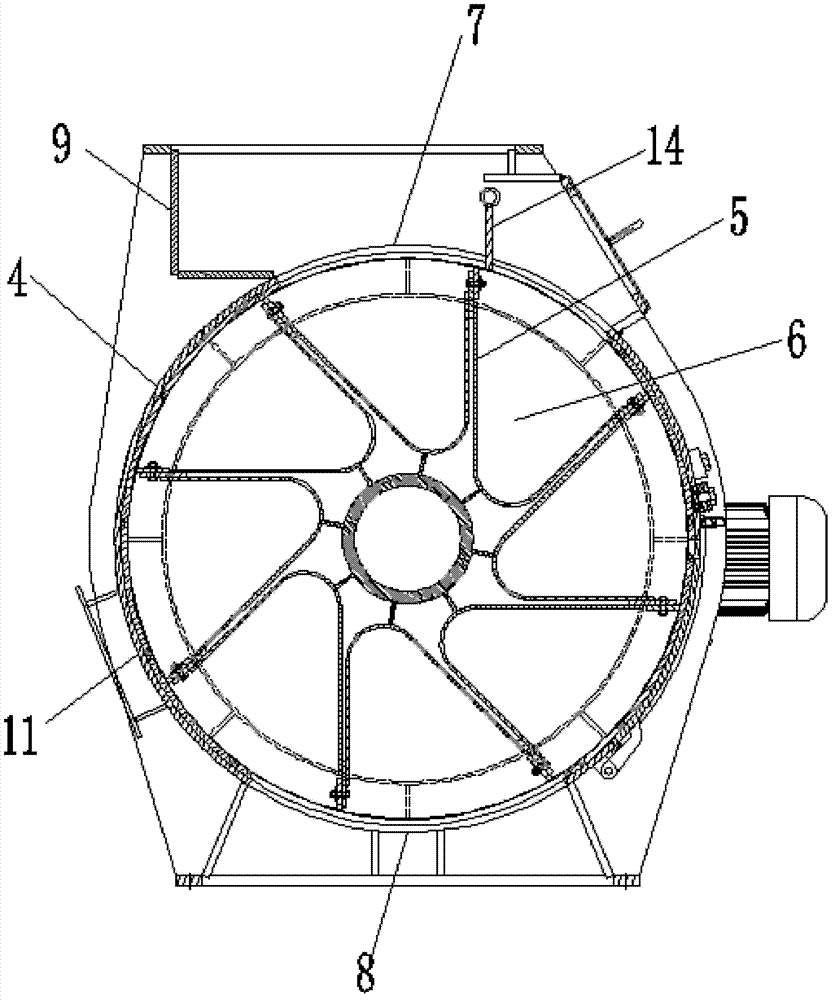

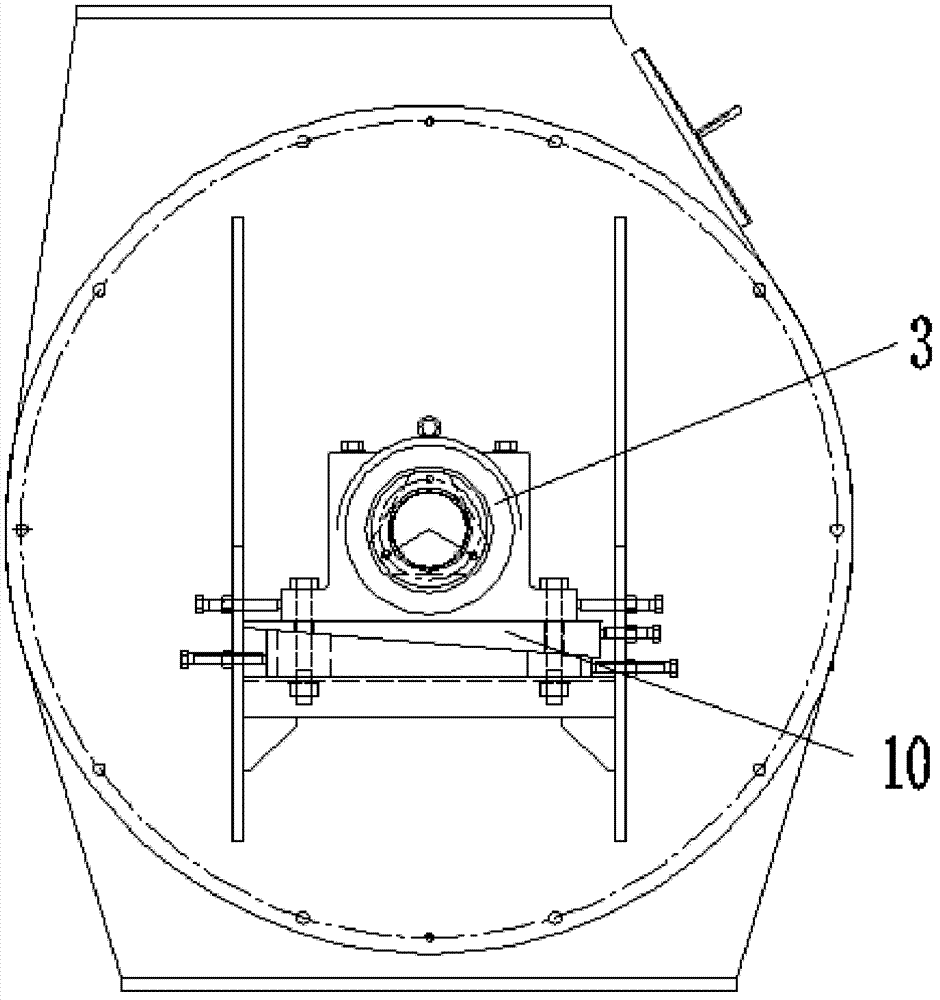

[0018] A vertical roller mill rotary feeder, including a base 1 and a reducer motor 2, a rotor 3 and a housing 4 arranged on the base, the reducer motor controls the rotation of the rotor; eight blades 5 are fixed on the outer periphery of the rotor, And a hopper 6 is formed between every two blades; the housing is fixed on the periphery of the blades; the top and bottom of the housing are respectively provided with a feed inlet 7 and a discharge port 8, and the eight blades on the rotor are Eccentric, and the hopper formed by it is also eccentric. In this way, the motor of the reducer drives the rotor and the hoppers on it to rotate, so that different hoppers enter the feed inlet in turn to feed, and then rotate to the outlet to discharge. When a hopper has just been rotated by the rotor and enters the feed port, the material will hit the blade on one side of the rotor at the beginning, but because the hopper is eccentric, the material and the side of the hopper will be in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com