High-efficiency low-radiation dose irradiation crosslinking polyethylene insulation material and preparation method thereof

A technology of cross-linked polyethylene and insulating materials, applied in organic insulators, plastic/resin/wax insulators, etc., can solve the problems of wasting energy consumption, increasing costs for manufacturers, consuming time, manpower, and financial resources, and reducing manufacturing costs. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

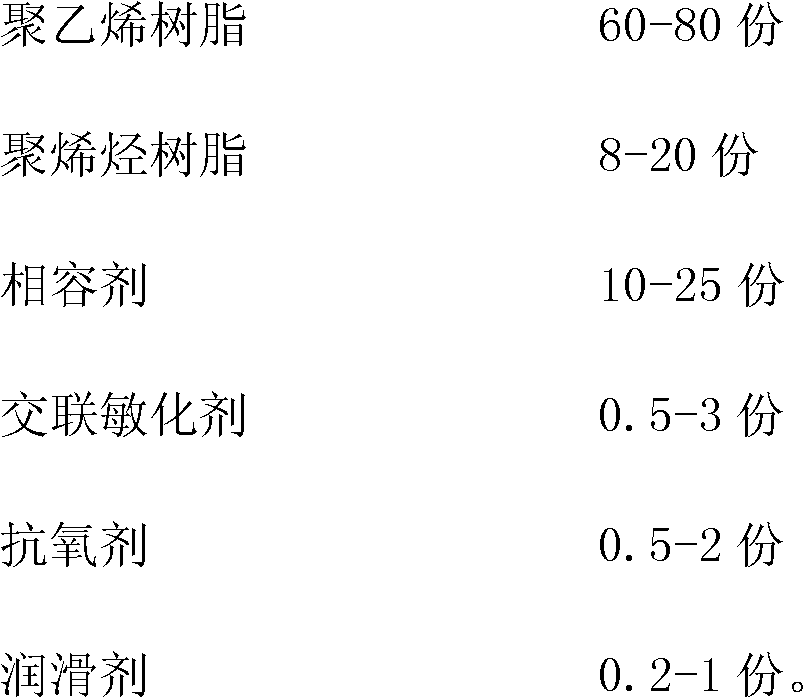

Method used

Image

Examples

Embodiment 1~ Embodiment 4

[0025] A method for preparing an irradiation cross-linked polyethylene insulating material with high efficiency and low radiation dose, the method comprises the following steps:

[0026] (1) according to the component listed in the embodiment in table 1 and content batching;

[0027] (2) Put the above raw materials into a high-speed mixer and mix at high speed (1500-3000rpm) for about 1-3 minutes;

[0028] (3) Low-speed (500-1000rpm) discharge;

[0029] (4) Put the mixed raw materials into a twin-screw machine to extrude and granulate. The speed of the extruder is controlled at 180-600 rpm, and the temperature is set as: feeding section 145-155°C, mixing section 155-165°C, extrusion material section 160-165°C, flange part 165-175°C , head part 175-185 ℃, made of high-efficiency and low radiation dose of radiation cross-linked polyethylene insulating material.

[0030] The formula table (unit: parts by weight) of the embodiment 1~4 of table 1

[0031] raw material ...

Embodiment 5-6

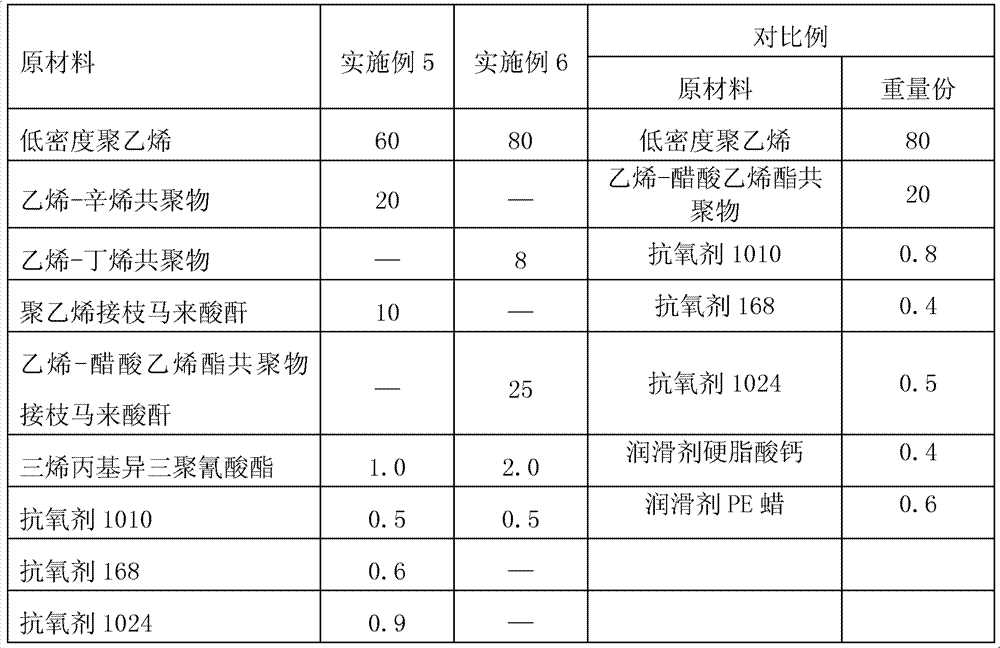

[0038] The formula table (unit: parts by weight) of table 3 embodiment 5~6

[0039]

[0040]

[0041] The high-efficiency and low-radiation dose irradiated cross-linked polyethylene insulating materials prepared in Examples 5, 6 and Comparative Example were subjected to performance tests after irradiation, and the results are shown in Table 4.

[0042] Table 4 Performance of irradiated cross-linked polyethylene insulating material with high efficiency and low radiation dose

[0043] Test items

[0044] The test samples of the above-mentioned examples 5 and 6 were all irradiated with a radiation dose of 10-15Mard once to form, and the test samples of the comparative example were formed with a radiation dose of 25Mard once. It can be seen from the performance testing results that after the test sample prepared by the present invention is irradiated with a low radiation dose, all properties can meet the standard requirements, which is a good way to reduce energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com