Linear water curtain device

A straight line and water curtain technology, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of straight seam deformation, large hardness dispersion of quenched pipe body, drill pipe fracture, etc., and achieve uniform thickness, uniform mixing and consistent flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

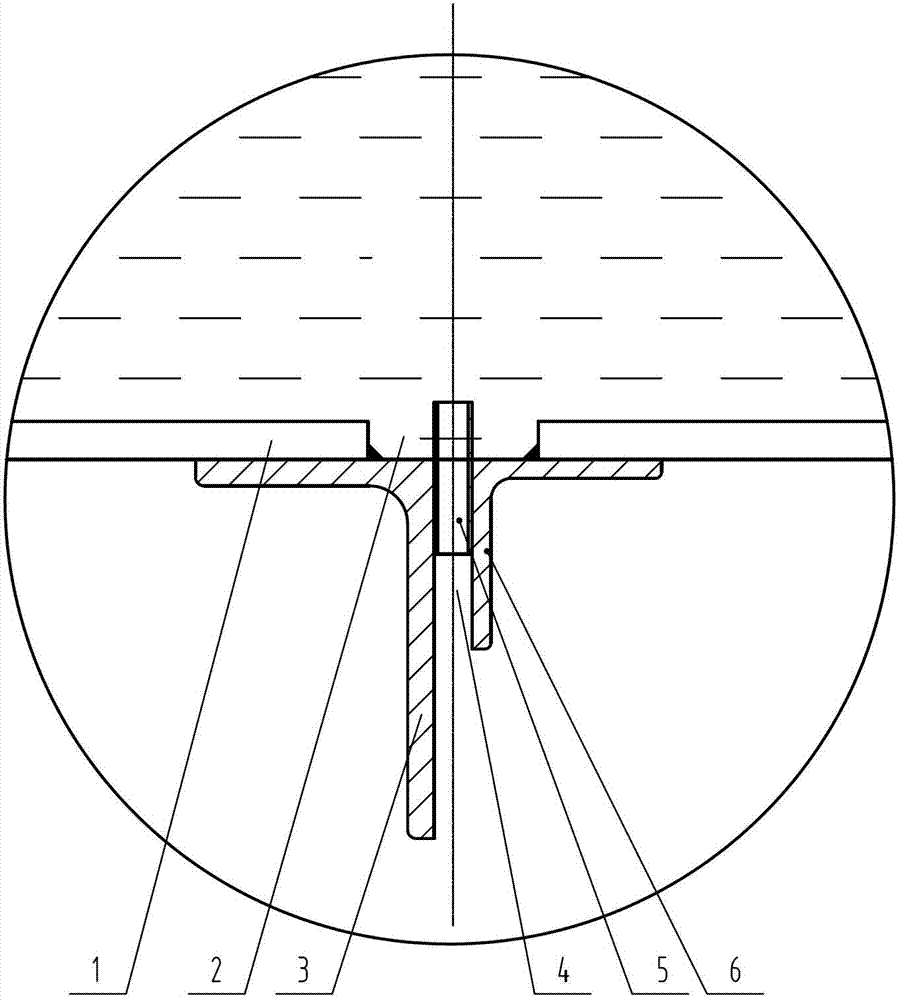

[0012] figure 1 Among them, it includes water tank 1, straight seam 2, straight water outlet 3, quantitative mixing area 4, quantitative pipe 5, high mixing edge 6, etc.

[0013] Such as figure 1 Shown, the present invention is a kind of linear water curtain device, comprises water tank 1, and the bottom of water tank 1 has straight seam 2.

[0014] In the present invention, a straight water outlet 3 and a high-level mixing edge 6 are respectively fixed on both sides below the straight seam 2 . The high mixing edge 6 and the straight water outlet 3 respectively adopt angle steel, the high mixing edge 6 adopts equilateral angle steel, and the straight water outlet 3 adopts unequal angle steel. The high mixing side 6 and the straight water outlet 3 are arranged back to back, and the bottom of the high mixing side 6 is higher than the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com