Preparation method of ultra-high-purity arsenic monocrystal pieces

A technology of single crystal and single wafer, which is applied in the field of preparation of ultra-high purity arsenic single crystal wafers, achieving the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for preparing an ultra-high-purity arsenic single crystal sheet, characterized in that it comprises the following steps:

[0073] (1) Surface treatment of quartz tube

[0074] (1.1) First wash off the white silica attached to the surface of the quartz tube with hydrofluoric acid;

[0075] (1.2) Soak the quartz tube in aqua regia for 1 day, and remove the impurities on the surface by acid etching;

[0076] (1.3) Clean the quartz tube with high-purity water and dry it in an infrared lamp drying oven.

[0077] (2) Ultra-high purity arsenic deoxidation packaging

[0078] Put ultra-high-purity arsenic with a purity of 7N into a cleaned quartz tube, place it in an electric furnace at a temperature of 500°C, and evacuate it to 10 -2 Pa, take off the oxide film on the surface of arsenic to make the surface of arsenic show a metallic luster, and seal the quartz tube with a hydrogen-oxygen flame lamp.

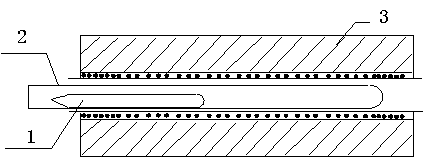

[0079] (3) Placed in a horizontal tube furnace

[0080] (3.1) U...

Embodiment 2

[0089] A method for preparing an ultra-high-purity arsenic single crystal sheet, characterized in that it comprises the following steps:

[0090] (1) Surface treatment of quartz tube

[0091] (1.1) First wash off the white silica attached to the surface of the quartz tube with hydrofluoric acid;

[0092] (1.2) Soak the quartz tube in aqua regia for 1 day, and remove the impurities on the surface by acid etching;

[0093] (1.3) Clean the quartz tube with high-purity water and dry it in an infrared lamp drying oven.

[0094] (2) Ultra-high purity arsenic deoxidation packaging

[0095] Put ultra-high-purity arsenic with a purity of 7N into a cleaned quartz tube, place it in an electric furnace at a temperature of 600°C, and evacuate it to 10 -3 Pa, take off the oxide film on the surface of arsenic to make the surface of arsenic show a metallic luster, and seal the quartz tube with a hydrogen-oxygen flame lamp.

[0096] (3) Placed in a horizontal tube furnace

[0097] (3.1) U...

Embodiment 3

[0106] A method for preparing an ultra-high-purity arsenic single crystal sheet, characterized in that it comprises the following steps:

[0107] (1) Surface treatment of quartz tube

[0108] (1.1) First wash off the white silica attached to the surface of the quartz tube with hydrofluoric acid;

[0109] (1.2) Soak the quartz tube in aqua regia for 1 day, and remove the impurities on the surface by acid etching;

[0110] (1.3) Clean the quartz tube with high-purity water and dry it in an infrared lamp drying oven.

[0111] (2) Ultra-high purity arsenic deoxidation packaging

[0112] Put ultra-high-purity arsenic with a purity of 7N into a cleaned quartz tube, place it in an electric furnace at a temperature of 550°C, and evacuate it to 10 -3 Pa, take off the oxide film on the surface of arsenic to make the surface of arsenic show a metallic luster, and seal the quartz tube with a hydrogen-oxygen flame lamp.

[0113] (3) Placed in a horizontal tube furnace

[0114] (3.1) U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com