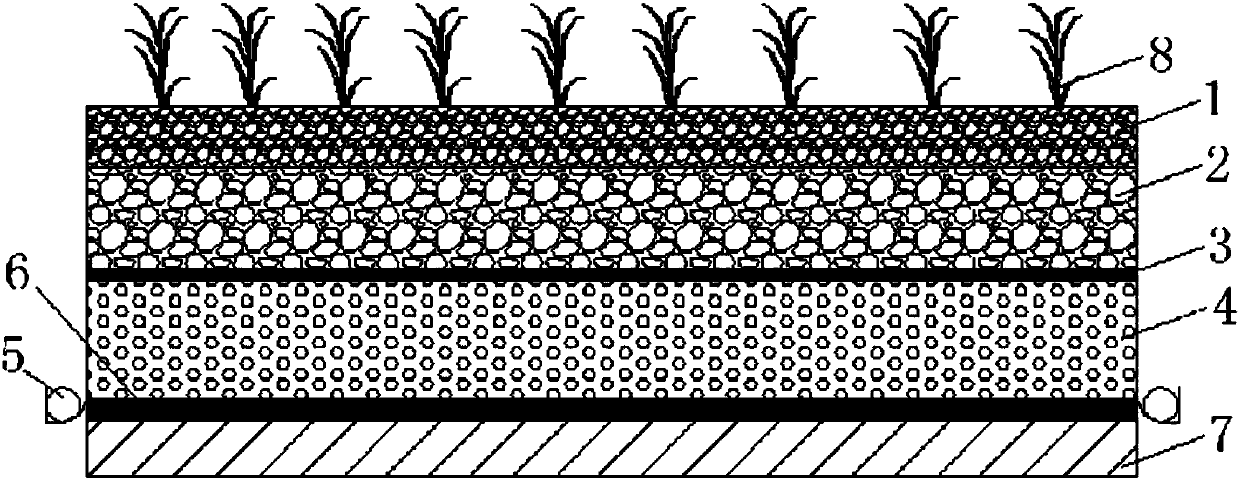

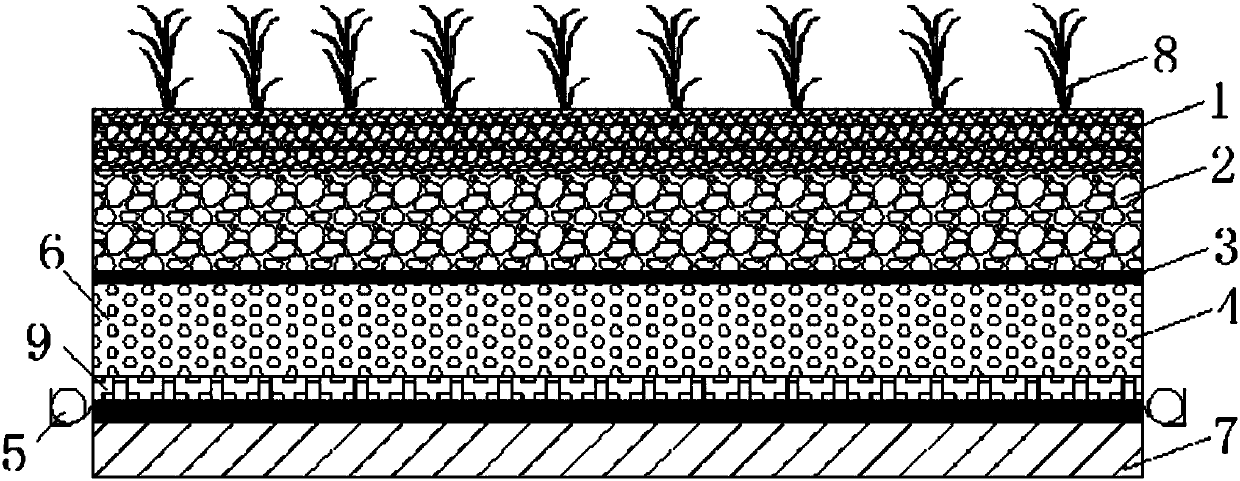

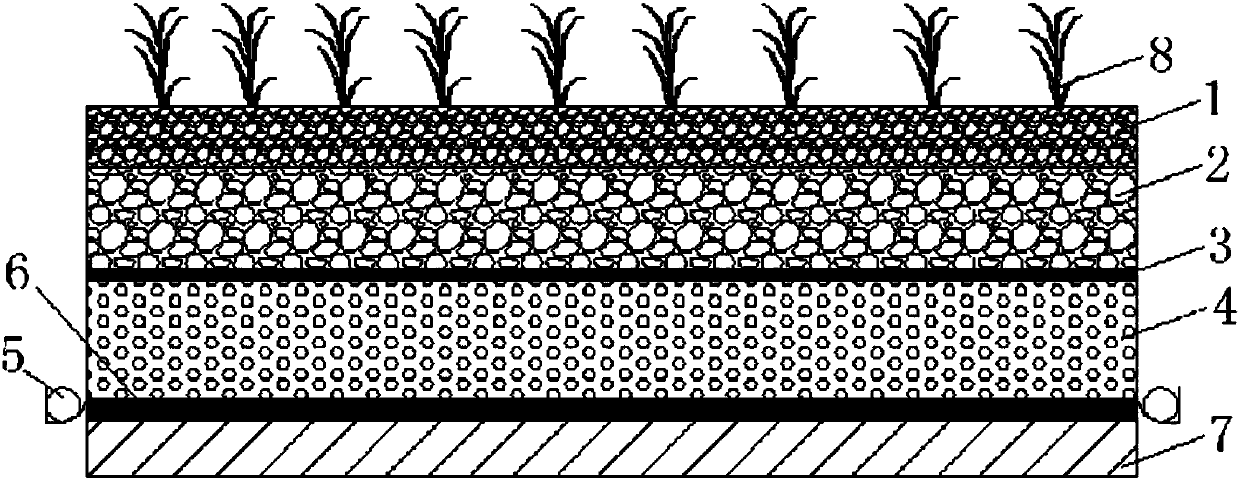

Grass planting ecological sponge type bituminous mixture pavement structure

A technology of asphalt mixture and pavement structure, applied in fertilizer mixture, roads, roads, etc., can solve the problems of no water purification effect, no greening effect, easy blockage of pores, etc., and achieve good physical, chemical and biological characteristics, reasonable Strength and mechanical properties, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Fine asphalt mixture layer: take: rock asphalt, E-51 epoxy resin, methyl hexahydrophthalic anhydride and hydrophilic additives, use shear mixing method, control the stirring rate at 2500r / min, at 100 Stir at a stirring temperature of ~150°C for 60-70 minutes and stop stirring when the uniformity of the mixture is good;

[0053] Pour the prepared plant-type asphalt mixture into the container, develop it in a constant temperature box at 150°C for about 1 hour, take it out, and then stir it at 150°C for 10 minutes, and then it can be poured into a fine asphalt mixture layer. Block structure, and finally control the stable ambient temperature and humidity for maintenance.

[0054] Concrete raw material proportioning ratio is as shown in table 1 below:

[0055] Table 1

[0056] Example 1 (unit serving) 2 (unit servings) 3 (unit servings) rock asphalt 80 82 84 E-51 epoxy resin 8 7 7.5 Methylhexahydrophthalic anhydride 4 3 3.5 Hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com