Double-tracing thin layer recognizer

An identifier and dual tracer technology, which is applied in construction and other directions, can solve problems such as contamination, and achieve the effect of improving measurement accuracy and enriching information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

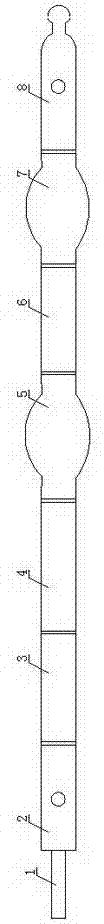

[0033] Such as figure 1 As shown, the dual tracer thin-layer identifier includes a liquid releaser, a remote four-parameter receiver, a single gamma meter, an upper centralizer, an ultrasonic flowmeter, a lower centralizer, and a solid releaser, which are connected in sequence, and each part is specific The structure is:

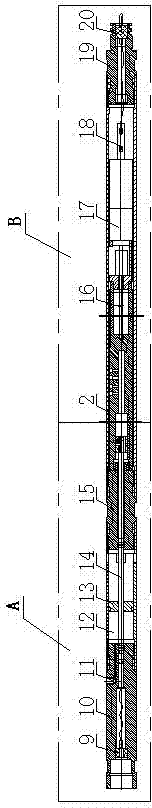

[0034] Such as figure 2As shown, the specific structure of the liquid release device 2: the upper joint 10 of the liquid release device 2 is provided with a single-core socket-9, and the upper and lower ends of the upper joint 10 are respectively provided with threads, and the radial direction is provided with a liquid injection hole 11, and the liquid injection The inner end of hole 11 is connected with liquid source bin 12, liquid Ba131 radiotracer is housed in liquid source bin 12, is provided with piston one 13 in the liquid source bin 11, is provided with piston rod one 14 in the middle of piston one 13, piston rod one 14 is connected to the screw dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com