Device and method for buffering main oil cylinder of paste filling pump in coal mine

A paste filling and cushioning device technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of poor cooperation between the buffer ring and the buffer hole, complex structure, and unstable operation of the buffer device, so as to achieve simple structure and avoid processing difficulty Great, work-stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

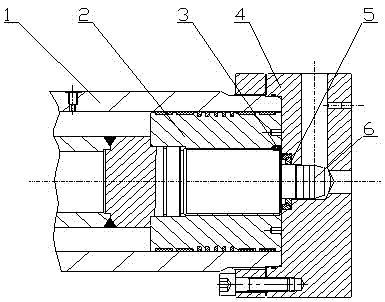

[0016] Embodiment 1: The buffering device and method of the main oil cylinder of the coal mine paste filling pump according to the present invention;

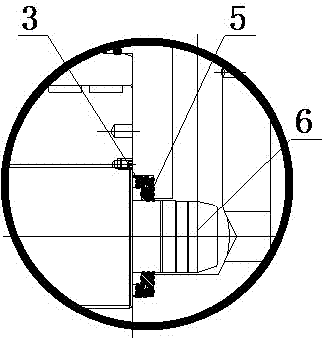

[0017] The device comprises: a cylinder 1, a piston 2, a limit cover 3, a cylinder bottom 4, a floating throttle ring 5 and a piston rod 6; the cylinder bottom 4 is connected to one end of the cylinder 1, and the piston 2 is located in the cylinder 1 , the limit cover 3 is connected with the cylinder bottom 4, and the floating throttle ring 5 is installed between the limit cover 3 and the cylinder bottom 4; the tail post of the piston rod 6 is inserted into the floating throttle ring 5; the piston rod 6 and the piston 2 are threaded connected.

[0018] The tail post of the described piston rod 6 is a stepped structure.

[0019] There are grooves on the 5th circumference of the floating throttle ring, and there are six grooves, which are evenly distributed on the circumference of the floating throttle ring. There is a guide ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com