Gear measuring device

A gear measurement and gear technology, which is applied in the field of gear fixed measurement devices, can solve the problems of shortening the service life of gears, destroying the normal meshing of gear pairs, destroying the uniformity of gear distribution, etc., and achieving the effect of reducing the weight of the device and having strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

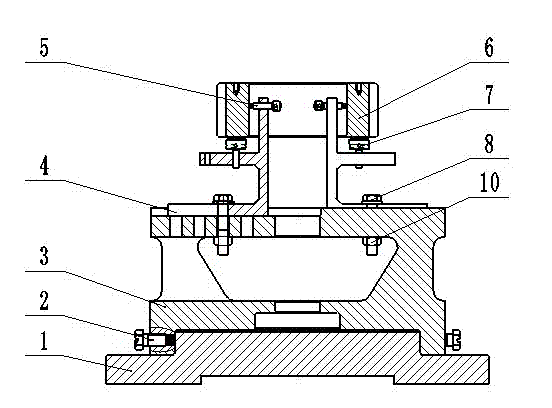

[0010] like figure 1 As shown, a gear measuring device includes a workbench 1, a base 3 arranged on the top of the workbench 1, the base 3 is provided with 4 grooves, the groove is provided with a bracket 4, and the bracket 4 It is fixedly connected with the groove by a hexagonal bolt 8 and a hexagonal nut 10. The gear 6 to be tested is placed on the short beam of the bracket 4, and a leveling screw 7 is arranged between the gear 6 and the short beam of the bracket 4. The gear 6 to be tested and the bracket 4 are tightly fixed by the tightening screw 5 .

[0011] The workbench 1 and the base 3 are connected by four combined compression screws 2 . The base 3 is a hollow casting with 4 ribs inside. Copper sleeves are welded at the ends of the four combined compression screws 2 .

[0012] During actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com