7/16 negative connector

A connector and female technology, which is applied in the field of 7/16 female connectors, can solve problems such as low work efficiency, large operating space, and design difficulties, and achieve the effects of reducing device weight, improving work efficiency, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

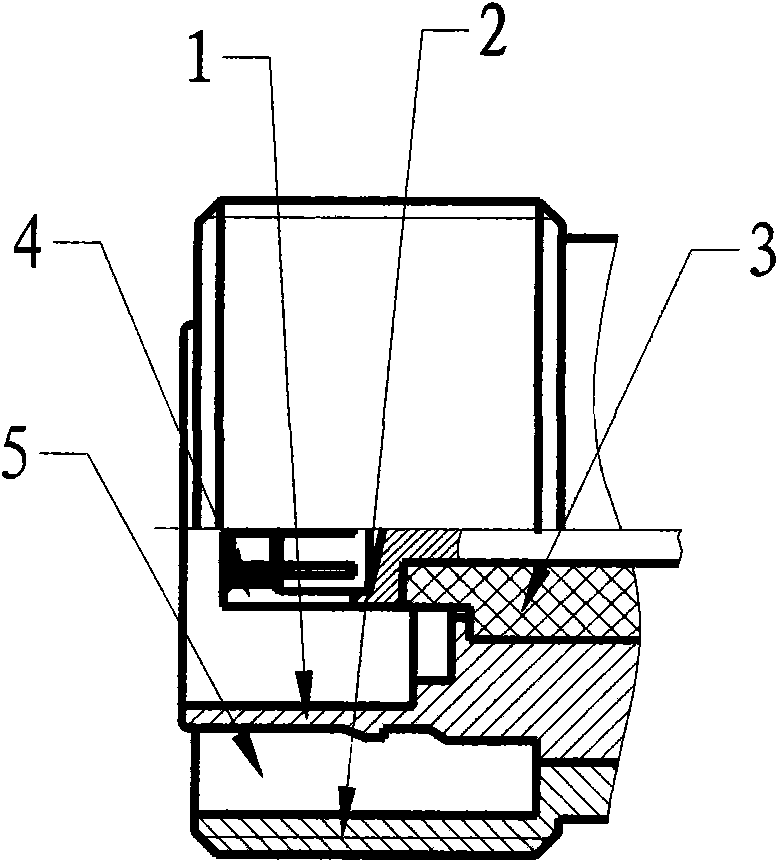

[0025] see figure 1 , a 7 / 16 female connector, including a shell 2, the shell 2 is provided with an outer conductor 1, the inner cavity of the outer conductor 1 is provided with an insulator 3, and the insulator 3 is provided with an inner conductor 4. There is a gap 5 between the outer conductor 1 and the shell 2, and the width of the gap 5 is 3.3-3.4 mm.

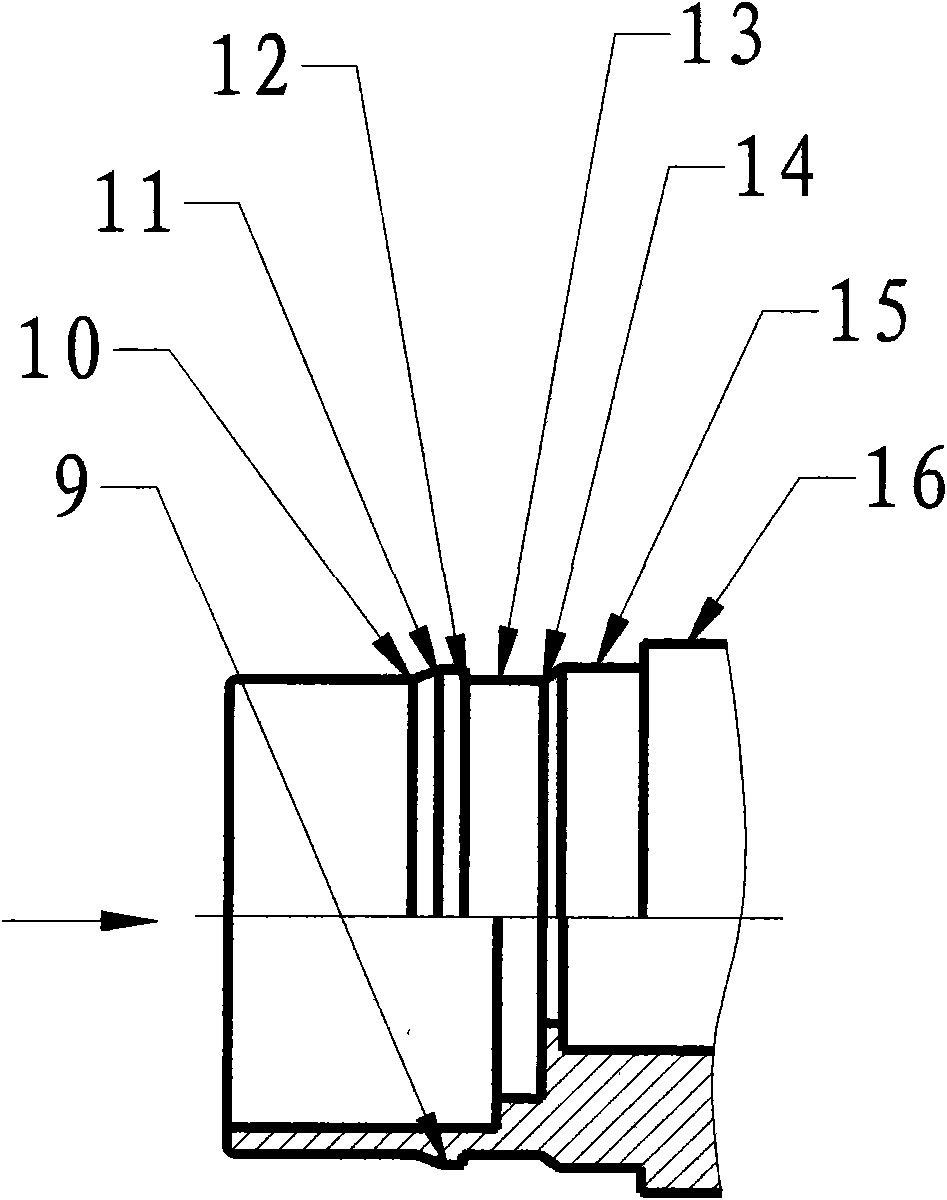

[0026] see figure 2 , 3 , 4, the outer circle of the outer conductor 1 is provided with a bump 9, the length of the bump 9 is greater than or equal to 2 millimeters; the mouth of the bump 9 at the outer end of the outer conductor 1 intersects with the outer circle of the outer conductor 1, and the intersection forms a Groove 10, the groove 10 intersects with the top of the bump 9 at a horizontal angle of 22 degrees to form a circle of intersecting ribs 11, and the inters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com