Sewage treatment unit for sugar orange factory

A sewage treatment device, sugar orange technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, multi-stage water treatment, etc. The effect of speeding up the flow and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

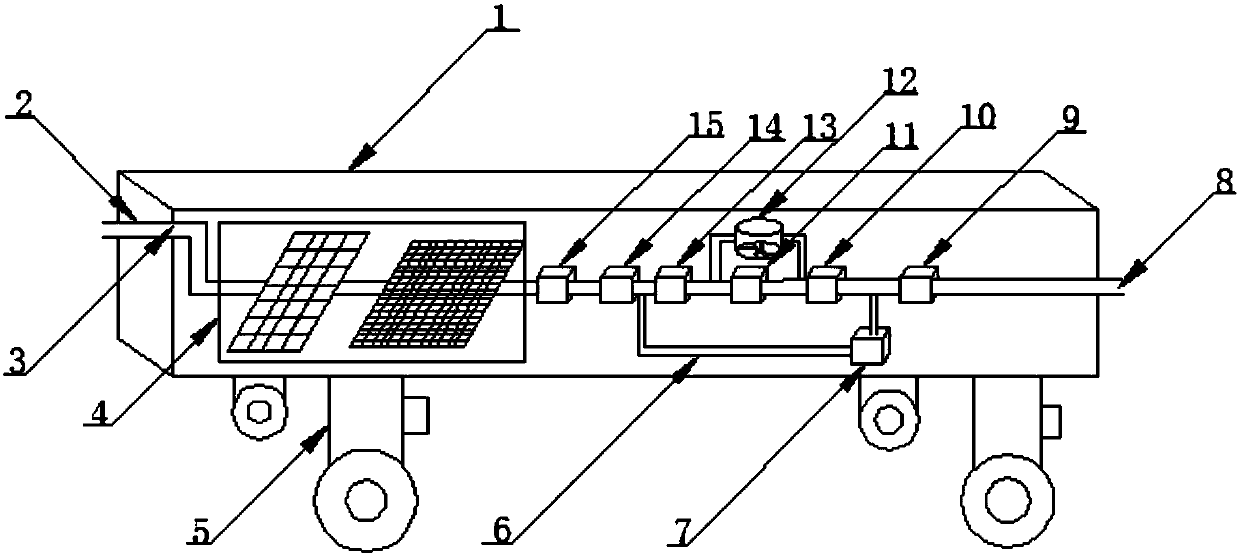

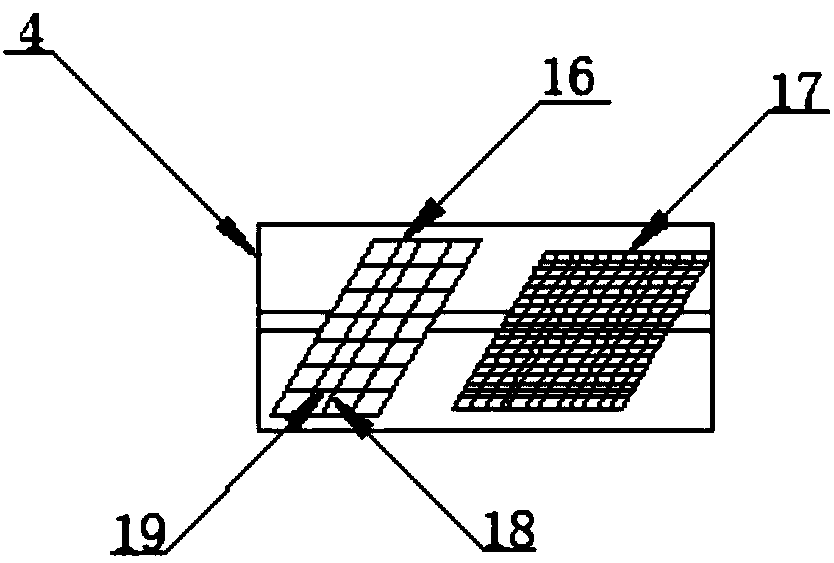

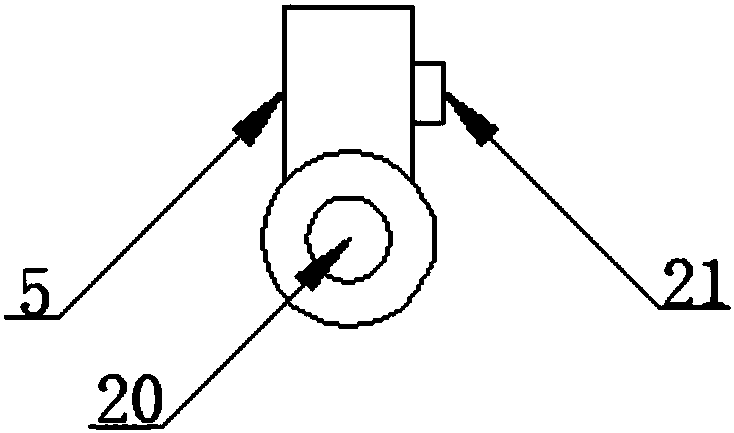

[0019] see Figure 1-4 , the present invention provides a technical solution: a sewage treatment device for a sugar orange factory, including a device housing 1, a water pipe 2, a water inlet 3, a simple treatment area 4, a support column 5, a circulating water pipe 6, a sludge pool 7, an outlet Nozzle 8, disinfection tank 9, secondary sedimentation tank 10, aeration tank 11, blower 12, anaerobic tank 13, anoxic tank 14, grit chamber 15, fine grid 16, coarse grid 17, vertical grid bars 18. Horizontal grille bar 19, universal wheel 20, fixed switch 21, suspension shaft 22, blower casing 23 and blower blade 24, the left end of the device casing 1 is provided with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com