Airborne radar low-pressure test sealing test device

An airborne radar and sealing test technology, which is used in liquid/vacuum measurement for liquid tightness, radio wave measurement systems, instruments, etc., can solve the problem that low-pressure test devices cannot meet the test indicators, etc., and improve the test test. capacity, reduce the weight of the device, improve the durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

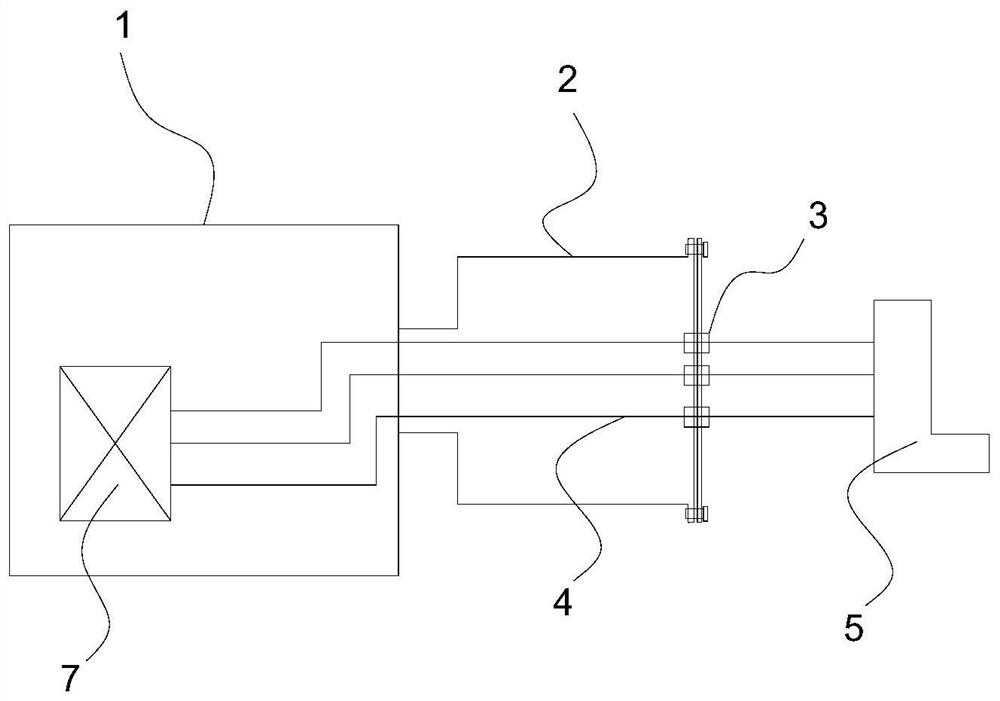

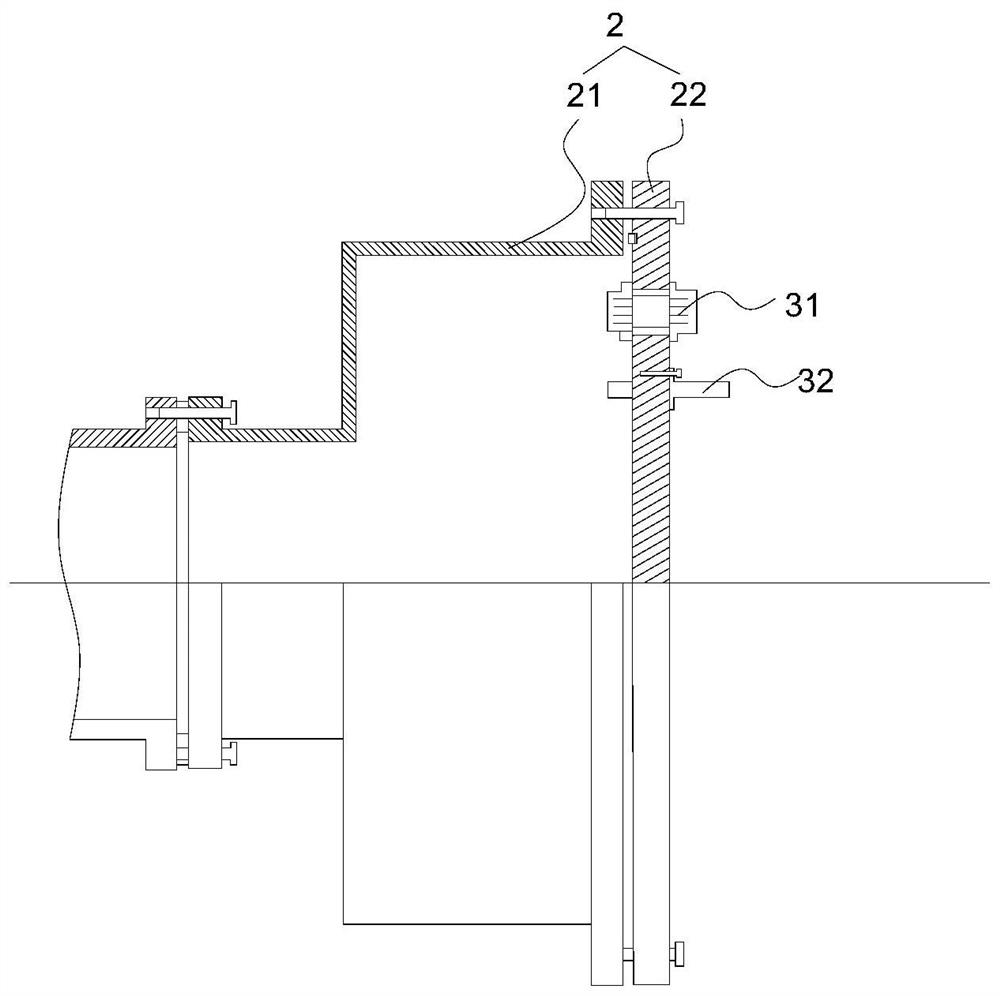

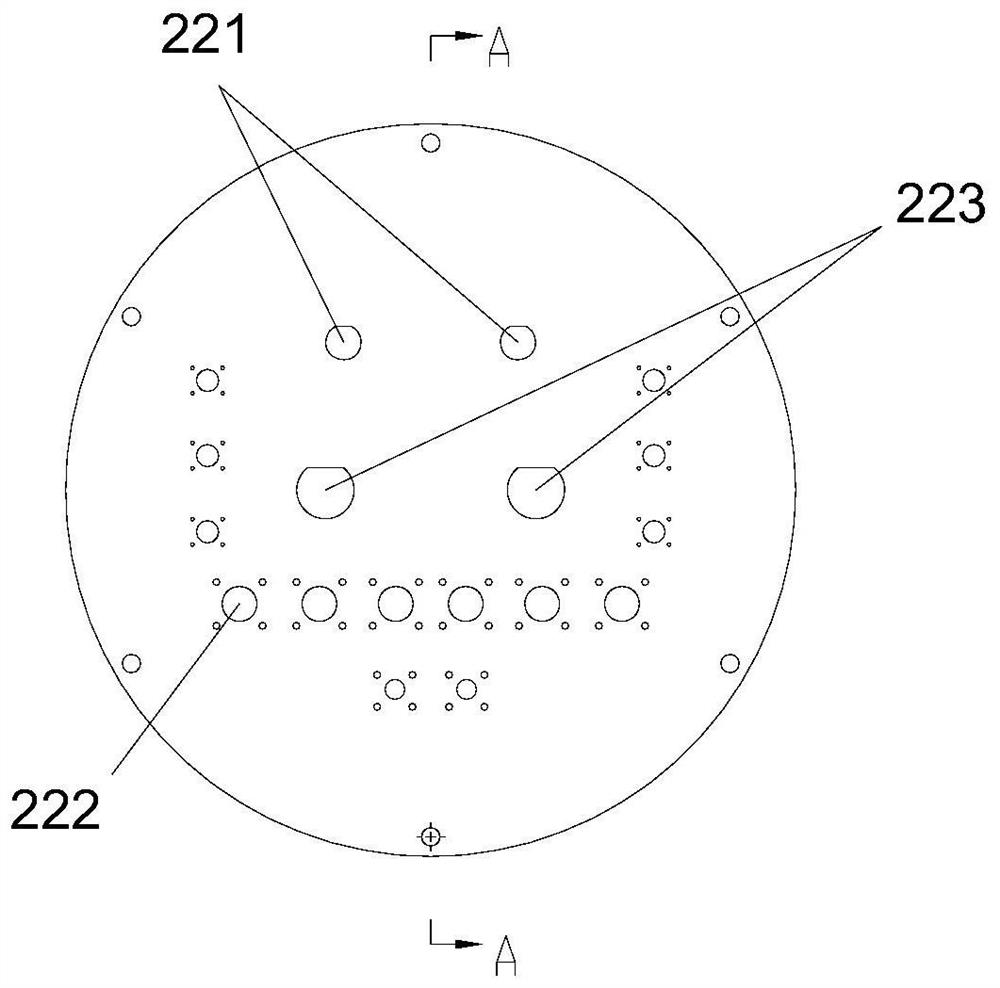

[0039] Such as figure 1 As shown, the airborne radar low-pressure test airtight test device includes a low-pressure test box 1, an expansion device 2, a connector 3, multiple sets of test cables 4, and a test instrument 5; the expansion device 2 is large at one end and small at the other end. Cavity, the small end of the expansion device 2 is an open end, the open end is sealed and connected with the low air pressure test box 1, the expansion device 2 communicates with the low air pressure test box 1, and the large end of the expansion device 2 is a closed end , the closed end has a through installation hole, and the connector 3 is sealed and installed in the installation hole, and each group of test cables 4 is used to connect the test instrument 5, the connector 3 and the airborne radar; the connector 3 is multiple Each set of test cables includes two sections of cables, one of which connects the test instrument 5 and the connector 3 and is located outside, and the other sec...

Embodiment 2

[0050] combine Figure 5 As shown, in this embodiment, on the basis of the first embodiment above, the airborne radar low pressure test sealing test device also includes two liquid adapters 6, and the liquid adapters 6 are sealed and installed in the installation hole at the closed end of the expansion device 2 Inside.

[0051] combine image 3 As shown, two second special-shaped holes 223 are opened in the middle of the test disc 22 , which are circular and arc-shaped, and are used for installing the liquid adapter 6 .

[0052] The airborne radar low pressure test seal test device also includes three cooling water pipes, one of which is connected to one end of the first liquid adapter 6, and the other water pipe is connected to the other end of the first liquid adapter 6 and passed through The expansion device 2 enters the low air pressure test box 1, and then returns to the expansion device 2 from the low air pressure test box 1 and connects the second liquid adapter 2, an...

Embodiment 3

[0055] Such as Figure 6 As shown, the structure of the expansion device 2 in this embodiment is different from that in Embodiments 1 and 2: the small end of the expansion cylinder 21 in this embodiment is a cylindrical cylinder, and the large end is a conical structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com