Organic light emitting diode and packaging effect detection method

A light-emitting diode, an organic technology, applied in the direction of single semiconductor device testing, electrical components, circuits, etc., can solve the problems of low overall yield, low service life, misjudgment, etc., and achieve the effect of scientific detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

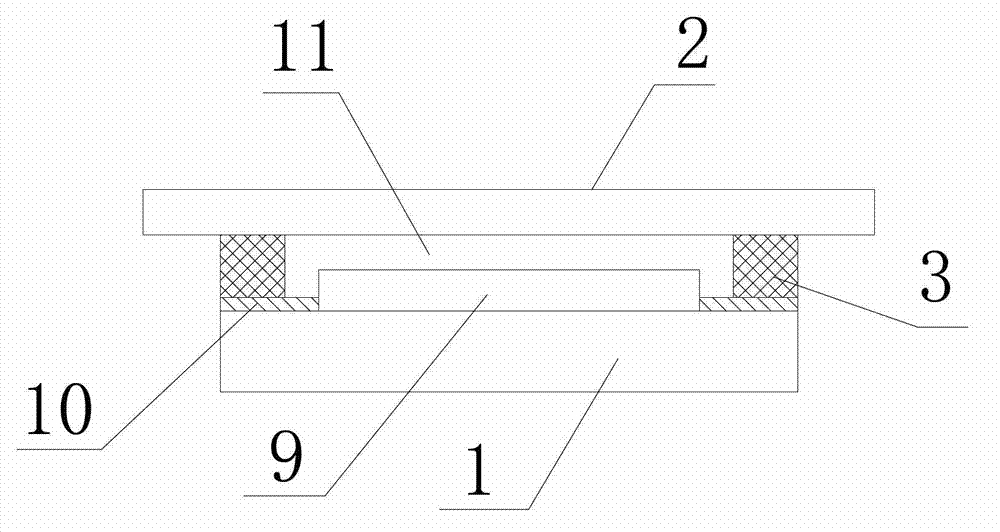

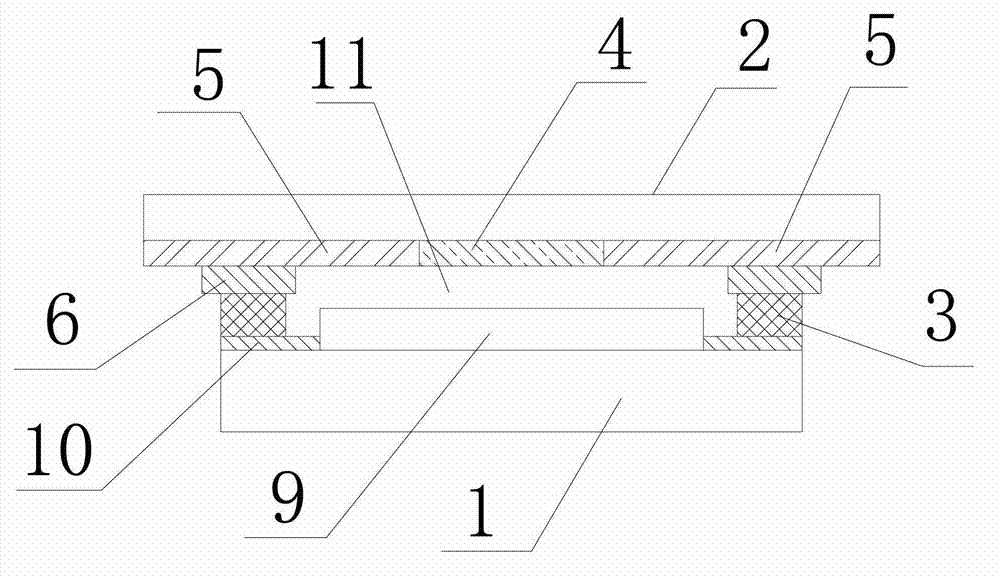

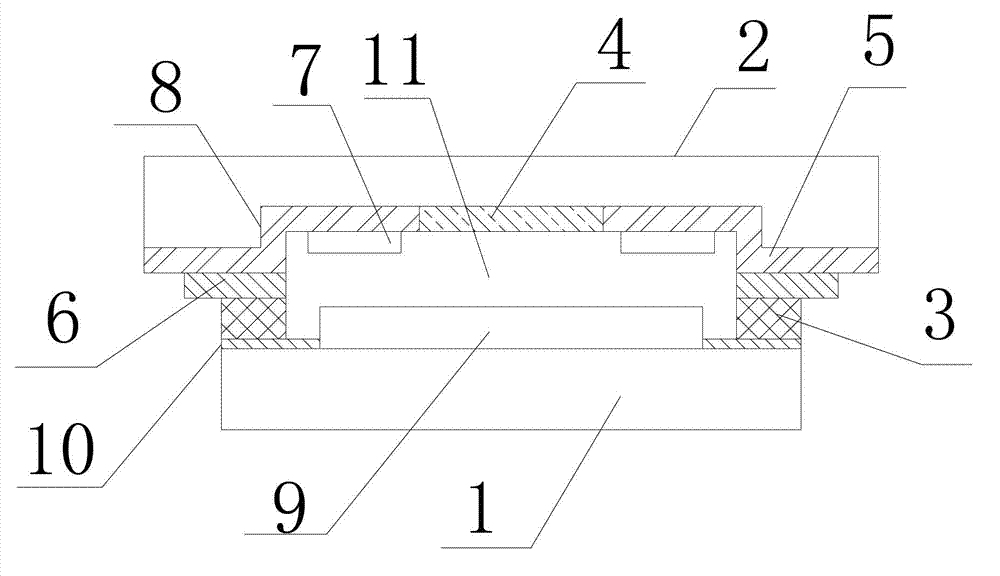

[0022] Such as figure 2 As shown, the sealing layer 3 is arranged to close a circle along the upper surface of the substrate 1 near the edge, the substrate 1 and the cover plate 2 are bonded together through the sealing layer 3 to form a closed cavity 11, and the light-emitting chip 9 is arranged on the substrate 1 on, and in cavity 11. The test strip 4 is arranged in the cavity 11 , and from the perspective of the internal space layout of the cavity 11 and the process, the test strip 4 is preferably arranged on the inner surface of the cover plate 2 . Two ends of the test strip 4 are respectively provided with test electrodes 5 , one end of the test electrode 5 is connected to the test strip 4 , and the other end protrudes to the outside of the cavity 11 . The resistivity of the test strip 4 changes after oxidation, and the greater the change, the more obvious the detection effect. It is generally composed of easily oxidizable metal materials such as calcium or barium.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com