Preparation method and application of pectin enzymatic hydrolysis product having functions of dispelling effects of alcohol and resisting drunk

A pectinase and anti-alcoholic technology, which is applied in the fields of application, food preparation, anti-drug, etc., can solve the problems that have not been reported in the research, so as to expand the scope of application, reduce the degree of esterification and molecular weight, good anti-drunk and anti-drunk effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

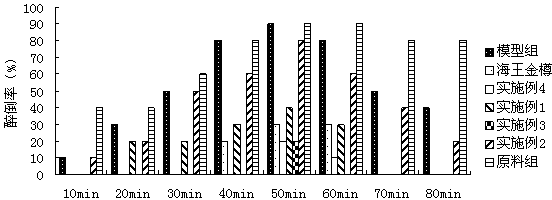

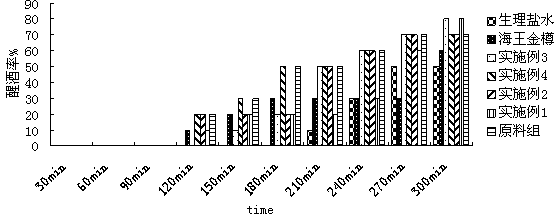

Embodiment 1

[0021] Weigh the high-molecular high-ester pectin powder, pass through a 40-mesh sieve, add water 30 times the dry weight of the pectin powder, stir, heat to 70°C, cool, adjust the pH value to 4, add 0.03% of the dry weight of the pectin powder Pectinase, enzymolysis reaction for 5 minutes, adding pectin esterase with 0.3% dry weight of pectin powder, deesterification reaction for 20 minutes; adjust the pH to neutral, filter to obtain the filtrate, and then add edible alcohol with a mass percentage concentration of 80% Precipitation and filtration were carried out, and the filter residue was repeatedly washed with 80% alcohol by mass percentage, then centrifuged and dehydrated, vacuum-dried and recovered alcohol, crushed, and passed through a 40-mesh sieve to obtain 7.5 g of pectin enzymatic hydrolysis product, with a yield of 75%. The average molecular weight of the product is 68000, and the methoxyl content is 68%. The product was subjected to anti-drunk and hangover animal ...

Embodiment 2

[0023] Weigh high-molecular high-ester pectin powder, pass through a 40-mesh sieve, add water 50 times the dry weight of the pectin powder, stir, heat to 90°C, cool, adjust the pH value to 5, add 0.08% of the dry weight of the pectin powder Pectinase, enzymolysis reaction for 30 minutes, adding pectin esterase with 0.8% dry weight of pectin powder, deesterification reaction for 70 minutes; adjust the pH to neutral, filter to obtain the filtrate, and then add edible alcohol with a mass percentage concentration of 80% Precipitation and filtration were carried out, and the filter residue was repeatedly washed with 80% alcohol by mass percentage, then centrifuged and dehydrated, vacuum-dried and recovered alcohol, crushed, and passed through a 40-mesh sieve to obtain 9.2 g of pectin enzymatic hydrolysis product, with a yield of 92%. The average molecular weight of the product is 9000, and the methoxyl content is 12%. The product was subjected to anti-drunk and hangover animal expe...

Embodiment 3

[0025] Weigh the high-molecular high-ester pectin powder, pass through a 40-mesh sieve, add water 40 times the dry weight of the pectin powder, stir, heat to 80°C, cool, adjust the pH value to 5, add 0.04% of the dry weight of the pectin powder Pectinase, enzymolysis reaction for 10 minutes, adding pectin esterase with 0.4% dry weight of pectin powder, deesterification reaction for 30 minutes; adjust the pH to neutral, filter to obtain the filtrate, and then add edible alcohol with a concentration of 80% by mass Precipitation and filtration were carried out, and the filter residue was repeatedly washed with 80% alcohol by mass percentage, then centrifuged and dehydrated, vacuum-dried and recovered alcohol, crushed, and passed through a 40-mesh sieve to obtain 9.0 g of pectin enzymatic hydrolysis product with a yield of 90%. The average molecular weight of the product is 26000, and the methoxyl content is 35%. The product was subjected to anti-drunk and hangover animal experime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com