A kind of method for preparing pectin disaccharide and pectin triose

A technology of pectin and low-ester pectin, which is applied in the field of sugar bioengineering, can solve the problems of low yield of pectin oligosaccharides, high viscosity of reaction system, difficult mass transfer of enzyme reaction, etc., to achieve enhanced solubility and increased content , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Water heat treatment and enzymatic coupling lower ester concrete preparation of adult sugar and pectin triose, the specific steps are as follows:

[0023] (1) Weigh 1G low ester glue (less than 50%) in a 35 mL cooking tank, adding distilled water from 1: 25 (g / ml), in the oil bath pan at 140 ° C. 30min, fast cooling, centrifugation, taking the supernatant.

[0024] (2) Adjusting the supernatant to pH 5.5 obtained by dilute hydrochloric acid to pH 5.5, the inner segregation enzymes of 15, 65 and 115u / g gum are added, and the enzymatic solution is enzymatically resolved at 45 ° C. After the end, the enzyme is allowed to activate 10 min, centrifugally, and take the supernatant in boiling water. It is shown in Table 1 with high performance liquid phase ion chromatography.

[0025] Table 1 Low ester gel water heat treatment with enzymatic coupling degradation pectin diose and pectin triose yield

[0026] Endogeneous rubber enzyme dosage (U / G pectin) Pectin diose ...

Embodiment 2

[0029] The esterification degree of esterification after oligate gel is heated, and the steps are as follows:

[0030] (1) Weigh 1G low ester glue (less than 50%) in a 35 mL cooking tank, adding distilled water from 1: 25 (g / ml), in the oil bath pan at 140 ° C. 30min, quick cooling, centrifugation, taking the supernatant, dry water, and dry with the pectin sample before the water heat treatment.

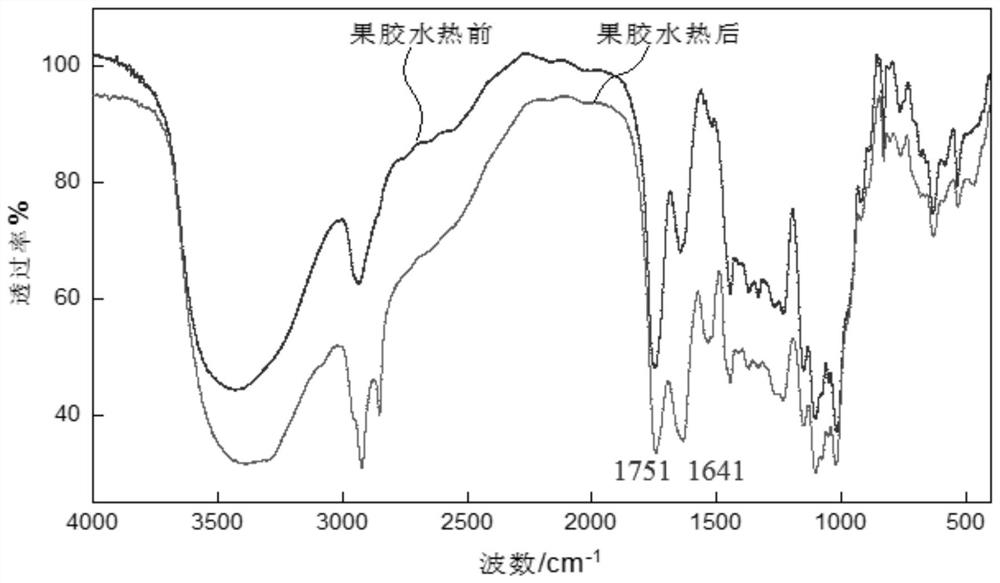

[0031] (2) Take step (1) in vacuum dry water pretreatment before and after, KBR polishing tablets, using Fourier transform infrared spectrometer in 4000-400 cm -1 Scanning within the range, the results analysis figure 1 .

[0032] Depend on figure 1 It can be seen, 1751cm -1 The absorption peak at the point indicates the esterified carbonyl group, 1641cm -1 The absorption peak at the point indicates an unsterified carbonyl group, and the absorption intensity of the unsolved carbonyl is not esmified after the hydrothermal pre-treatment is significantly enhanced than the pectin before th...

Embodiment 3

[0040] 1. Water heat treatment and enzymatic coupling lower ester confection with enzymatic adhesive and pectin triose, the specific steps are as follows:

[0041] (1) Weigh 1G low ester pump (esterification degree below 50%) in a 35 ml cooking tank, add distilled water from 1:25 (g / ml), in the oil bath pan, in the oil bath, 100 ~ 180 ° C 30 min, quickly cool, centrifuge, and take the supernatant.

[0042] (2) Adjusting the supernatant to pH 5.5 by dilute hydrochloric acid to pH 5.5, the inner segregation enzyme of 15 U / G pectin is added, and the enzymatic solution is added at 45 ° C, and after the enzymatic reaction is completed, the boiling water Medium enzyme is 10 min, centrifuged, and taking the supernatant. It is shown in Table 3 with high performance liquid phase ion chromatography.

[0043] 2, hydrothermal method degradation of low ester concrete preparation of adhesive oxose and pectin trisaccharide: 1. 1G low ester pump (esterification degree below 50%) in 35ml steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com