Supporting flow guide plate and separation filtering membrane column device

A technology of separation filtration and deflector plate, which is applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems of reduced membrane column life, high energy consumption of system operation, and anti-pollution of membrane column, so as to reduce Effects of load intensity, improvement of product efficiency, and expansion of operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

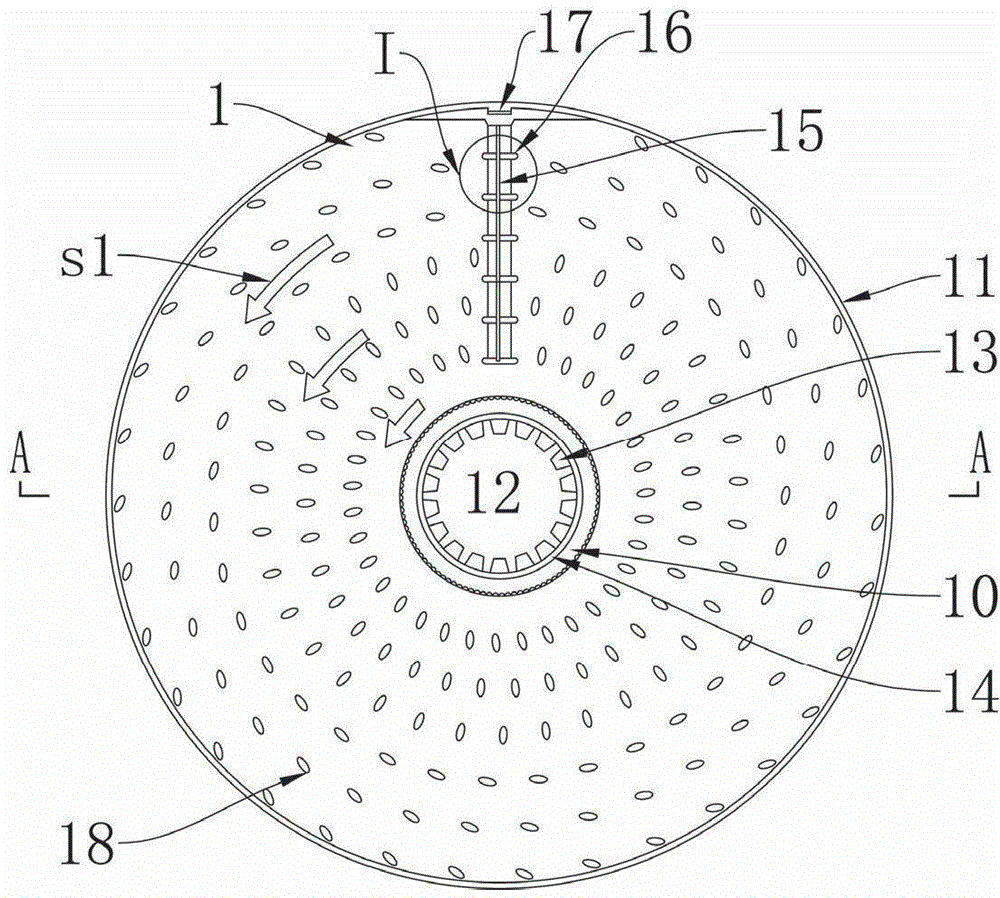

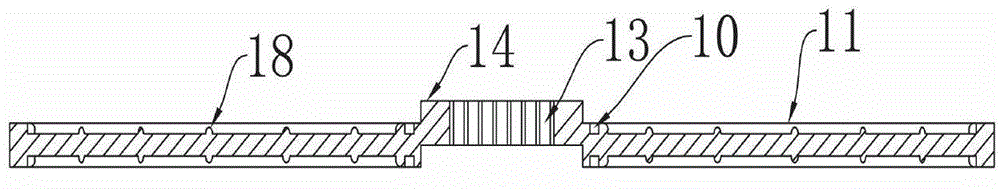

[0031] Embodiment 1: see Figure 1 to Figure 4 . figure 1 A supporting deflector is shown, and an outer rim 11 of a ring structure is provided on both sides of the supporting deflector 1 . The upper surface of the supporting deflector 1 is provided with an inner rim 14 of toroidal structure. The supporting deflector plate 1 is a disc with a central hole 12 concentric with the disc at its center.

[0032] Both sides of the disk are provided with six circles of flow-blocking bumps 18 , and each circle is evenly distributed with a plurality of flow-blocking bumps 18 . The anti-flow protruding point 18 semi-ellipsoid or the bottom surface of the anti-flow protruding point 18 is an ellipse, and the top is a protrusion with a smooth arc surface; The short diameter of the flow-blocking protruding point 18 on the edge of the disk coincides with the radius line of the disk. The flow blocking protrusions 18 surround the installation hole 12 and are concentrically dispersed. At the ...

Embodiment 2

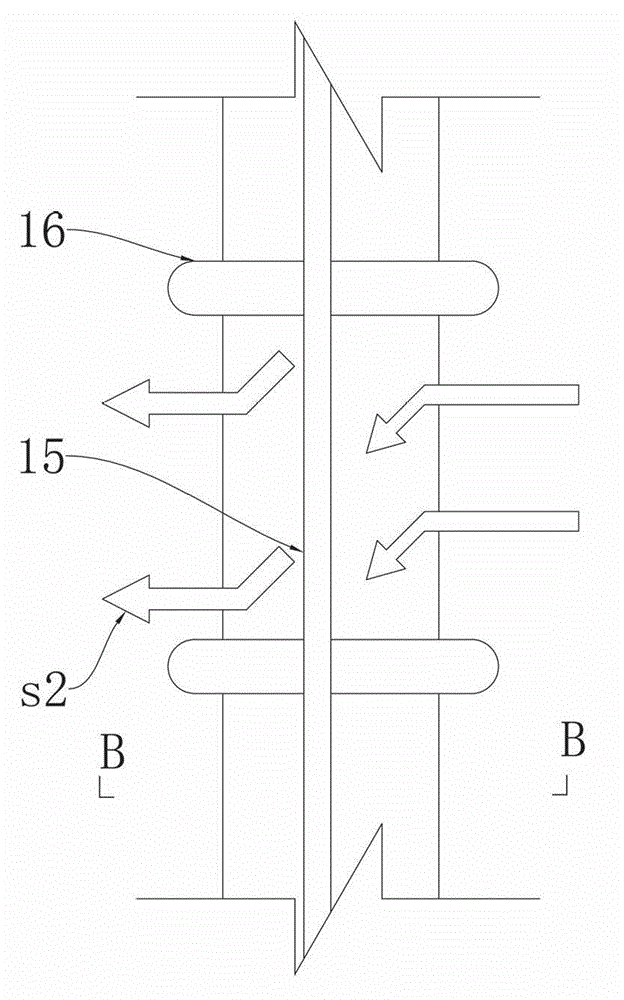

[0038] Example 2: see Figure 5-Figure 10 . The separation and filtration membrane column device 3 described in this embodiment includes the supporting deflector plate 1 described in the embodiment. The separation and filtration membrane column device also includes a circular tube pressure-bearing shell 30 sealed by an upper end cover flange 39 , an upper fluid reverse disc 37 , a lower fluid reverse disc 36 , and a lower end cover flange 38 . The pressure-bearing shell 30 is equipped with an outer pull rod 43 for supporting and tightening the upper end cover flange 39 and the lower end cover flange 38 . The center of the upper end cover flange 39 , the upper fluid reverse disc 37 , the lower fluid reverse disc 36 and the lower end cover flange 38 is provided with a hole for the inner pull rod 31 to pass through. An inner tie rod 31 , an upper stacking plate 35 and a lower stacking plate 34 are installed in the pressure-bearing shell 30 for fastening and supporting the defle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com