Baking method and device of ladle

A baking device and molten steel tank technology, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of large heat loss, flame spraying, complex structure, etc., to reduce heat loss, improve thermal efficiency, Avoid the effect of flames running up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

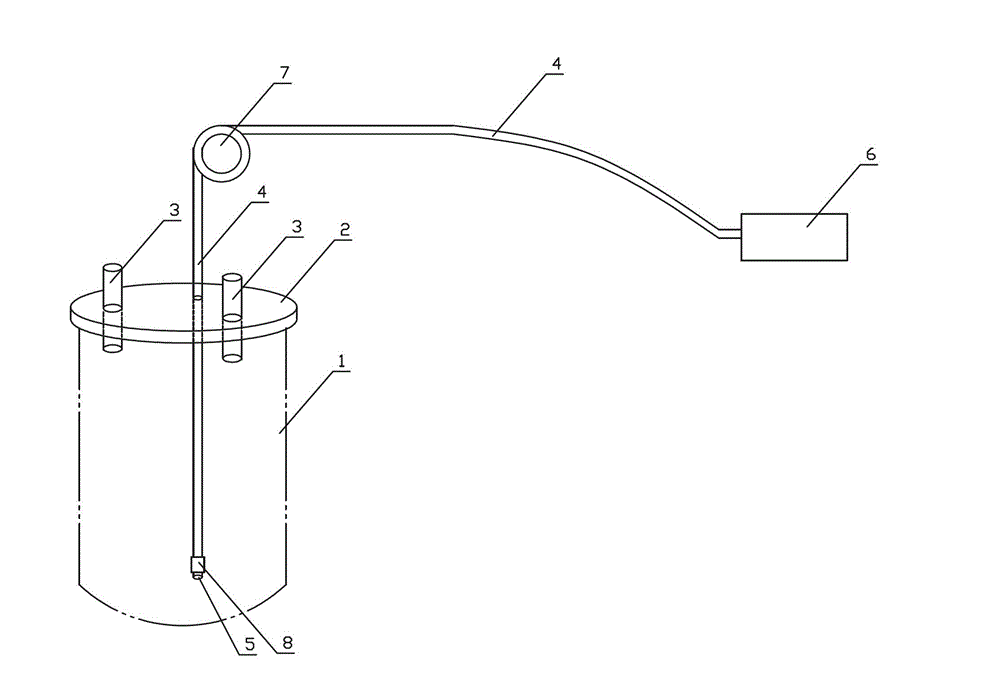

[0019] See figure 1 , is a structural schematic diagram of the implementation state of a baking device for a molten steel tank according to the present invention, including a molten steel tank 1, a baking cover 2 and two burner nozzles 3, the baking cover 2 is provided with an air extraction pipe 4, and one end of the air extraction pipe 4 A metal mesh 5 is provided with a mesh size of 2-3mm. The metal mesh plays a protective role to prevent clogging of inhaled residue during work. The other end of the exhaust pipe 4 is connected to the vacuum pump 6, and the diameter of the exhaust pipe 4 is 40-50mm. The air extraction pipe 4 is wound on the reel of the electric take-up device 7 . One end of the air extraction pipe 4 is provided with a counterweight 8, so that the air extraction pipe 4 can be lifted and lowered reliably under the action of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com