Thermal insulation material mortar coating technology

A thermal insulation material and process technology, applied in the direction of pressing rollers, etc., can solve problems such as human body and environmental hazards, open flames, bad construction habits, etc., and achieve the effect of enhancing strength and increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

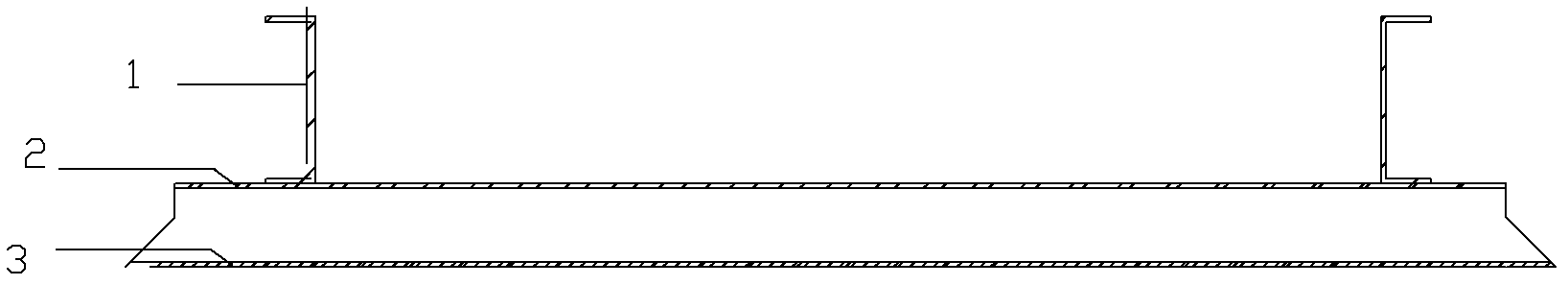

[0022] Such as figure 1 As shown, the baffle plate 1 is located on both sides of the forward direction of the pallet 2, and its fixing function.

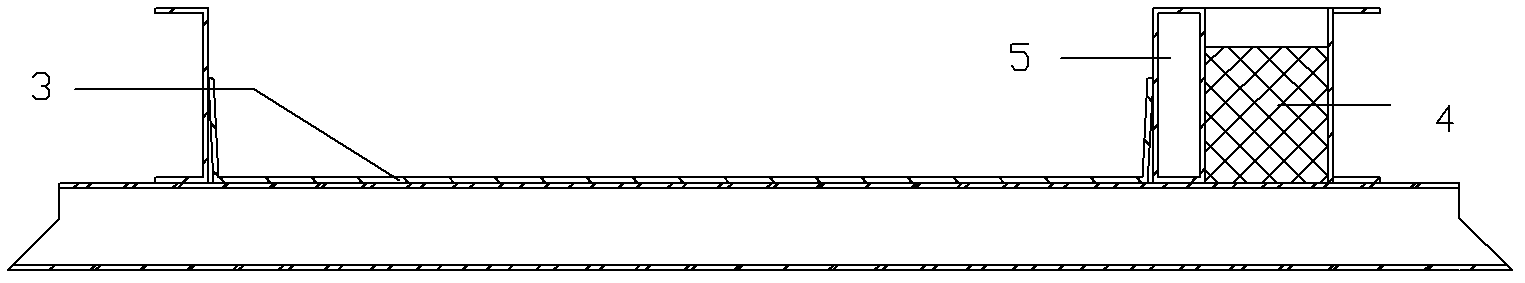

[0023] Such as figure 2 As shown, the positioning mold 3 is placed between two baffles 1, and a wooden wedge 4 and an aluminum alloy square tube 5 are added to one side of the baffle 1 for reinforcement according to the size of the insulation material.

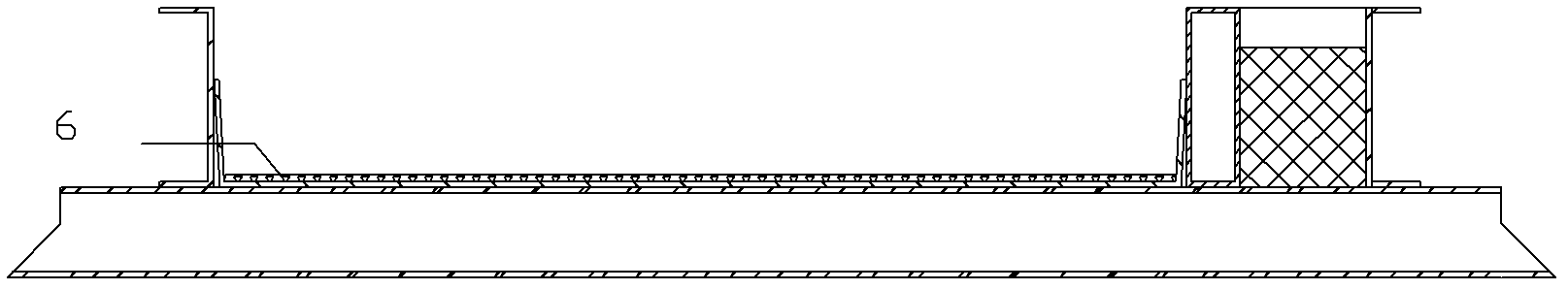

[0024] Such as image 3 As shown, the first layer of mortar 6 is applied on the ground of the positioning mold 3 .

[0025] Such as Figure 4 As shown, the insulating material 7 that has been drilled is placed on the upper surface of the first layer of mortar 6 that has been smeared.

[0026] Such as Figure 5 As shown, the second layer of mortar 8 is poured on the upper surface of the insulation material 7, and the mortar is smoothed by the homogenizing device of the slurry coating device, and the excess mortar will flow into the gap between the insulation material 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com