Flat plate type seam die coating machine

A coating machine, flat-plate technology, applied in the direction of coating, flat products, household utensils, etc., can solve the problems of waste materials, high operating costs, bulky, etc., to reduce the amount of inherent waste, avoid secondary pollution, The effect of the small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

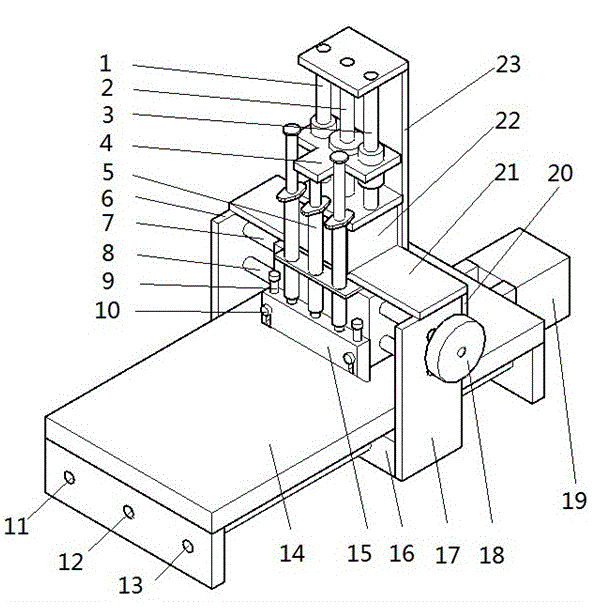

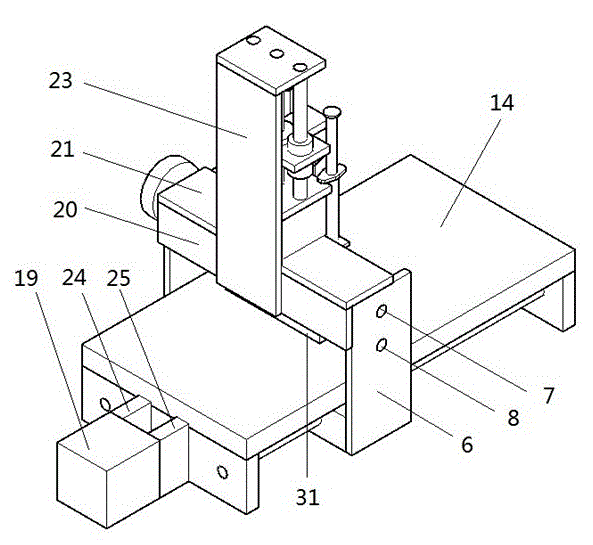

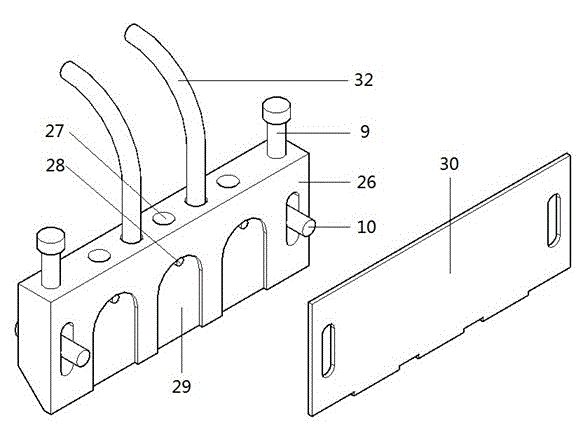

[0026] Such as Figure 1 to Figure 3 As shown, the flat-bed slot die coater involved in the present invention is mainly composed of a film-forming unit driven by a film-forming stepping motor 19, a Y-axis positioning unit regulated by a hand wheel 18, and a solution injection unit driven by an injection stepping motor 22. , And the gap adjustment device and the slot die cutter 15 are composed. The film-forming stepping motor 19 drives all the parts fixed on the X-axis slider 16 to move along the X-axis direction; rotating the handwheel 18 can move the parts fixed on the Y-axis to move along the Y-axis, thereby realizing the positioning of the slot die outlet The injection stepper motor 22 drives the push block 4 to move along the Z-axis direction, and then pushes the syringe 5 to inject the solution into the slot die cutter 15; the adjustment bolt 9 and the fastening bolt 10 are used in conjunction with the adjustable gap between the slot die outlet and the substrate distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com